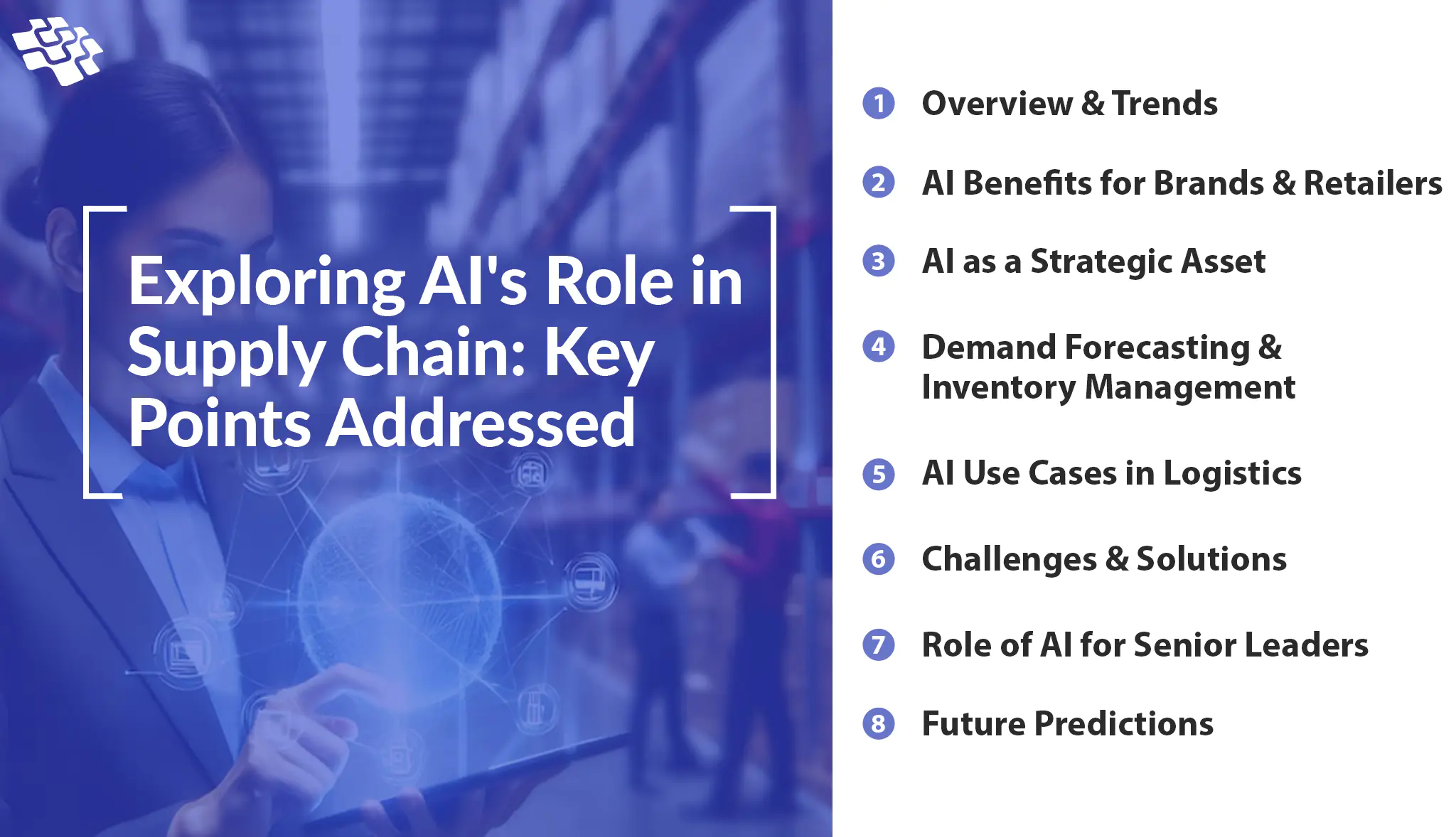

How Agentic AI in Supply Chain Is Powering the Next Big Revolution—and Why It Should Matter to You

It enables non-technical users to engage with complex systems using natural language and obtain not only insights but also autonomous action, thereby making complex capabilities available to all members of the supply chain ecosystem.

Reduce Inventory Delays & Errors While Improving Accuracy and Efficiency Across Your Supply Chain Operations

“To scale impact in the agentic era, organizations must reset their AI transformation approaches from scattered initiatives to strategic programs; from use cases to business processes; from siloed AI teams to cross-functional transformation squads; and from experimentation to industrialized, scalable delivery.”- McKinsey

Agentic Process Automation: Evolution of AI in Supply Chain

The innovative method of agentic process automation goes beyond conventional automation. By allowing AI agents to function independently across various supply chain platforms and providers, agentic process automation eliminates silos that have traditionally reduced productivity.

Agentic process automation helps organizations move beyond limited supported automation, where only 20–30% of processes are automated. It enables fully autonomous supply chain operations, increasing automation to over 50% while enhancing efficiency, adaptability, and decision-making.

The Shift of Agentic AI in Supply Chain: From Analytics to Autonomy

Supply chains have long used predictive analytics to manage inventory, optimize routes, and estimate demand. The future of intelligent systems lies in agentic AI. It takes action in addition to analysis. These sentient beings are not merely tools for making decisions; they are individuals with their own unique perspectives. They are made to operate, cooperate, and adjust in a variety of intricate supply chain settings.

Agentic AI systems are capable of ingesting data from several sources, assessing risk, choosing remedial measures, and initiating those measures on their own, unlike legacy models that rely on human intervention to carry out the following stages. The true revolution is this shift from prediction to realization, from insight to action.

Challenges Addressed by Agentic AI in Supply Chain

Several issues that manufacturers face are resolved by incorporating agentic AI in supply chain operations:

- Complexity of Global Supply Chains: The complexities of international logistics networks are frequently too much for traditional supply chain management to handle. By offering real-time statistics that improve decision-making, agentic AI streamlines this complexity.

- Risk Management: Through advanced analytics to forecast disruptions, agentic AI enables manufacturers to put backup plans into place before problems get out of hand.

- Resource Optimization: By autonomously adjusting production schedules and inventory levels in response to real-time data, agentic AI assists manufacturers in reducing excess inventory and averting stockouts.

- Synergies of Predictive & Prescriptive Analytics: Strong prescriptive and predictive models work best with agentic AI. By providing insights, these analytics produce the organized data AI bots require to behave sensibly.

- Tariff-Aware Resource Efficiency: Agentic AI mitigates tariff impacts by dynamically sourcing alternative suppliers, optimizing routes, and identifying cost-efficient resources to ensure supply chain resilience and efficiency. Check our Podcast on: Tariffs, Trade & Technology – Preparing for Uncertainty in the Supply Chain with AI

The Strategic Benefits of Agentic AI in Supply Chain

1. Self-Healing Training Capabilities

Agentic AI agents can recognize and assess the impact of unforeseen events, such as labor strikes, weather delays, or shortages of raw materials, and quickly reroute shipments, modify timetables, or switch suppliers.

43% of businesses using AI-enabled logistics saw a 40% decrease in downtime by adopting self-healing systems, per a 2023 survey.

2. Real-Time Intelligent Decision-Making

Agents utilize real-time data from:

- TMS and ERP platforms

- Supplier networks

- Inventory systems

They don’t hold out for human evaluation. Rather, they take prompt action to close exceptions and take advantage of possibilities.

According to Gartner, companies that use real-time agentic AI in their supply chain systems see a 22% increase in order accuracy and a 25% speedup in exception management.

3. Increased Predictive Precision

Agentic AI delivers highly accurate forecasts of future demand and inventory needs by analyzing historical trends and comparing them with real-time data, enabling smarter planning and more resilient supply chain operations. It’s especially useful for anticipating sudden shifts and making plans for demand during certain seasons. Businesses may more accurately foresee changes in demand because of their predictive accuracy, reducing the possibility of stockouts or overstocking.

It helps logistics organizations maintain a smooth flow of goods by optimizing stock levels and reducing the need for expensive last-minute shipments or storage overflow fees.

4. Increased Effectiveness & Financial Savings

Efficiency and cost-effectiveness are crucial in logistics because of the small margins. Agentic AI in supply chain learns and adapts to operational demands, streamlining a range of processes from route planning to inventory management.

It can forecast the most fuel-efficient routes or dynamically distribute resources based on current demand, for example, to cut down on unnecessary fuel usage and labor hours. Due to the significant cost savings that follow, logistical operations are streamlined, allowing companies to either reinvest in growing their services or pass savings along to customers.

Prevent Stockouts & Optimize Inventory Management in Supply Chain Management Using Our Intelligent Software Solutions

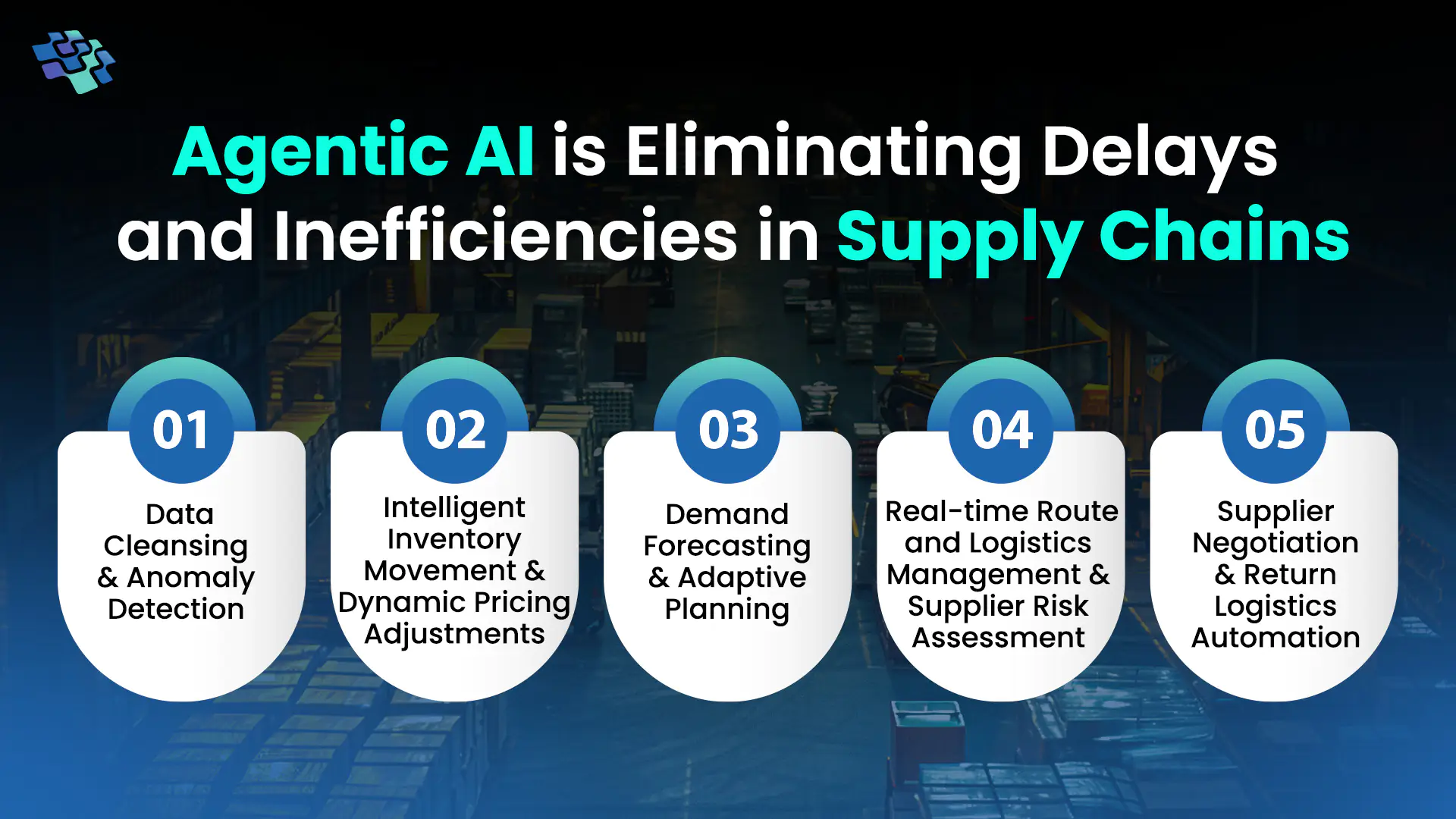

How Agentic AI in Supply Chain Is Tackling Disruptions, Delays, and Inefficiencies, and Powering the Next Revolution

Agentic AI is transforming supply chains by addressing disruptions, delays, and inefficiencies through autonomous decision-making, adaptive planning, and real-time optimization. It empowers resilience, cost efficiency, and agility. Below are the top 5 use cases where Agentic AI is powering the next supply chain revolution.

1. Data Cleansing & Anomaly Detection

1. Data Cleansing & Anomaly Detection

Agentic AI can clean and prepare input data on its own. In sales, pricing, and inventory data, agents can identify and correct errors, outliers, and discrepancies.

- Format Standardization: Make sure that data formats are the same across various systems and sources.

- Missing Data Handling: Use machine learning algorithms or statistical techniques to fill in the gaps left by missing values.

Using a variety of methods, agentic AI can spot odd trends or outliers in price, inventory, and sales history data.

- Statistical Methods: Probability distributions can be used to simulate expected behavior and identify notable deviations.

- Machine Learning Algorithms: Without labeled data, patterns and anomalies can be found using unsupervised learning approaches.

2. Intelligent Inventory Movement & Dynamic Pricing Adjustments

Agents will assess stock levels in various locations and recommend the best inventory movements to rectify stock imbalances. For instance, the agent may suggest moving inventory from another location with extra stock if a specific item is becoming out of stock at one store. This proactive strategy will support the network’s continuous product availability.

When demand and inventory levels change, agents will be able to independently modify their pricing methods. For example, to boost sales and avoid surplus inventory, the agent may recommend temporary price reductions for overstocked items.

3. Demand Forecasting & Adaptive Planning

Through constant observation of competitor activity, market signals, and social trends, agentic AI systems can modify projections in real-time, surpassing the limitations of static predictions.

These intelligent agents drive dynamic supply planning by automatically adjusting production schedules and redistributing inventory across the network, ensuring rapid, data-driven responses to unexpected changes in demand.

4. Real-time Route and Logistics Management & Supplier Risk Assessment

By combining real-time data from many sources and collaborating with warehouse operations, logistics agents optimize delivery routes. They sustain service levels in the face of erratic circumstances by dynamically rerouting fleets and adjusting priorities when disruptions arise, without waiting for human intervention.

To spot interruptions, risk management agents keep an eye on international supply networks and examine news, financial data, and geopolitical developments. When they identify increased danger, they automatically start backup plans, change orders, or modify safety stockpiles to safeguard operations.

5. Supplier Negotiation & Return Logistics Automation

Nobody wants to waste time haggling over little details. However, the cost of those little things can add up. For tactical expenditures like gloves, packaging, and cables, agentic AI in supply chain can track past pricing, volumes, and supplier behavior to negotiate better prices. By offering thorough data on pricing patterns and supplier performance, MIT really highlights how generative AI may improve supplier negotiations and facilitate better decision-making.

Returns are inconvenient. However, manual labor is not required.

Agentic AI can schedule pickups, manage return authorizations, monitor asset status, and make cost-effective decisions on whether to refill, repair, or dispose. An analysis of AI’s application in e-commerce reverse logistics, with a particular emphasis on how it might simplify returns processing and maximize resource allocation, was published in the International Journal of Sustainable Agriculture.

Eliminate Manual Process Bottlenecks and Enable Faster, Smarter Decision-Making Across Complex Supply Networks

Is Agentic AI the Next Big Thing in Supply Chain?

Over the next 12 to 18 months, we anticipate seeing more businesses implement agentic AI in their supply chains as the technology continues to advance quickly. Supply chain executives need to clearly demonstrate how this technology enhances key metrics and KPIs, building a strong business case for adoption. This entails proving increases in forecasting precision and proactively modifying processes to prevent downtime or cargo rerouting to prevent interruptions.

Additionally, even as tasks are automated, supply chain managers must remember that agentic AI might not completely replace current resources. Although the technology can increase supply chain autonomy and efficiency, it will require integration with current workstreams and personnel, including the teams responsible for providing oversight. Going forward, the human aspect will remain crucial, especially as organizations look for problems with bias and hallucinations that have previously followed Gen AI rollouts. Let AI automate the repetitive tasks and allow human staff to do the critical thinking to solve problems.

Early adopters of the technology will also need to show how agentic AI can work with other AI-powered systems to provide a comprehensive supply chain view that enhances risk management, operational effectiveness, and forecasting accuracy. This will enable them to build stronger, more resilient supply chains, positioning businesses to thrive in an increasingly volatile and unpredictable world.

What Should COOs Do Now in Agentic AI in Supply Chain?

The first step for COOs who want to begin using agentic AI in their supply chain is to identify the major business challenges rather than adopting the most recent AI technology.

- Define a clear business outcome from the start. Define the result you want so agents can be designed to achieve it.

- Check your data. Ensure you have the right datasets to solve the problem or identify where to source them.

- Partner with technology vendors to leverage existing solutions. Leaders like SAP are building AI agents and platforms, reducing the need to start from scratch.

Today’s supply chains are filled with challenges that agentic AI can solve. These intelligent agents enable seamless data sharing and integration across global businesses, even when formats, standards, and systems differ. Unlike traditional rules-based automation, agentic AI learns from historical data, predicts disruptions, and automatically adjusts plans in real time, reducing manual intervention and improving resilience in dynamic, complex supply chain environments.

Even more encouraging is the fact that interactions between COOs, CFOs, and the rest of the C-suite become much more cooperative when data can be shared and integrated throughout the company. This ensures that their departments are collaborating to identify bottlenecks and apply the proper ratio of independence to restraint.

Conclusion

Agentic AI is redefining how businesses tackle disruptions, optimize operations, and build resilient supply chains. By moving beyond static, rules-based systems it empowers organizations to anticipate risks, automate decisions, and unlock new levels of efficiency. From predictive analytics to adaptive planning, Agentic AI ensures companies can thrive in today’s volatile, fast-moving markets.

At NextGen Invent, we bring this future to life with our advanced supply chain logistics management software solutions, designed to streamline workflows, strengthen visibility, and improve inventory management in supply chain management. Whether you’re aiming to reduce costs, accelerate decision-making, or enhance customer satisfaction, our tailored platforms help you achieve measurable business outcomes.

Partner with NextGen Invent to transform your supply chain into a competitive advantage and power your next big revolution.

Frequently Asked Questions About Agentic AI in Supply Chain

Related Blogs

AI in Supply Chain: Embracing Future with Gen AI & Automation

Integrating Gen AI, automation, and AI in supply chain is a transformative force. These technologies offer a shift in how supply chains operate, providing avenues for enhanced efficiency, agility, and adaptability.

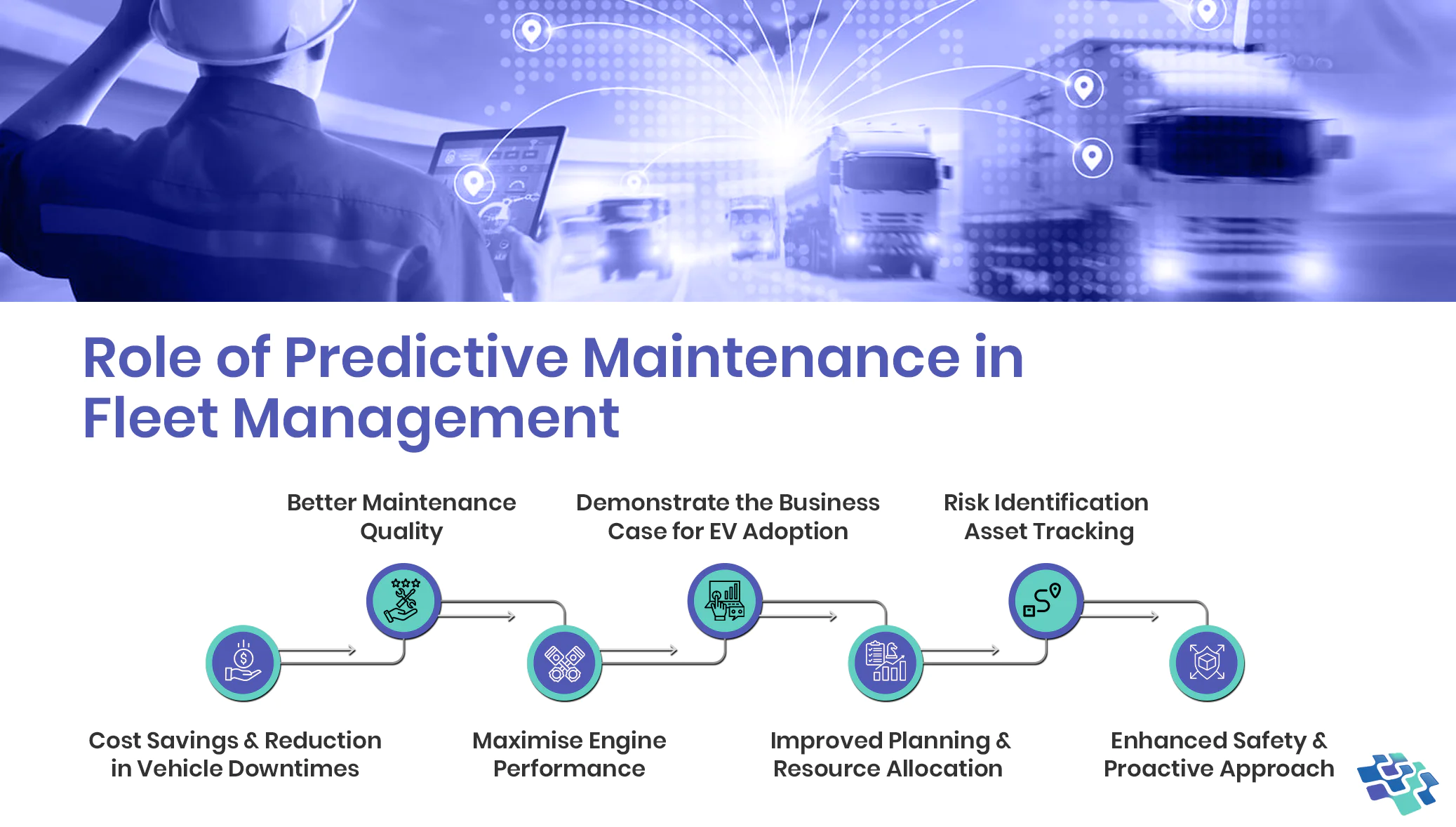

How Fleets Can Maximize Uptime and Efficiency with Predictive Maintenance?

Predictive maintenance has been shown to, boost vehicle availability by 20% , lower maintenance costs by up to 25%, and prolong the lifespan of machinery by several years.

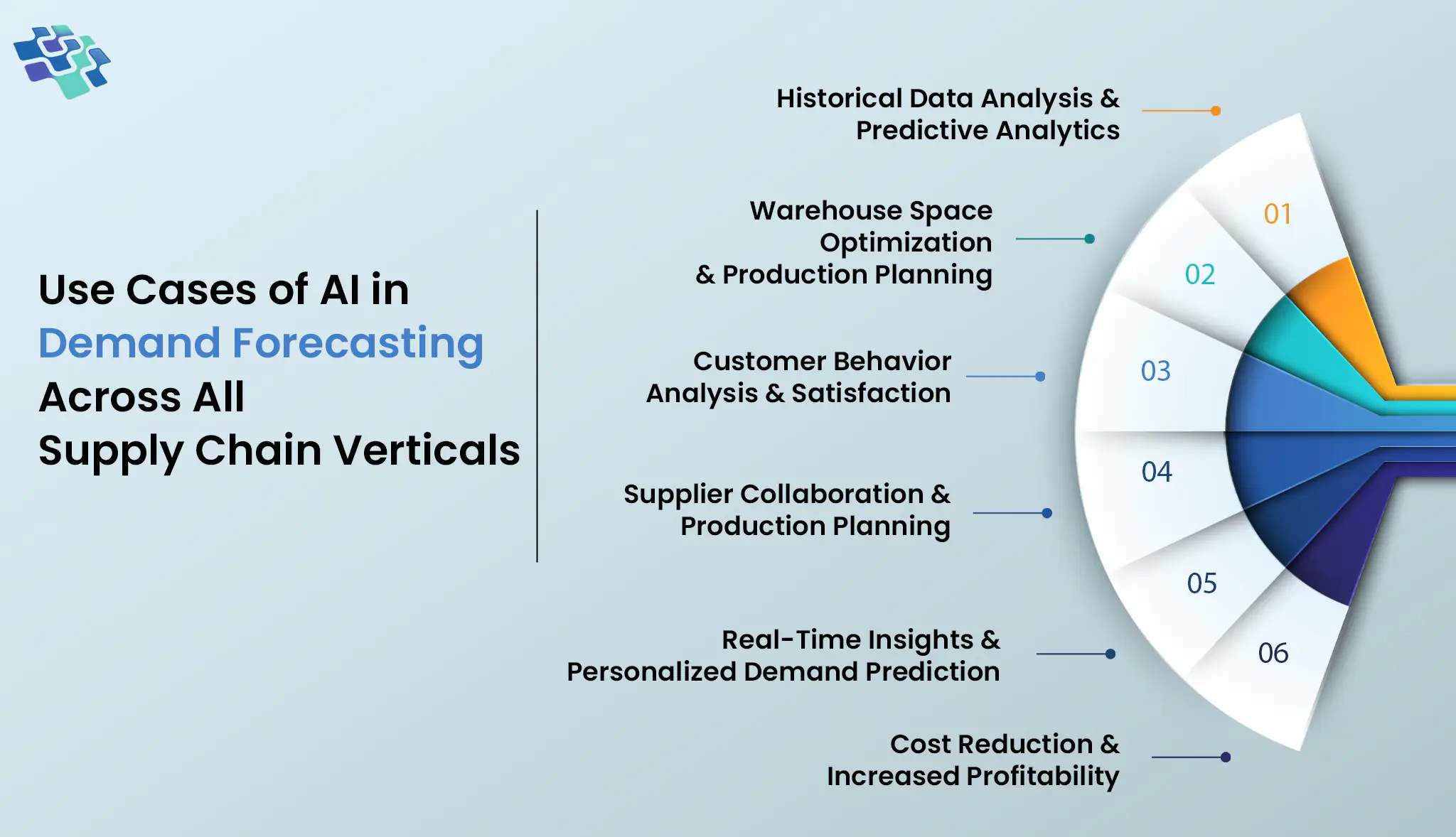

Use Cases of AI in Demand Forecasting Across Supply Chain Verticals

The planning portion of SCM begins with demand planning. The important questions of what, when, where, why, and how consumers will desire products and services are addressed to enterprises.

Stay In the Know

Get Latest updates and industry insights every month.

1. Data Cleansing & Anomaly Detection

1. Data Cleansing & Anomaly Detection