10 Most Crucial Use Cases of Generative AI in Supply Chain

Businesses can leverage this AI subset’s power to examine the vast quantity of data entailed in supply chain management. We’ll be talking about some of the key facets of Generative AI in supply chain management in this blog.

Predict Demand Like Never Before! Revolutionize Inventory Management with Our Generative AI Precision!

“Generative AI can help industries by maintaining the supply chain management process by reducing the cost of acquisition and improving customer satisfaction. Generative AI in supply chain minimizes the challenges that come with customer satisfaction, increasing need for sustainable practices, and rapid market fluctuation.”- Precedence Research

Generative AI in Supply Chain: Overview

Generative AI is transforming supply chain management, with 40% of companies investing in its application. Unlike traditional AI, Generative AI analyzes data to uncover new patterns and trends, rather than relying on predefined outputs. It predicts unexpected situations and suggests non-programmed solutions, enhancing decision-making in dynamic environments. Through knowledge management, it generates forecasts, data-driven strategies, and original content. In the supply chain, it models intricate logistics networks and forecasts outcomes for various methods in different scenarios. This advanced technology empowers companies to adapt efficiently, improving operational efficiency and resilience.

Challenges Faced by the Supply Chain Industry

Like anything else, there are advantages and disadvantages to using digital transformation services to incorporate Generative AI into your supply chain system. Understanding these challenges is essential before deciding to integrate Generative AI into the supply chain. It will guide you to a comprehensive understanding of how to approach problems strategically and then engage with the development of Generative AI.

- Data Quality and Availability: Providing high-quality data is the first challenge businesses may encounter when applying Generative AI in supply chain management. For Generative AI algorithms to be trained effectively, enormous volumes of high-quality data are needed. It can be difficult to obtain and keep such data in the supply chain. Models with errors and predictions with inaccuracies might result from incomplete or inaccurate data. Businesses need strong data-collecting and management techniques to get beyond this obstacle. By collaborating with a Generative AI development services company like NextGen Invent, you may take advantage of it.

- Balancing Costs & Sustainability: Supply chain managers are faced with the challenge of maintaining environmental and social responsibility standards while reducing costs and improving operational efficiency. To reduce waste, emissions, and resource consumption and to support social causes and communities, businesses must adopt lean manufacturing, a circular economy, green logistics, and ethical sourcing practices.

- Integration with Existing Systems: Integrating Generative AI into existing supply chain management systems poses challenges due to compatibility issues with legacy hardware and software. Seamless integration is vital to avoid disruptions to ongoing operations, necessitating careful consideration and potential system upgrades or modifications.

How Generative AI Transforms Supply Chain Operations?

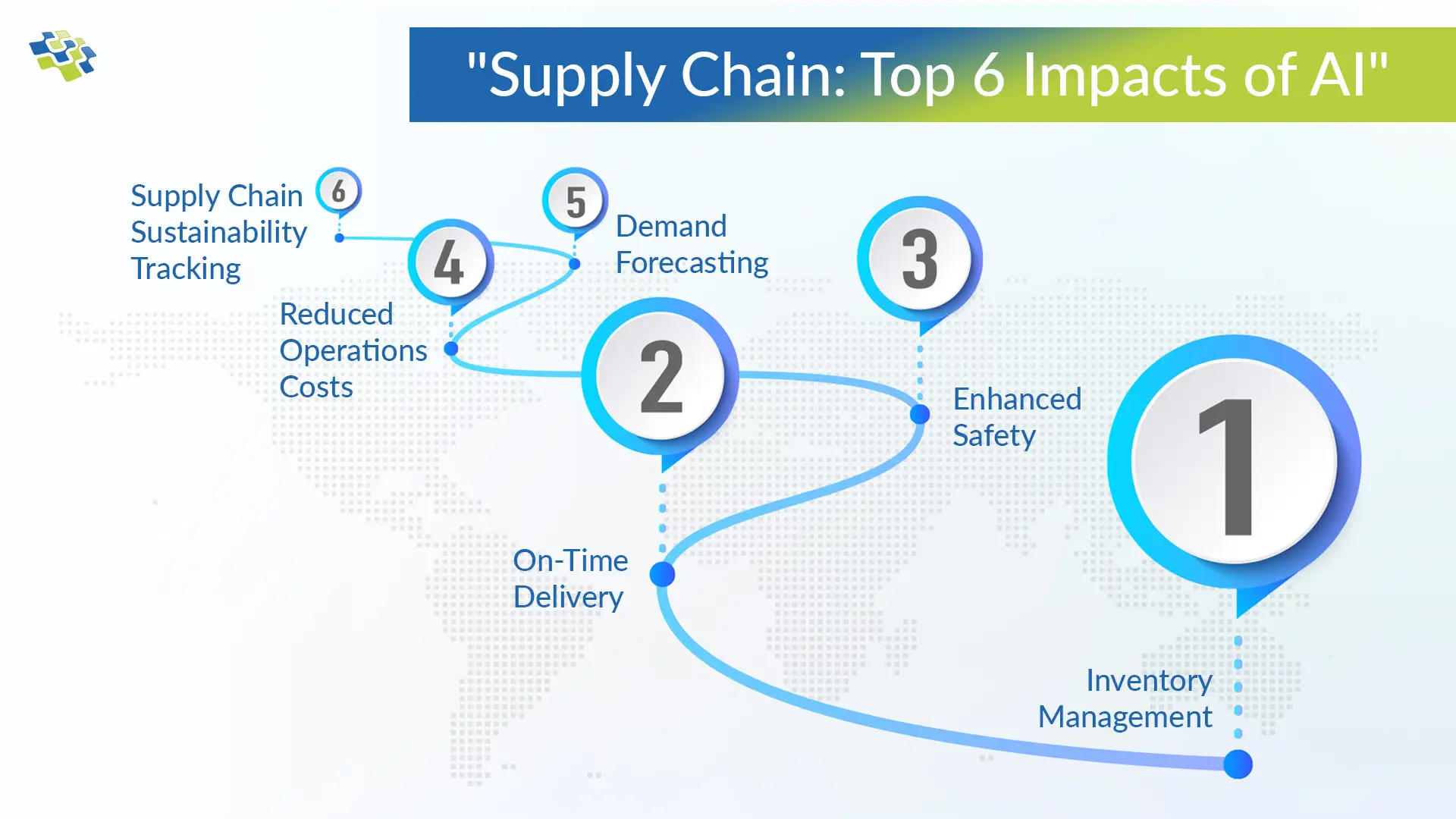

Supply chain operations could be completely changed by Generative AI since it brings levels of efficiency that conventional operations just cannot match. 77% of participants in the poll felt that Generative AI logistics has a significant impact on the supply chain. Businesses can also predict outages with the use of Generative AI in supply chain planning. Early adopters have seen a 15% reduction in logistical expenses and a 35% increase in inventory levels. In comparison to slower-moving competitors, service levels increased by 65% as well.

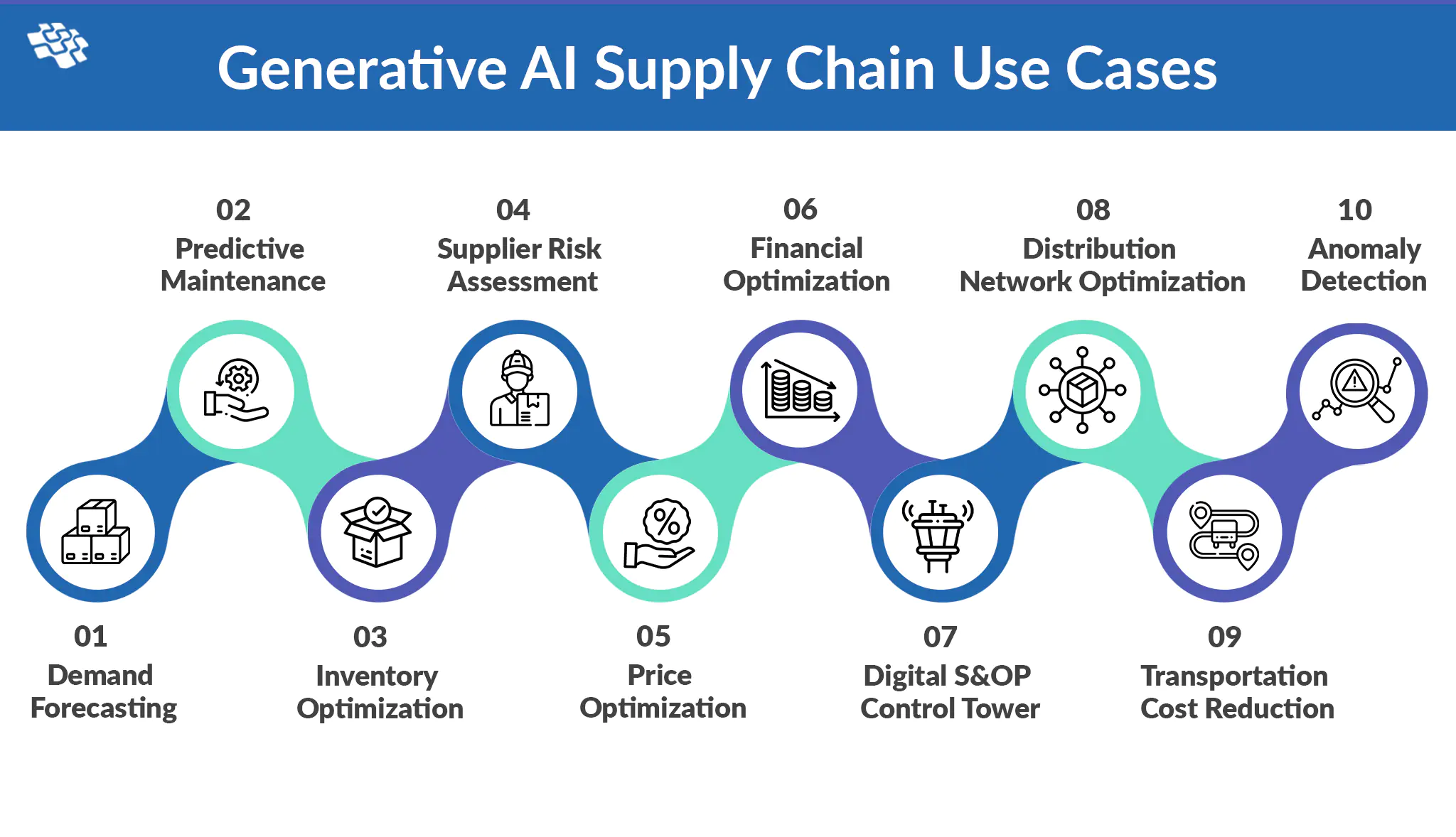

10 Most Crucial Use Cases of Generative AI in Supply Chain

1. Demand Forecasting

1. Demand Forecasting

Generative AI in the supply chain improves inventory optimization, lowers product shortages, and boosts customer happiness by revolutionizing demand forecasting in supply chain management. It increases demand prediction accuracy by applying complex algorithms to historical data, market movements, and outside variables. The strength of generative models resides in their capacity to handle several variables at once, revealing intricate relationships and patterns that conventional forecasting methods frequently miss. A business’s capacity to forecast demand fluctuations, maximize output, and modify inventory levels is enhanced by this accuracy, which leads to increased operational effectiveness and financial gains. Generative AI is most effective when it processes large amounts of previous sales data and considers marketing campaigns, macroeconomic factors, and cyclical shifts. The AI model gains proficiency in producing precise demand estimates as it gains knowledge from this abundance of data. What was the outcome? Businesses can strategically deploy resources, keep an eye on emerging market trends, and expertly control inventory levels.

2. Predictive Maintenance

Supply chain operations can be severely disrupted by equipment failures and unplanned downtime, which frequently results in major financial loss. In this case, Generative AI proves to be an important tool for putting predictive maintenance plans into practice. This is accomplished using information analysis, including sensor data, maintenance records from the past, and equipment performance indicators. Generative AI algorithms that recognize patterns and abnormalities in the data can forecast when maintenance is required. As a result, companies can reduce downtime, extend the life of their equipment, increase operational efficiency, and save maintenance costs by planning for repairs or replacements in advance.

3. Inventory Optimization

The crucial balancing act of inventory management is preventing product shortages while reducing the expenses linked to having too much inventory. Maintaining this equilibrium in the supply chain is made possible by Generative AI, which analyzes past data, demand trends, and external factors to determine the ideal inventory levels. Businesses may avoid overstocking, cut down on excess inventory, and improve supply chain responsiveness with the use of this technology. When considering demand changes, delivery timeframes, and transportation costs, Generative AI models can determine the best distribution and storage techniques. Maximized operational efficiency and significant cost savings are the results. Generative AI helps companies improve warehouse management by suggesting reorder points and safety stock levels, which reduces product shortages, minimizes excess inventory, and lowers holding costs.

4. Supplier Risk Assessment

Generative AI algorithms utilize extensive datasets like news articles, financial reports, and historical supplier performance to discern patterns indicative of potential supplier risks. This empowers companies to evaluate the reliability of their suppliers, anticipate potential challenges, and proactively manage risks. By identifying trends and emerging issues early on, businesses can take decisive action to mitigate disruptions and safeguard their operations. This might involve diversifying their pool of suppliers to spread risk or implementing contingency plans to address foreseeable setbacks. Ultimately, leveraging Generative AI enables organizations to make informed decisions, enhance supply chain resilience, and maintain continuity in the face of uncertainty. It represents a proactive approach to risk management, providing companies with the insights needed to navigate complex supply chain dynamics effectively while optimizing performance and minimizing vulnerability to disruptions.

5. Price Optimization

Generative AI models leverage data on competitor pricing, market conditions, and customer demand to craft optimal pricing strategies for businesses. These strategies are designed to enhance competitiveness while simultaneously maximizing sales, profit margins, and market share. By analyzing a multitude of variables, including the pricing strategies of rivals and the prevailing market conditions, AI can provide valuable insights to companies seeking to navigate dynamic market landscapes. Through the utilization of Generative AI, companies can gain a deeper understanding of consumer behavior and market trends, allowing for more informed decision-making in pricing strategies. This enables businesses to adapt quickly to changes in market demand and competitor actions, thereby maintaining a competitive edge.

6. Financial Optimization in Supply Chain

The utilization of Generative AI in financial services and operations has noteworthy benefits for supply chain management through increased productivity, reduced risk, and improved decision-making processes. Using Generative AI in the financial components of the supply chain can address several issues:

- Fraud Detection & Mitigation: Generative AI algorithms examine transaction data, spot trends, and abnormalities, and highlight possible supply chain fraud cases. This capability helps companies to maintain the integrity of their supply chain processes, prevent financial losses, and protect their brand.

- Risk Management: Generative AI can be used to evaluate a wide range of risks, including changes in interest rates, currency fluctuations, and geopolitical events. Artificial intelligence can help firms build ways to reduce these risks by producing insightful data. This promotes stability and effective financial risk management among supply chain participants.

7. Digital S&OP Control Tower

A digital Sales and Operations Planning (S&OP) control tower provides instant insights into inventory, demand, and production, streamlining supply chain management and global logistics. Data analytics, enables informed decision-making to prevent stockouts and backorders, leading to smoother operations. By optimizing inventory levels and reducing backorders, companies can achieve a more agile and efficient S&OP process, ultimately boosting overall performance. This centralized platform enhances visibility across the supply chain, allowing stakeholders to react promptly to changes and allocate resources effectively. With real-time data at their fingertips, businesses can proactively address issues, minimize disruptions, and capitalize on opportunities, ensuring sustained growth and customer satisfaction. In essence, the S&OP control tower acts as a strategic tool, empowering organizations to align their resources with market demand, improve operational efficiency, and drive competitive advantage in today’s dynamic business landscape.

8. Distribution Network Optimization

Leveraging Generative AI to optimize distribution networks strategically reduces logistical expenses for businesses. By analyzing data, businesses can identify efficient transportation routes, optimal warehouse locations, and demand trends, maximizing the movement of goods. This approach enhances supply chain flexibility, lowers transportation costs, and improves operational effectiveness. Through the strategic use of analytics, companies can make informed decisions regarding inventory placement and transportation routes, leading to streamlined operations and reduced expenses. Additionally, by adapting to changing demand patterns and market dynamics, organizations can further enhance their distribution efficiency. This holistic approach to distribution optimization results in significant cost savings for businesses. It allows businesses to allocate resources more efficiently, minimize unnecessary transportation expenses, and improve overall supply chain performance.

9. AI-Based Transportation Cost Reduction

Utilizing Generative AI in supply chain services involves leveraging real-time data analysis to optimize routes, thereby reducing transportation costs significantly. Through sophisticated algorithms, AI considers various factors like traffic patterns, delivery schedules, and fuel efficiency to ensure the most efficient and cost-effective transportation possible. This strategic approach results in substantial savings by streamlining logistics operations, reducing fuel consumption, and minimizing overall operating expenses. By dynamically adjusting routes based on current conditions and predictive analytics, companies can maximize efficiency while minimizing unnecessary expenses. The implementation of AI-driven route optimization not only enhances cost-effectiveness but also improves the reliability and timeliness of deliveries. This, in turn, boosts customer satisfaction and strengthens relationships with partners and clients.

10. Anomaly Detection

Generative AI models scrutinize data across diverse supply chain elements, pinpointing irregular trends or deviations from norms. This analytical prowess enables early detection of issues such as bottlenecks, quality lapses, or sudden fluctuations in demand. By identifying these anomalies promptly, organizations can take preemptive action to mitigate risks and prevent the exacerbation of problems. This proactive stance is pivotal in maintaining operational fluidity and averting potential disruptions. Through the foresight provided by Generative AI, businesses can address challenges swiftly and efficiently. They can allocate resources effectively, optimize processes, and ensure timely responses to evolving circumstances.

Things Businesses Should Ask Before Using Generative AI in Operations

Supply networks overflowing with data may find that artificial intelligence changes everything. To automate boring, repetitive tasks and equip tomorrow’s workforce with the necessary knowledge, forecasts, and recommendations, the difficulty is to integrate this data into the business context of the job function or task at hand. Three categories are necessary for businesses to divide their Generative AI initiatives into:

- Enhance current operations for quicker and more efficient execution.

- Enhance the user interface for easier navigation and contextual guidance.

- Introduce novel processes and innovations previously absent within the organization.

Why Trust NextGen Invent for Generative AI Development Services?

Having gained a comprehensive understanding of Generative AI’s pivotal role in supply chain operations, businesses are poised to leverage its transformative potential optimal growth. However, ensuring seamless alignment with business objectives necessitates expert guidance. NextGen Invent offers specialized Generative AI development services tailored to your needs. Our seasoned professionals possess extensive experience in implementing Generative AI in supply chain domains. Whether integrating with existing systems or developing bespoke Gen AI solutions, we deliver results aligned with your business goals. Enhance your supply chain efficiency and innovation with NextGen Invent’s expertise in Generative AI development.

Contact us now to unlock the full potential of AI-driven solutions for your business and to explore our Generative AI in supply chain management software development services.

Related Blogs

How AI Is Impacting Supply Chain Management?

Industry experts are certain that AI in supply chain management will “change the game”. It is rapidly emerging as a transformative technology, with the ability to process vast amounts of operational data generated by a range of sources, including cloud-based applications and sensors.

How Can AI Transform Your Retail Business?

To stay competitive in the current global economy, retail enterprises must put profit and productivity first. To be successful and keep a step ahead of the competition, rapid and effective action is required. AI in retail can enhance operations, boosting revenues and streamlining workflows.

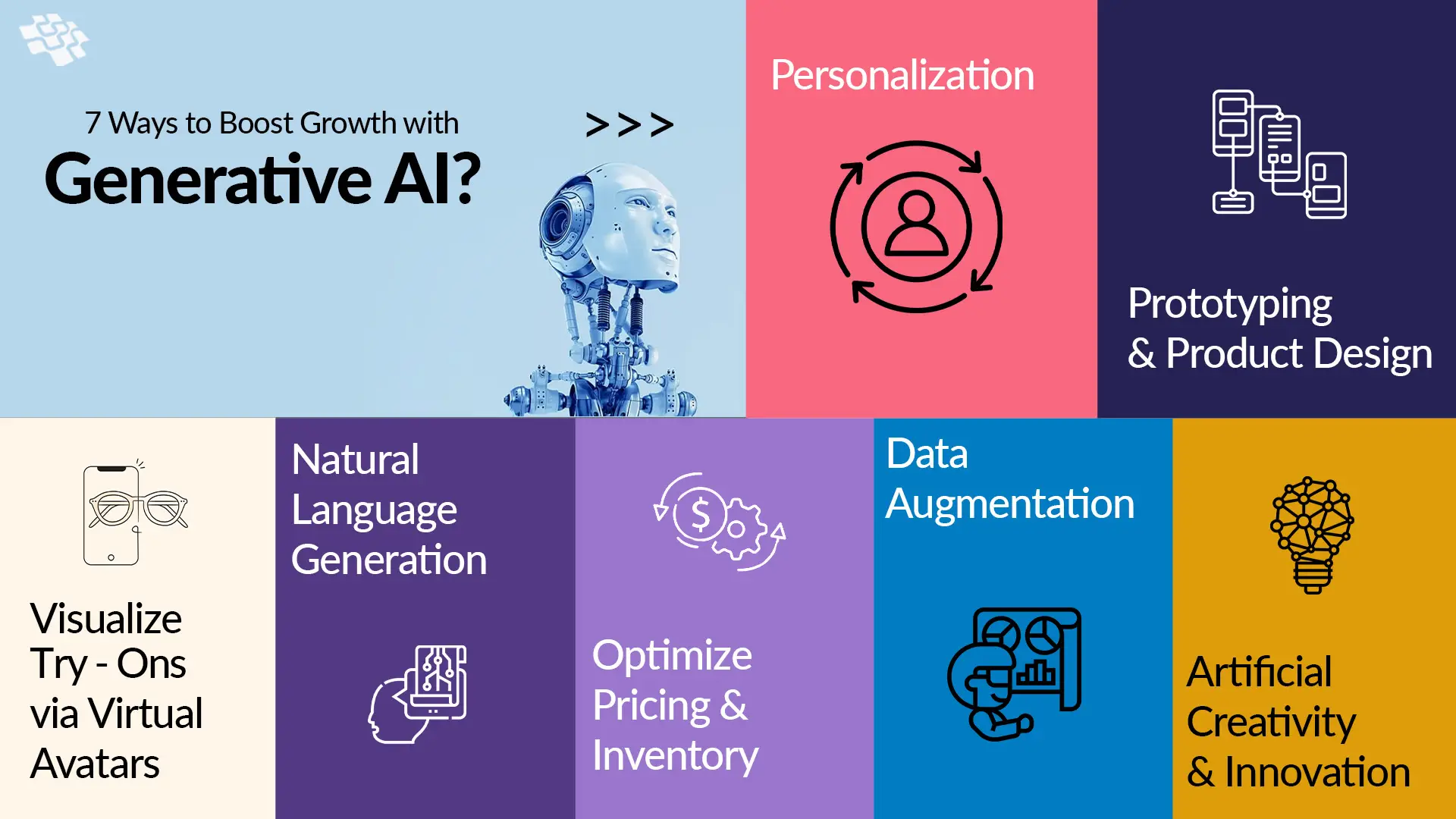

7 Ways to Boost Growth with Gen AI for Business

For many corporations, Generative AI (Gen AI) has evolved from a futuristic notion to an integral part of their day-to-day operations. Remarkably, a recent poll discovered that 91% of leading companies actively invest in Gen AI, fully acknowledging its indispensable role in driving innovation and efficiency.

Stay In the Know

Get Latest updates and industry insights every month.

1. Demand Forecasting

1. Demand Forecasting