AI for Manufacturing Quotation: How Manufacturers Can Beat Quoting Delays & Costing Challenges

Businesses that use AI in their quoting procedures have seen a 70% reduction in quoting time, higher conversion rates, and increased profits. This blog examines the strategic benefits of AI-powered cost estimating, the inefficiencies of traditional quoting, and the observable return on investment that manufacturers can achieve.

Facing Quote Delays, Manual Costing Bottlenecks, And Lost Deals? See How Our Predictive Maintenance AI Software Solutions Fix It All

“The world has changed for manufacturers. Growth in the US manufacturing sector, for example, had languished at 1.4% over the past two decades. More recently, AI, digital technologies, sustainable features, and higher skills have reinvigorated the market: over the past five years, US industrial companies have generated total shareholder returns about 400 basis points higher than in the previous 15 years.”– McKinsey

Why Repeating Quotes Costs You More: Let AI for Manufacturing Quotation Help You Price Better

Quoting is more repetitious than challenging in most custom manufacturing settings. Businesses rewrite the same emails, recalculate the same logic, and double-check the same numbers. They are simply rearranging the task they have previously completed, which slows down the process.

Automated pricing can be effective, but only if it accurately represents how businesses quote. Businesses may quickly match their quoting engine with the actual price by using AI for manufacturing quotation. The system learns from actual prices and makes automatic adjustments, so there’s no need to guess margins or overthink machine settings.

The outcome?

Quicker setup, reliable quotations, and assurance that each price feels correct, all without the need for spreadsheets or trial and error.

The Old Way of Quoting: Challenges Before AI for Manufacturing Quotation

Before we go on to the exciting new AI-powered future, it’s important to keep in mind why the current method is so painful. The conventional quoting procedure is a major waste of resources. It is labor-intensive, laborious, and mostly dependent on the “tribal knowledge” of a small number of skilled estimators or engineers.

The main challenges were as follows:

- Slow Response Times: This is lethal. Your competitors who are quicker on the draw are picking up the business while you’re spending days or even weeks creating a quote. Opportunities are wasted due to delays.

- Complex Configurations: Customers desire personalized items. This indicates that each quote is a one-of-a-kind project due to various specifications, supplies, and other factors. This is a nightmare to calculate manually.

- Inconsistent Pricing: Have you ever received two separate quotes from the same business for the same job? It does occur. Confusion and a lack of confidence may result from different sales representatives applying different discounts or calculating things differently.

Why Should Manufacturers Deploy Agentic AI?

Accuracy and speed are key components of manufacturing. Leaders and laggards have always been distinguished by AI. However, the goal of Agentic AI in manufacturing is survival rather than technological superiority.

- Manufacturing Transformation: AI-powered predictive maintenance lowers repair costs by 40% by reducing downtime. Within the next five years, 35% of manufacturers are anticipated to use AI agents to perform essential operations.

- Autonomous Operations: AI agents in manufacturing boost productivity by automating production processes, keeping an eye on quality control, and reducing downtime.

- Cost Reduction Impact: Supply chain optimization AI for manufacturing quality control are two applications of AI agents in logistics; businesses have reported cost savings of up to 30%.

How Does AI Manufacturing Quotation Automation Work?

- Rule-based Configuration: To ensure precise cost calculations for customized engineering, bulk order discounts, and market-specific pricing, pre-established business rules are integrated with AI models and BOM data.

- Workflow & Approval: Automatically process quotes via the required protocols and approvals. This leads to a quicker, error-free approval process that ensures compliance, cuts down on delays, and gives visibility into the status of every quote.

- Automated Quote Generation: It can compute precise costs, analyze and configure complicated products, and provide ready-to-send quotes based on client criteria.

- Centralized Data Integration: Integrates information from ERP, CRM, and other systems about products, prices, inventories, and customers.

Check our Success Story: Accelerating Valuation Through AI-Enabled New Product Strategy for a Manufacturing AI and Data Platform

Benefits of AI for Manufacturing Quotation

Businesses can gain significant benefits by using Generative AI for manufacturing quotation to automate and compare quotes received through phone, fax, and email. It helps streamline communication, reduce manual effort, improve accuracy, and speed up decision-making for faster order conversions.

1. Error-Free Orders & Increased Efficiency

To avoid expensive errors and conflicts, generative AI for manufacturing quotation ensures that the final order always matches the quotation.

Sales and customer support staff can concentrate on higher-value tasks since AI reduces the human effort required to review and process customer changes. Information is automatically and 100% accurately matched and mapped between orders, quotations, and ERP systems rather than being done manually.

2. Faster Processing

AI-powered automation goes beyond simply matching and mapping quotation data by executing the final order in your ERP systems quickly. AI makes sure that the final order is automatically entered into the system in real-time and with complete correctness once it has been confirmed.

This speeds up the entire order fulfillment process and removes any delays brought on by manual data entry, freeing up your team to concentrate on more strategic tasks.

3. Enhanced Accuracy and Reduced Errors

Due to human error, manual quotation procedures might result in inaccurate price and cost estimation. Advanced algorithms are used by AI-powered quoting systems to carefully examine enormous amounts of data.

AI systems produce accurate quotes with few errors by considering variables such as labor costs, production schedules, raw material costs, and other relevant considerations. In the end, this improved precision increases profitability and builds consumer trust by reducing the possibility of overpricing or underpricing products.

4. Improved Pricing Strategies

AI-powered quoting systems use historical data, machine learning, and predictive analytics to give accurate cost estimates. By reviewing material costs, labor needs, machine use, and overheads, AI for manufacturing quotation helps manufacturers set the right price. This reduces the risk of underpricing, protects profits, and keeps them competitive.

Real-time quoting with AI also supports dynamic pricing by tracking market demand, competitor prices, and other key factors. This helps manufacturers increase profit margins and stay ahead of the competition.

Tired Of Inaccurate Estimates, Material Cost Fluctuations, And Complex BOM Pricing? Transform Quoting with AI Now

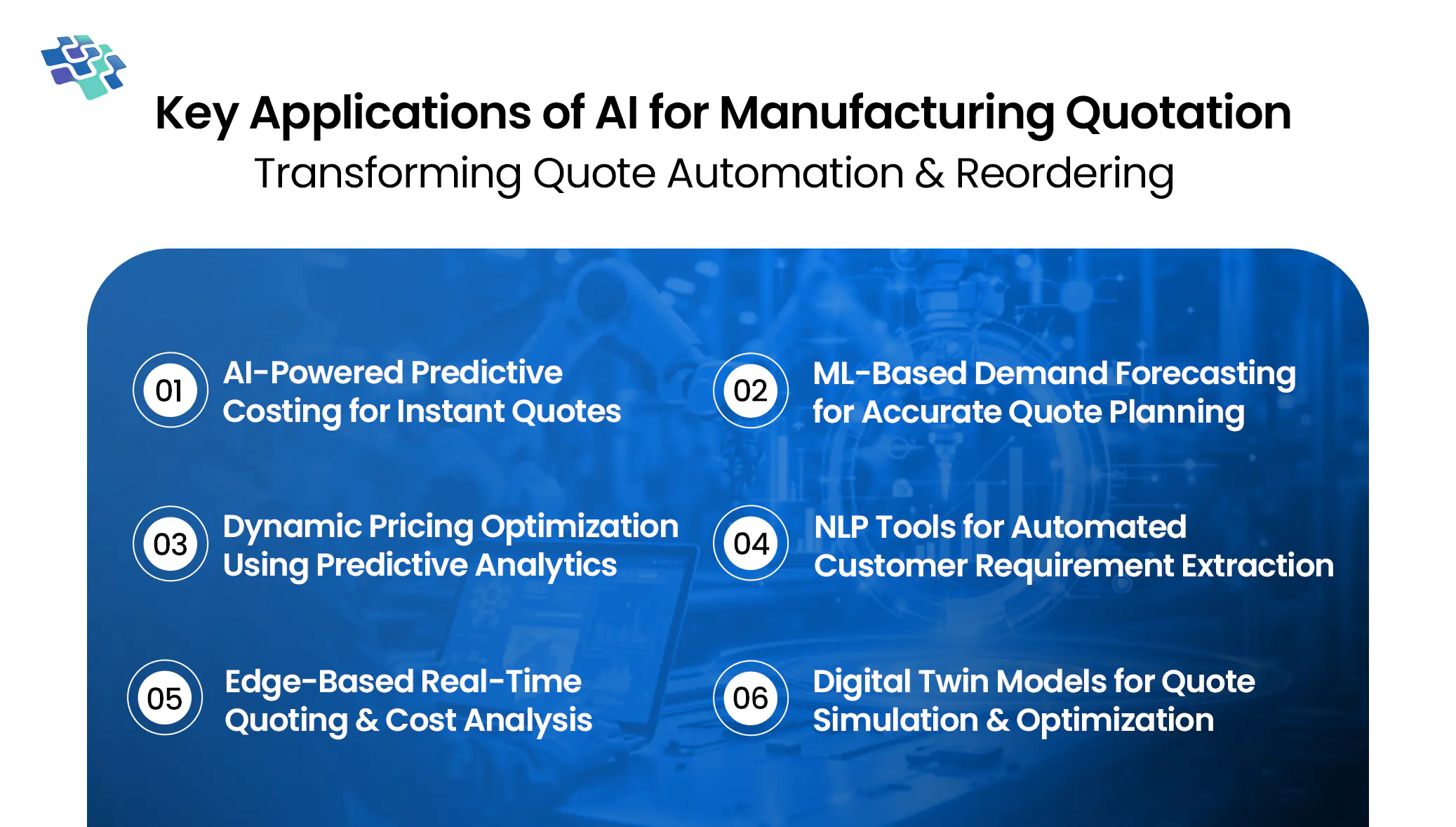

AI for Manufacturing Quotation: Key Applications Revolutionizing Quoting, Pricing & Reordering

AI applications for real-time quoting use machine learning, natural language processing, and predictive analytics to create accurate and fast quotations. These applications help businesses reply quickly to customer requests, improve pricing, and automate the quote process. Here are some key AI for manufacturing quotation applications used for real-time quoting:

1. AI-Powered Predictive Costing for Instant Quotes

1. AI-Powered Predictive Costing for Instant Quotes

Quote management and predictive costing are two of the main benefits of AI for manufacturing quotations. Large volumes of historical data, including previous quotations, actual production costs, changes in raw material prices, and labor hours, can be analyzed by AI and ML. AI uses this information to create prediction models that provide extremely precise cost estimates for future projects.

To produce accurate, data-driven insights, it considers every aspect, such as labor costs, material costs, machine run times, and overheads. This reduces the time needed for cost estimation, gets rid of assumptions, and improves accuracy.

2. ML-Based Demand Forecasting for Accurate Quote Planning

Regression models, time series analysis, and neural networks are examples of machine learning approaches that assist manufacturers in estimating client demand. To provide precise future demands, machine learning algorithms examine past sales data, industry trends, seasonal variations, and other pertinent elements.

Manufacturers can use these forecasts to optimize production schedules, allocate resources, and modify pricing strategies in response to shifting market conditions. Overproduction, inventory expenses, and operational inefficiencies can all be eliminated.

3. Dynamic Pricing Optimization Using Predictive Analytics

Pricing strategies are dynamically optimized by AI predictive analytics algorithms using real-time information, market conditions, and historical data. To find the best pricing for a specific service or product, these algorithms can examine variables including demand, competition, market trends, and consumer behavior.

Businesses can maximize profitability while maintaining their competitiveness and responsiveness to client expectations by constantly observing and adjusting to shifting market conditions.

4. Generative AI for Automated Customer Requirement Extraction

Generative AI plays a significant role in AI for manufacturing quotation by helping businesses read and understand customer requests from unstructured data. These requests often come through emails, chat messages, web forms, or online inquiries. Generative AI uses methods like text mining, sentiment analysis, and named entity recognition to pull out key details from customer communication. This includes product specifications, quantities, delivery timelines, and customer preferences.

By automatically gathering this information, businesses can reduce manual effort and avoid errors. It also supports the creation of accurate, clear, and personalized quotations based on each customer’s needs. As a result, response times improve, and customers receive faster and more relevant quotes.

5. Edge-Based Real-Time Quoting & Cost Analysis

Edge analytics is another valuable part of AI manufacturing quotation, as it helps manufacturers get quick insights from machine data in a fast and decentralized way. Sensors installed on machines collect data in real time, and edge analytics processes this data instantly at the source. This reduces delays, speeds up decision-making, and cuts the time needed to turn data into useful insights.

In manufacturing, edge analytics supports three key applications:

- Improves production quality and yield by spotting issues early.

- Detects early signs of machine performance drops or failures.

- Helps track worker health and safety through smart wearables, creating a safer workplace.

6. Digital Twin Models for Quote Simulation & Optimization

Digital twins play a key role in AI for manufacturing quotation by creating virtual copies of machines, products, or full production lines. These digital models use AI to generate synthetic data and run simulations of different manufacturing situations. The data produced from these simulations is then used to train AI models, making them more accurate and reliable.

By testing various conditions, design changes, and outcomes in a virtual environment, manufacturers can identify the best methods before making real changes on the factory floor. This reduces the need for physical trials, lowers cost, and helps improve processes, product quality, and quoting accuracy for future production runs.

Dealing With Inconsistent Pricing, Manual Data Entry, And High Quote Revisions? Let Artificial Intelligence Software Development Services Solve It

The Future of AI for Manufacturing Quotation

The role of AI in manufacturing quotation and cost estimation will expand further, bringing smarter automation, real-time pricing, greater accuracy, and more data-driven quotes. Future innovations will help manufacturers create faster, competitive, and highly personalized quotations with improved cost control:

- Integration with Digital Twins: Using digital twin technology, manufacturing processes can be virtually replicated. An AI-powered digital twin can simulate new production techniques and offer real-time cost insights.

- Sustainability-Focused Costing: AI will increasingly consider environmental considerations, helping manufacturers in cost optimization while achieving sustainability goals.

- Greater Personalization: AI systems will become more flexible to meet the demands of certain manufacturers, providing highly customized cost estimation services.

How NextGen Invent Can Boost Accuracy and Speed in AI-Driven Manufacturing Quotation

The use of AI for manufacturing quotation not only improves the speed and accuracy of quoting but also gives manufacturers a strong competitive edge. With AI-driven automation, businesses can respond faster to changing market needs through demand analysis, historical quote lookup, cost forecasting, and risk control. This reduces customer drop-offs and helps win more orders. As AI continues to evolve and more data becomes available, automated quotation systems will become even smarter and more precise. This results in unlocking new profit and growth opportunities for manufacturers.

With our Artificial Intelligence software development services, NextGen Invent helps manufacturers speed up quoting processes, improve accuracy, and unlock higher sales efficiency.

- Real-time dynamic pricing: Adjust prices instantly using real-time data such as add-ons, discounts, and changing material costs. Maintain profitability while offering fair, competitive, and transparent quotes.

- Accurate BOM handoffs to suppliers: We build solutions that auto-generate accurate and structured BOMs for every quote. This enables faster, error-free handoffs to suppliers, reduces lead times, and improves coordination for sales, procurement, and production teams.

- Self-service and guided quoting: Let customers create instant, error-free quotes without sales involvement. This reduces admin workload, speeds up the buying cycle, and delivers a smooth online quoting experience.

Ready to take your quoting process from good to great with AI? Contact us at NextGen Invent and let us help you get there faster.

Frequently Asked Questions About AI for Manufacturing Quotation

Related Blogs

How AI in Manufacturing is Transforming the Industry?

A fiercely global economy can be kept competitive with the advent of AI in manufacturing industry. The integration of artificial intelligence in manufacturing brings transformative potential, employing algorithms to process data from sensors and human inputs.

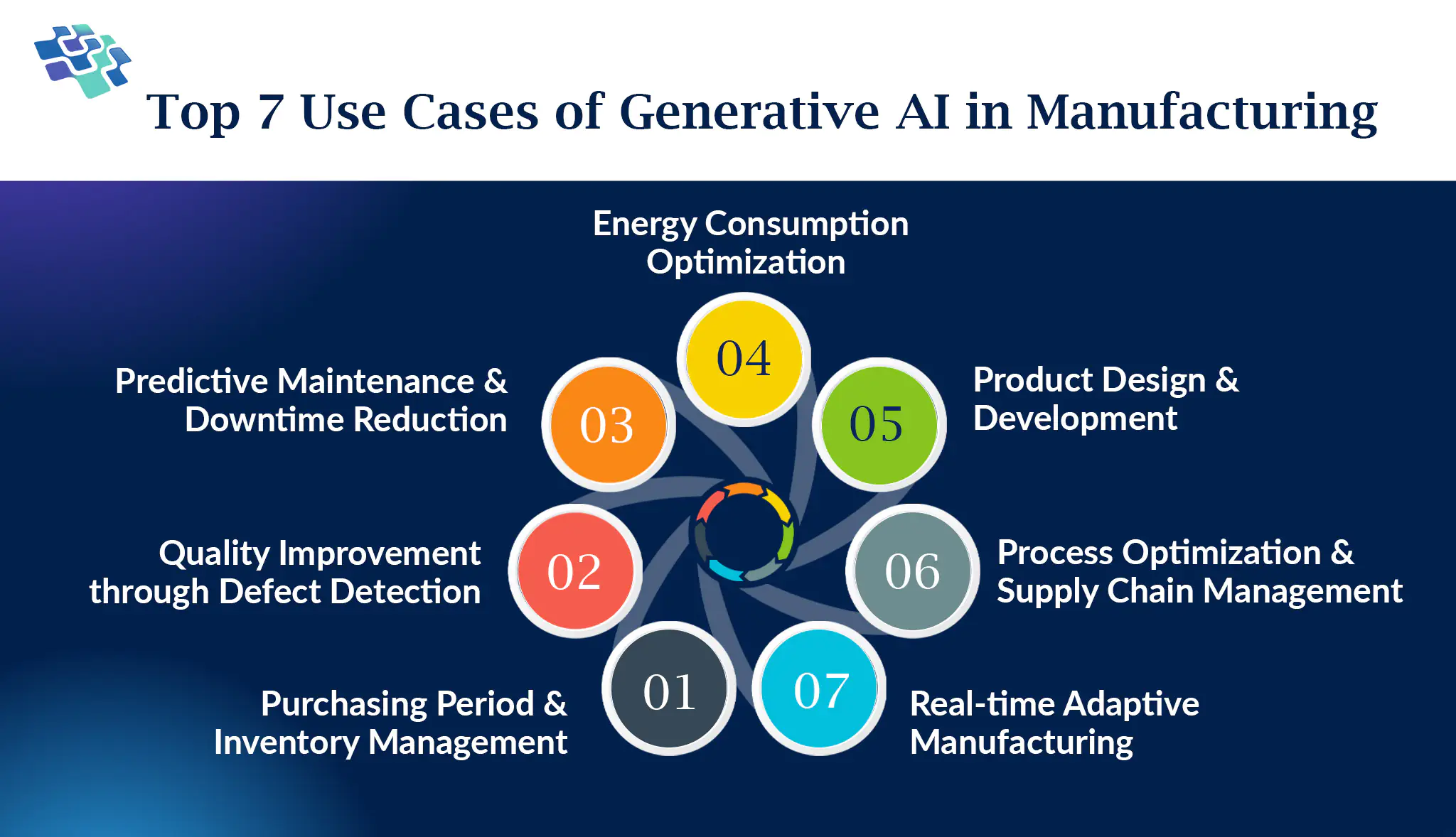

7 Most Important Use Cases of Generative AI in Manufacturing

Consider a scenario in which data is more than just numbers and figures. Rather, it is a dynamic force that molds the fundamental essence of business activities. That is the exact contribution that generative AI in manufacturing makes.

How AI is Reducing Energy Consumption in Manufacturing Industries?

With its ability to foresee energy demand, particularly by anticipating machinery usage and malfunction, AI reduces energy consumption in manufacturing industries and improves process efficiency.

Stay In the Know

Get Latest updates and industry insights every month.

1. AI-Powered Predictive Costing for Instant Quotes

1. AI-Powered Predictive Costing for Instant Quotes