How Artificial Intelligence Is Impacting Supply Chain Management?

AI incorporates advanced mathematical models and adaptable learning systems to develop innovative products and processes that enable organizations to make informed decisions and drive business growth.

In a recent podcast, Deepak Mittal, Founder & CEO of NextGen Invent, and Scott Saunders, the CEO of Saunders Leadership Institute, discussed the significant role of Artificial Intelligence (AI) in supply chain management, as well as the emerging trends that supply chain managers must keep up with.

“Through the integration of AI-powered supply-chain management, adopters have achieved significant improvements in their logistics processes. These enhancements have resulted in a remarkable 15% reduction in logistics costs, a substantial 35% reduction in inventory quantity, and a notable 65% enhancement in service quality.” – McKinsey

As a seasoned professional with more than 30 years of experience in the industry, Scott provided invaluable insights into the topic.

What Exactly Is Supply Chain?

A supply chain is an assortment of organizations that are connected either directly or indirectly and who depend on one another to provide a service or product. It involves the distribution of raw materials to manufacturers, delivery of finished products to distributors, and providing products to the end consumer.

Supply chain management involves planning, organizing, and controlling the flow of goods and services, including Production, Logistics and Distribution. Efficient organizations network management is crucial for delivering products and services to customers on time, at the right location, and at the right price.

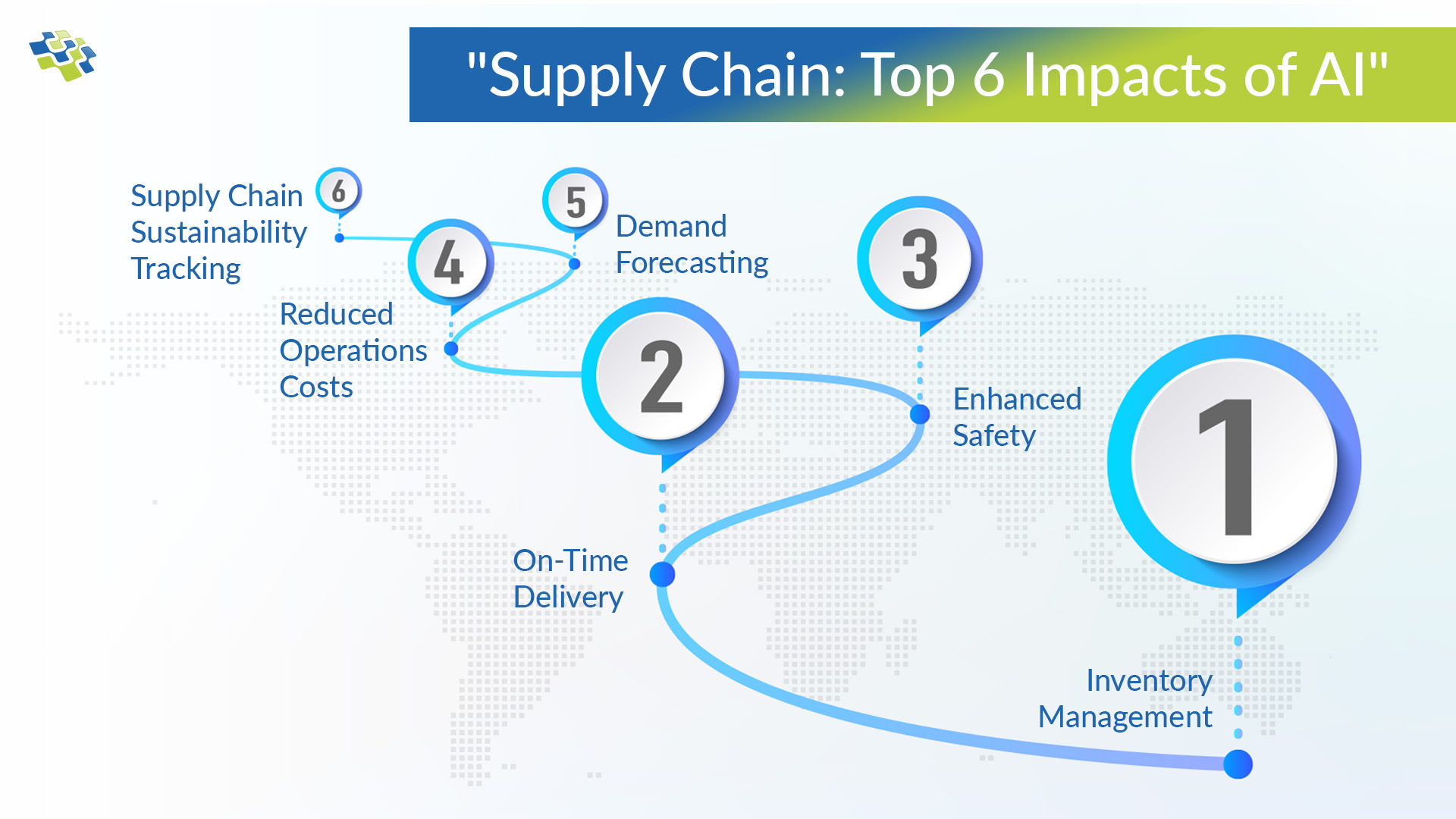

AI in Supply Chain Management: Top 6 Impacts

Discover how you can use AI to drive growth and stay one step ahead of the competition. The following are a few of the main points that discuss the impact of AI in supply chain management:

1. Inventory Management

1. Inventory Management

The abundance of real-time images and data available in today’s inventory management can make it challenging for inventory managers to keep up. However, by leveraging AI, inventory management can become more efficient and effective, with access to innovative solutions.

AI-powered systems can automatically manage the flow of commodities to meet manufacturing demand, ensuring that the right number of raw materials enters and exits the warehouse.

With this technology in place, warehouses are less likely to experience issues such as stock shortages, excess inventory, or improper stock.

2. On-Time Delivery

The integration of artificial intelligence (AI) technology has brought about significant improvements in the speed, safety, and intelligence of supply chain operations. With the help of AI, the need for manual labour has decreased while the delivery process to customers has become more streamlined.

Automated warehousing processes have been accelerated, saving valuable time in the supply chain delivery process.

By leveraging AI, computers can now process information about clients, drivers, and vehicles to create the most efficient routes, resulting in timely deliveries. As a result, businesses can provide customers with a seamless and reliable delivery experience.

3. Enhanced Safety

AI-based automated technologies have the potential to revolutionize warehouse management by enabling better planning and improving the safety of both workers and materials.

By analysing data on workplace safety, AI can identify potential hazards and alert producers of any concerns. This proactive approach allows for quick and effective interventions, minimizing the risk of accidents.

In addition to enhancing safety, AI can also optimize warehouse operations by updating stocking parameters, providing feedback loops, and performing preventative maintenance. These measures ensure that warehouses remain compliant with safety regulations and that potential issues are identified and addressed promptly.

4. Reduced Operations Costs

Automated systems can operate error-free for extended periods, improving the overall safety and reliability of business operations.

In addition, the use of robotics in warehouses can significantly improve productivity. Warehouse robots can operate with greater precision and speed, resulting in faster order fulfilment, reduced lead times, and increased throughput. This improved efficiency translates into lower operational expenses, as businesses can accomplish more in less time, and with fewer resources.

Overall, the implementation of automated intelligent operations and robotics in warehouse management offers a powerful combination of improved safety, reliability, and productivity. By these technologies, businesses can stay competitive, streamline operations, and achieve greater success.

5. Demand Forecasting

AI also has a lot to offer businesses like manufacturers and retailers. These businesses can employ AI data analysis techniques to obtain a precise forecast of supply and demand in upcoming quarters.

To forecast how much of a certain product will be in demand, AI algorithms can examine a variety of data sets, including sales data and customer tendencies. Every stage in the supply chain may ease supply pressure by using precise demand forecasting.

Manufacturers do not need to place excessive orders with raw materials suppliers if they know exactly how much of a given resource they will require. The same holds true for merchants who place orders with manufacturers. In the end, this might also aid in cutting down on waste in the supply chain.

6. Supply Chain Sustainability Tracking

AI offers increased visibility to assist companies in monitoring the sustainability of their supply chains. One example of this is the use of AI logistics algorithms for route optimization, which can help businesses choose the most effective shipping routes on land or at sea, reducing the carbon footprint of their supply chains.

Furthermore, AI algorithms can be used to track the entire supply chain of a finished product, including the origin of each component. This level of transparency and traceability can help businesses identify potential sustainability weak spots in their supply chain, raising awareness and promoting action.

By leveraging AI-powered technologies, businesses can not only reduce waste and improve sustainability but also gain a competitive advantage in the marketplace. Consumers are increasingly demanding eco-friendly products and supply chain practices, and businesses that prioritize sustainability can build brand trust and loyalty.

Conclusion

In today’s data-driven world, artificial intelligence has become an essential tool for supply network management. AI-powered technologies provide businesses with the capability to analyse complex data sets, identify patterns, and make data-driven decisions. With AI, businesses can gain deeper insights into their supply chains, improve forecasting accuracy, optimize inventory management, and streamline logistics operations.

The usage of AI will grow increasingly more common and significant in the future as data becomes more easily accessible and technology develops. Companies will be better positioned to compete in the data-driven business world if they invest in AI and other innovative technology.

At NextGen Invent, we are passionate about leveraging the latest technologies to help businesses achieve their goals. Our AI-powered solutions for supply chain management are no exception. With our services, businesses can gain deeper insights into their supply chains, streamline operations, and improve overall efficiency.

Contact us today to learn how we can help you stay ahead of the curve in the rapidly evolving world of supply chain management.

Key Take Away from Our Podcast:

The need for visibility in the supply chain, from “dirt to dirt,” which involves real-time or near real-time tracking of the flow of goods, transactions, and information across extended networks, including social networks. This information is critical for decision-making and revenue generation, and managers should leverage predictive analytics to anticipate future events.

COVID-19 pandemic has caused unprecedented disruptions in the supply chain, highlighting the need for resilience and agility. Data analytics and AI has immense potential to help supply chain managers in ways never thought before. However, companies must also address the challenges of data quality, cultural barriers, and specialized expertise to fully leverage the benefits of AI in their supply chain management. – <LISTEN TO OUR PODCAST>

Stay In the Know

Get Latest updates and industry insights every month.