Importance and Use Cases of Big Data in Manufacturing

Why is big data in manufacturing important? How can the manufacturing industry fully utilize big data? These and a few more questions have been sought to be addressed. Prominent producers employ Big Data to examine the movement of completed items and enhance their ability to react to signals of demand.

Struggling with Predictive Maintenance? Learn How Our Big Data Tools Reduce Downtime and Improve Performance

“The big data era has only just emerged, but the practice of advanced analytics is grounded in years of mathematical research and scientific application. It can be a critical tool for realizing improvements in yield, particularly in any manufacturing environment in which process complexity, process variability, and capacity restraints are present.”– Mckinsey

Overview of Big Data in Manufacturing Industry

The term “big data” in manufacturing refers to the vast and intricate datasets that can aid in decision-making, provide producers with new perspectives, and reveal trends in the manufacturing sector. Big data gathers information from many sources, including:

- Equipment sensors,

- Supply chain logistics,

- Customer feedback, and more.

Big Data’s primary attributes in production are veracity, value, volume, velocity, and variety. Big data in the manufacturing industry can be used to track production, anticipate machine breakdowns, analyze sales data from the past, track market trends, and more.

Why is Big Data in Manufacturing Important?

Big data is essential to the manufacturing industry because it offers superior insights at every step of the process, including data from devices, equipment, and workers. Big data in the manufacturing industry is used to:

- Lower costs,

- Improve product quality,

- Streamline their supply chain, and

- Obtain insightful knowledge.

In addition, big data may help manufacturers by anticipating maintenance requirements, minimizing downtime, and establishing a secure and safe work environment.

Importance of Big Data in Manufacturing: Overview

The manufacturing sector has been impacted by big data. Now let’s examine some instances of big data in manufacturing:

- Quality Check: Real-time monitoring and identification of the production process is another application for big data. In this manner, any flaws or departures from the quality requirements can be inspected by the makers. In this manner, producers can monitor the equipment’s quality and minimize flaws by implementing remedial measures.

- Demand Forecasting: Big data can be used to examine past sales data, marketing trends, and other prospective product requests. This can be quite helpful for understanding client requests and modifying production levels. By creating items that cater to consumers’ interests, manufacturers can increase sales by getting a deeper understanding of their clientele.

- Supply Chain Optimization: Manufacturers can quickly discover and process the data along the supply chain to improve inventory levels. This aids producers in cutting lead times and enhancing the effectiveness of the supply chain. Enhancing client happiness while cutting expenses concurrently.

Refer to Our Podcast for Further Details:

Weathering the Storm- Why Supply Chain Resilience is Always in Season

Leverage Predictive Analytics to Minimize Downtime and Boost Output

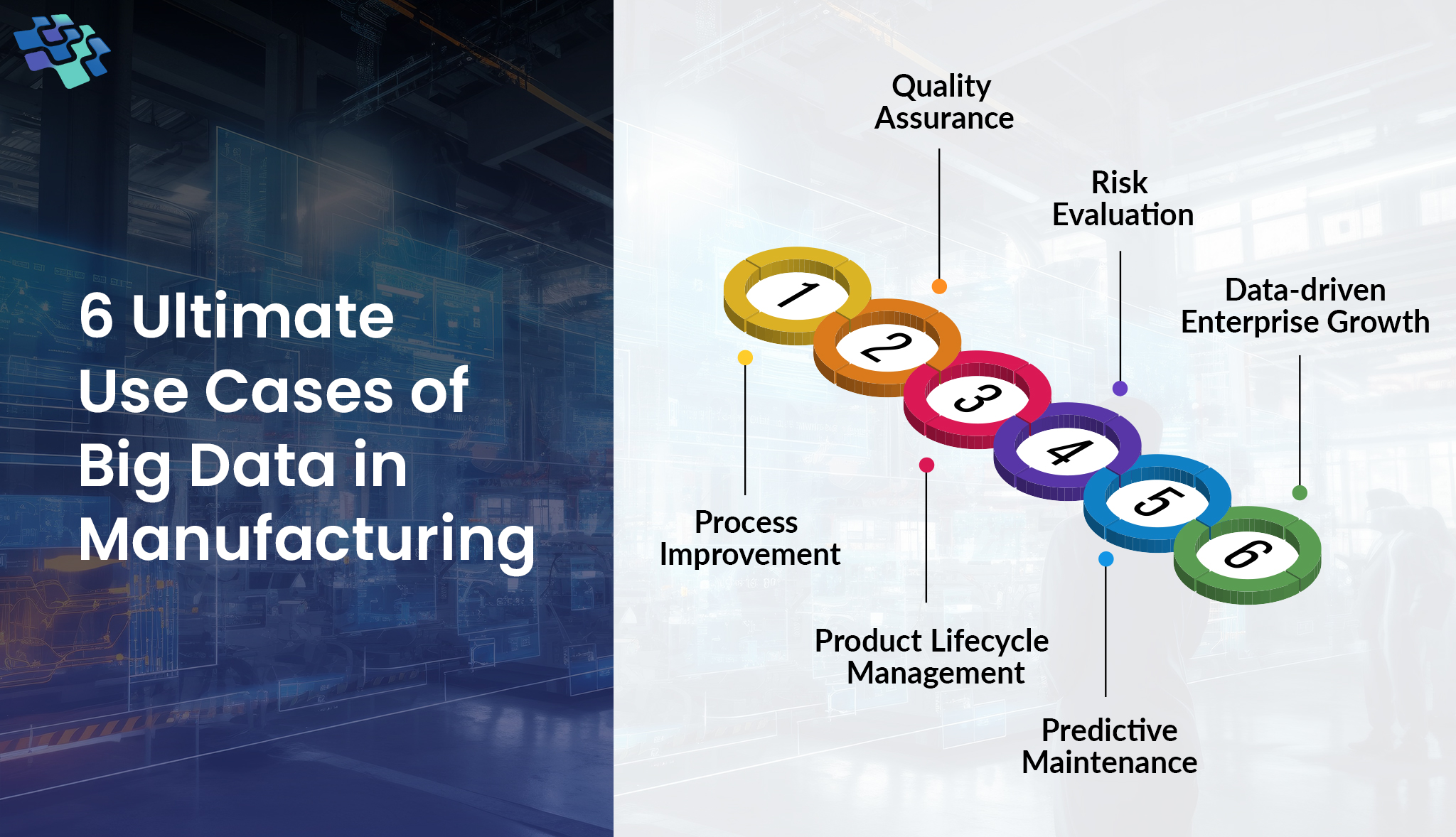

Use Cases of Big Data in Manufacturing

There are many more big data applications in production settings as a result of the sheer amount of information found in big data and the advancements made in data science. The following examines some of the applications of big data that manufacturers are utilizing to facilitate ongoing development, such as:

1. Process Improvement

1. Process Improvement

Manufacturers can reduce unexpected downtime by using big data in conjunction with IoT sensors implanted in production equipment to adopt a more proactive approach to maintenance. IoT sensor data, for instance, can be integrated with information from other data sources, including maintenance, operational history, and environmental factors. Following that, this data can be used with advanced data analytics and machine learning to:

- Identify the type of maintenance that is required.

- Determine the primary cause of equipment malfunctions to expedite the resolution of issues.

- Estimate the equipment’s usable life.

- Choose the optimal time for maintenance depending on the state of the equipment, not on a set timetable or in response to issues.

- Determine when an equipment component is most likely to fail.

2. Quality Assurance

A subtype of computer vision termed machine vision is mostly used in the manufacturing industry. There is a lot of overlap between these two solutions. Machine vision algorithms are built on cameras and sensors, just like computer vision algorithms are. However, the technology used in machine vision is specifically designed to meet the demands of the production industry. The use of it in quality assurance and control is common. For instance, the following are possible with machine vision algorithms:

- Identifying variations and issues with the completed product

- Analyzing a large amount of visual data at once

Quality assurance is improved and becomes more precise as a result. You can also reduce the number of employees involved in this aspect of your daily work with this solution. Furthermore, other big data-related technologies like machine learning and deep learning usually support quality assurance.

3. Product Lifecycle Management

PLM, in general, refers to managing a product at every phase of its existence. PLM mostly pertains to the creation and manufacturing of your product, and this is where manufacturing plays a crucial role. Business decisions, such as those about expansion or cost-cutting, pricing, and advertising, are informed by the concept of the product life cycle.

Big data in manufacturing enables you to optimize every component of your product, improving its PLM overall. Companies that manufacture goods also consider information about their past offerings, which helps them improve on their current products.

4. Risk Evaluation

Manufacturing businesses include inherent hazards, which might manifest as either significant losses and narrow profit margins or as casualties. By evaluating and anticipating these dangers, big data can assist in taking preventive action against them. Predicting the elements that influence a product’s sale in the market after it is manufactured can also be aided by this. For instance, production levels can be raised in response to effective product marketing campaigns as demand increases.

If the older data is properly interpreted, it can provide clear insights into the earliest problems that impeded the business’s growth and allow for the early eradication of such concerns.

5. Predictive Maintenance

Additionally, big data can assist manufacturers in anticipating when maintenance is required to prevent malfunctions and downtime. Manufacturers can forecast when maintenance is required by tracking equipment and gathering data from multiple sensors and sources. They can recognize trends and patterns by doing this. With predictive maintenance utilizing big data analytics in manufacturing market, manufacturers can save downtime, prolong the lifespan of their equipment, and avoid expensive repairs—all in contrast to traditional maintenance approaches that depend on set timetables or waiting for faults to occur.

Manufacturers may improve their maintenance schedules and minimize production process disruption by implementing insights from big data analytics. This allows maintenance tasks to be done at the appropriate time. Big data analytics-based predictive maintenance can help manufacturers boost equipment uptime, increase efficiency, and save money and time—all of which will improve business outcomes.

6. Data-driven Enterprise Growth

Businesses can address global development issues by developing new factories in new areas or moving operations to other nations by utilizing big data analytics in the manufacturing sector. By creating prediction models and what-if scenarios, companies can use their historical and external data analysis to determine whether it is still economical to operate factories at their current locations or scale.

Furthermore, when used properly, big data can open up previously undiscovered opportunities, like developing new goods or even breaking into untapped markets.

Optimize Manufacturing Processes and Maximize Productivity with Our Big Data Solutions

Without Big Data, What Could Be Industry 4.0?

The complexity and interconnectivity of modern factories are growing, posing unfamiliar problems that automation powered by big data may solve. Intelligent factories have been able to achieve notable improvements in terms of:

- uptime,

- production speed, and

- error reduction

by leveraging the vast amounts of data generated by IoT and current computer systems. Large and intricate information networks have been made possible by the IoT’s connectivity potential.

For 4.0 technologies to learn, provide predictive analysis patterns, and function so precisely and independently, they would not have been able to interpret and extract value from all that data without big data.

Big Data Analytics in Manufacturing: Who is Using It?

Companies that use big data analytics for manufacturing include those in the oil and gas industry, refineries, chemical production, automotive, plastics, metal forming, and food and beverage manufacturing. The list is endless and even extends outside the manufacturing industry. Analytics is a tool that everyone may use to make data-driven decisions. The most successful use of big data analytics in manufacturing is integrating all their systems to gain a comprehensive understanding of plant performance.

Consider big data analytics as the bonding agent that holds everything together. Analytical tools enable you to understand how and why your processes operate the way they do; without them, key discoveries would remain hidden. To ascertain the growth trajectory of enterprises, including your own, big data analytics is vital. If leveraged properly, the advantages of big data analytics in manufacturing industry can significantly impact a company’s ability to expand.

Meet Your Goals with NextGen Invent’s Big Data Services in Manufacturing

As we’ve discussed throughout the article, big data in the manufacturing industry is the key to high production efficiency, improved anomaly prediction, and competitive advantage. One of the most important business strategies for manufacturing companies nowadays is big data integration. To increase productivity and reduce downtime, they rely on data science use cases. It is neither simple nor sufficient to apply in the conventional systems, nevertheless. Big data must relate to technologies like IoT and AI to fully benefit from the technology.

For manufacturers to fully benefit from this technology, they require NextGen Invent, a leading data analytics services company. Businesses looking for specialized, scalable, and business-focused big data solutions can reach out to us at NextGen Invent for assistance. Our portfolio displays the development of 100+ software solutions, 500+ AI models, 550+ projects completed, and a wide range of industries we have worked in, including manufacturing, supply chain, digital healthcare, eCommerce, finance, and retail.

Contact us if you want to update your manufacturing business with the power of big data.

Frequently Asked Questions About Big Data in Manufacturing

Related Blogs

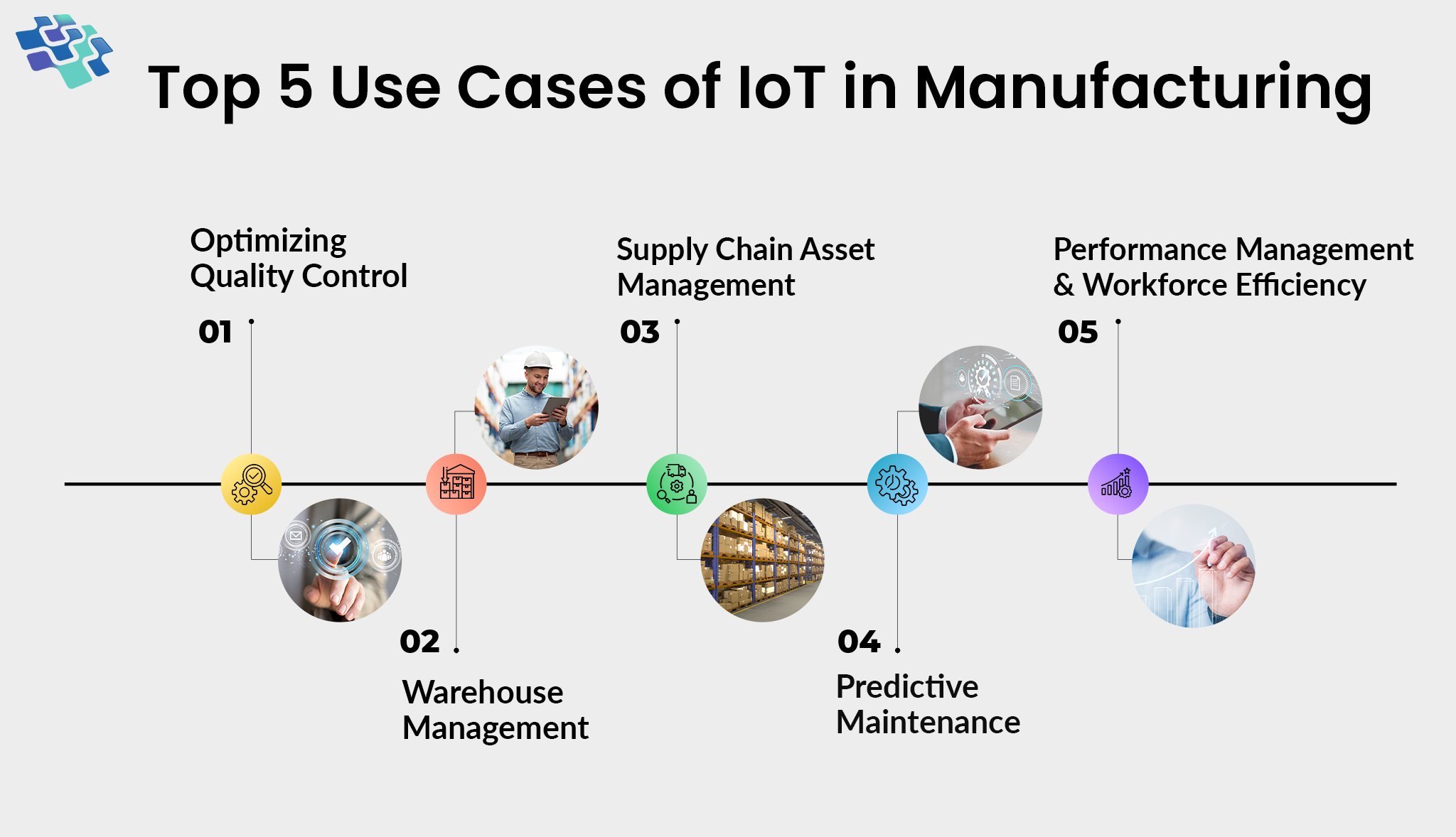

How IoT in Manufacturing is Revolutionizing the Industry

The way industries use data, interact, and function has changed as a result of IoT. In fact, according to a survey of executives in the manufacturing industry, 86% of them thought that smart factory projects would propel the industry during the next five years.

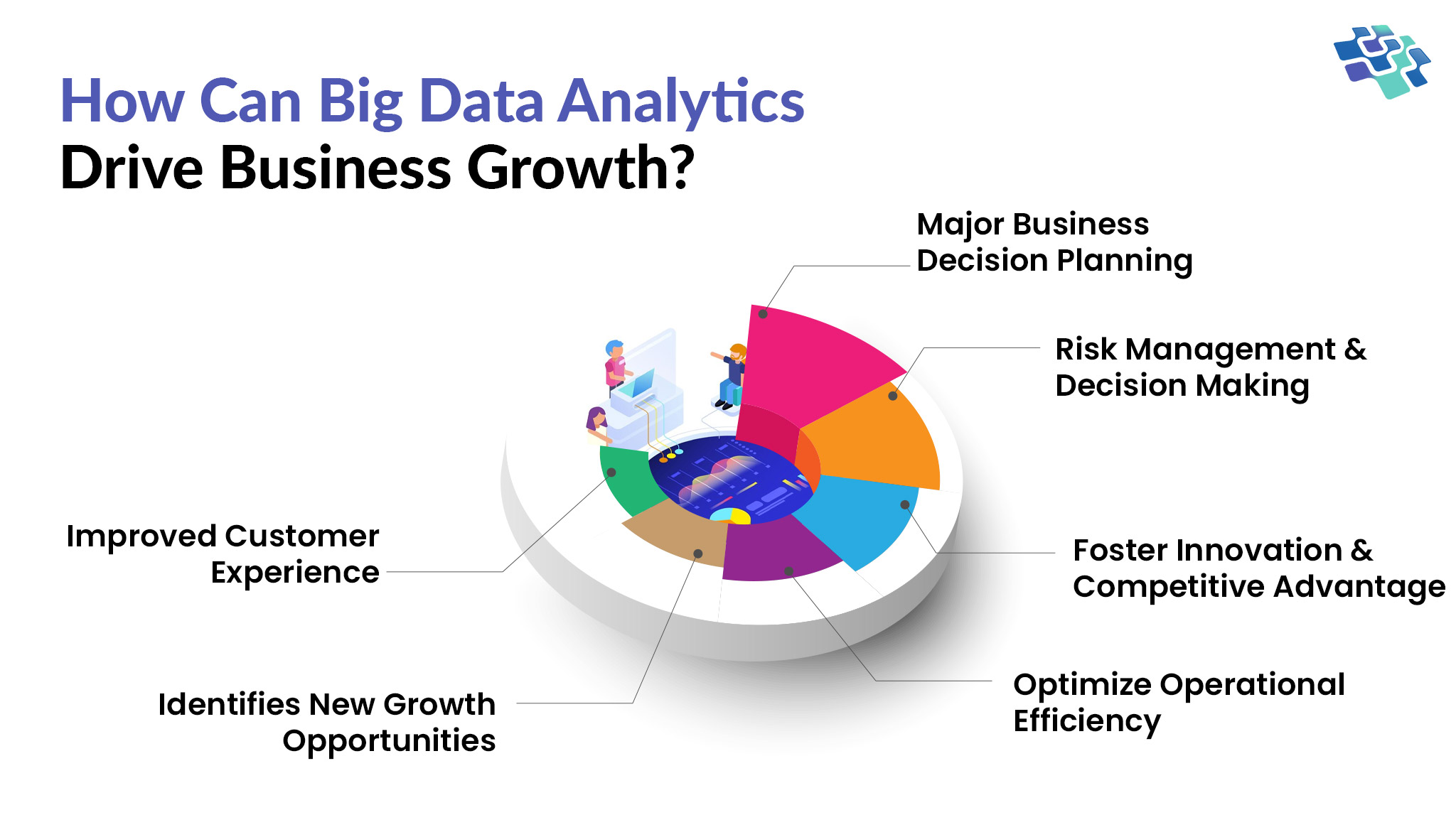

How is Big Data Analytics in Business Driving Growth?

Businesses are gathering enormous amounts of data in today’s ever-changing business environment. They have access to a multitude of data, ranging from website traffic and social media marketing to consumer contact and sales information.

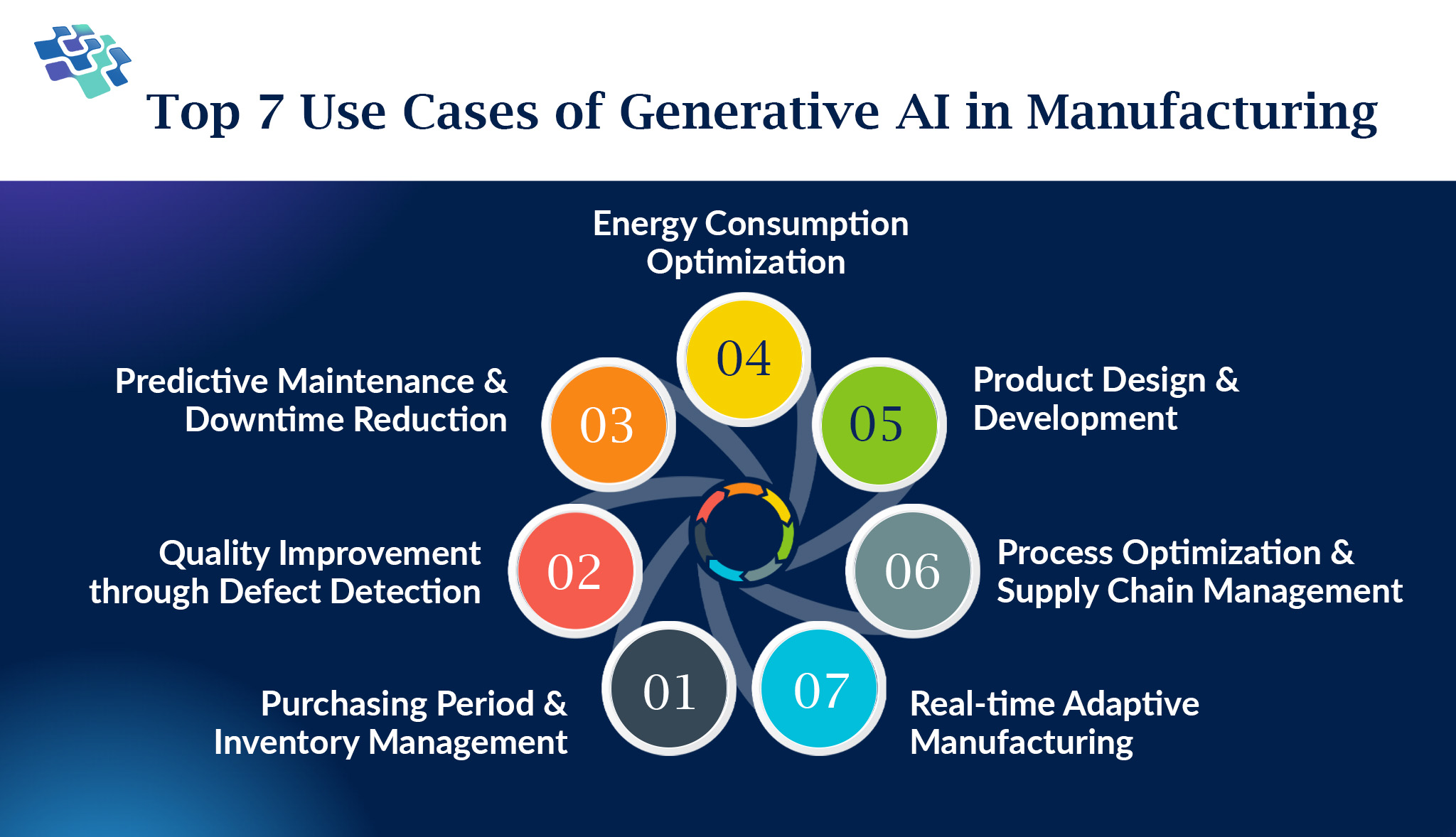

Use Cases of Generative AI in Manufacturing

Consider a scenario in which data is more than just numbers and figures. Rather, it is a dynamic force that molds the fundamental essence of business activities. That is the exact contribution that generative AI in manufacturing makes.

Stay In the Know

Get Latest updates and industry insights every month.

1. Process Improvement

1. Process Improvement