How AI in Manufacturing is Transforming the Industry?

Bridging the gap requires upskilling, cultural shifts, and substantial financial commitments. Implementing AI in manufacturing demands a robust technical foundation, a challenge often underestimated. Businesses should prioritize experimentation and strategic investments for AI in manufacturing to propel the industry toward a future of enhanced efficiency and innovation.

Maximize Your Manufacturing Potential: AI Mastery for Precision, Quality, and Speed Like Never Before

“Over 70% of respondents say they have implemented some form of AI into their operations already. Automation software is the most used type of AI at this stage (60%), though manufacturers are exploring other types, including Predictive AI (37%) and Generative AI (35%).”– Businesswire

AI in Manufacturing: Overview

In manufacturing, the synergy between artificial intelligence and industrial IoT, facilitated by smart factories, leverages extensive data streams. Manufacturers increasingly employ AI solutions, including deep learning neural networks and machine learning, for enhanced data analysis and decision-making. Predictive maintenance stands out as a prominent AI application, optimizing maintenance schedules and predicting failures, resulting in cost-effective upkeep of production lines. Improved demand forecasting and material waste reduction are just some of the many benefits of AI in manufacturing and production. The seamless integration of manufacturing and AI becomes imperative, as industrial environments demand a harmonious collaboration between humans and robots. The transformative potential lies in harnessing AI’s capabilities to refine processes and efficiency within the manufacturing landscape.

Artificial Intelligence Segments Impacting Manufacturing

The term artificial intelligence refers to a broad range of learning system characteristics that are thought to represent intelligence. These include sophisticated simulation, prescriptive modeling, sophisticated automation, image and video recognition, and complex analytics, to name just a few. The following technologies are key to AI application cases in industrial processes:

- Machine Learning: Automating the process of learning from underlying patterns using data and algorithms without the need for explicit programming.

- Deep Learning: A branch of machine learning that analyzes objects like photos and movies using neural networks.

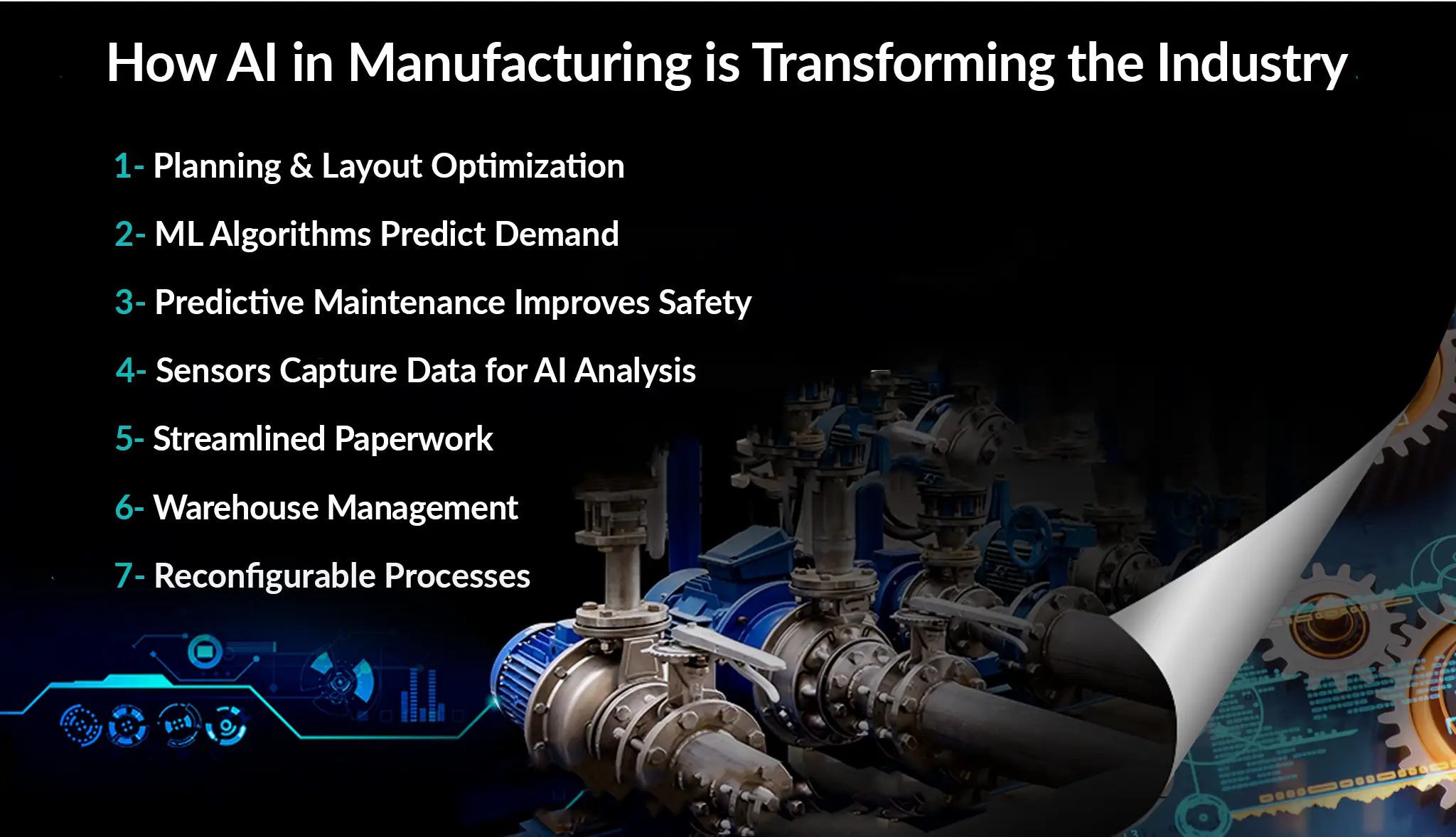

How AI in Manufacturing is Transforming the Industry

AI in manufacturing is triggering a shift, unlocking unprecedented breakthroughs and efficiencies through automation. Explore the top 7 use cases of artificial intelligence in manufacturing industry, showcasing its transformative impact on the sector.

1. ML Algorithms Predict Demand

1. ML Algorithms Predict Demand

Artificial Intelligence in manufacturing utilizes machine learning algorithms to discern human purchasing trends, offering valuable insights to producers. These algorithms can discern patterns indicative of increased demand for specific products, allowing producers to proactively adjust production. The predictive prowess of AI enables producers to anticipate high-demand scenarios before retailers express their needs. AI systems, through a nuanced analysis of consumer behavior, elevate the strategic planning of production cycles. This mutualistic alliance between AI and manufacturing optimizes supply chains, ensuring the timely availability of in-demand goods. Essentially, AI-powered machine learning orchestrates a transformative narrative in manufacturing, instilling agility and responsiveness to market dynamics. This synergy facilitates more efficient and informed production decisions, aligning the industry with the demands of an ever-evolving market landscape. The integration of AI in manufacturing, particularly through machine learning, emerges as a cornerstone for enhanced adaptability and strategic acumen in production processes.

2. Predictive Maintenance Improves Safety

AI in manufacturing is increasingly pivotal for predictive maintenance in facilities, railroads, and heavy equipment usage. Neglecting equipment upkeep poses financial and temporal risks. Premature maintenance squanders resources, while delayed action can lead to severe wear, endangering both equipment and personnel. AI-based PdM systems (Predictive Maintenance) mitigate these challenges by foreseeing maintenance requirements. They optimize timing, ensuring timely interventions to prevent both premature and overdue maintenance scenarios. By leveraging AI, organizations gain insights into the precise types and timing of replacement component needs, streamlining resource allocation and safeguarding against potential risks. In essence, the integration of AI in manufacturing for predictive maintenance enhances operational efficiency, minimizes downtime, and safeguards investments in equipment and workforce safety.

3. Layout Optimization

The impact of artificial intelligence in manufacturing goes beyond the production process, in particular affecting production planning. Facility layout, shaped by factors like operator safety and process flow efficiency, demands adaptability for short-term projects or procedural changes. Frequent reconfigurations, however, introduce material and space conflicts, posing challenges to efficiency and safety. In addressing these issues, sensors become instrumental in tracking and quantifying conflicts. AI emerges as the solution, leveraging sensor data to optimize manufacturing design intelligently. This application of AI in production planning fosters adaptability, reduces conflicts, and ensures streamlined and secure operations. It underscores AI’s expansive role in manufacturing, emphasizing its strategic contributions to planning, resource optimization, and resolution of challenges linked to evolving production demands. The synergy of AI and manufacturing extends far beyond the shop floor, reshaping the landscape of production planning for enhanced efficiency and safety.

4. Sensors Capture Data for AI Analysis

Implementing uncertain technologies like additive manufacturing requires a critical step: nondestructive testing (NDT) post-production. NDT, particularly with capital equipment like CT scanners, assesses structural integrity, but the cost can be high. Machine sensors, connected to data-rich models, aid in post-manufacturing analysis. Machine learning models, constructed from sensor data, correlate with CT scan defects, identifying potential malfunctions without additional scans. Sensors also monitor tool utilization, capturing reliable data for AI processing. AI adapts manufacturing tools and procedures to diverse environments, addressing factors like humidity. Factory humidity sensors reveal unexpected outcomes, such as issues in moisture-controlled areas caused by open doors. Efficient AI models are crucial for interpreting sensor data, enabling proactive issue prediction and immediate troubleshooting alerts. The future holds AI-driven solutions for preemptive issue resolution and enhanced production processes in manufacturing.

5. Reconfigurable Processes

AI enhances manufacturing processes, elevating adaptability and reconfigurability. Dynamic factory floor layouts are determined by current demand, and predictive models strategize for future requirements. AI facilitates “what-if” analysis, optimizing process sequencing and shop floor layouts. For instance, evaluating whether to prioritize a high number of expensive additive machines or numerous smaller ones for varied projects based on demand fluctuations. AI-driven decisions extend to 3D printing, considering factors like thermal treatment. Engineers use what-if scenarios to optimize equipment choices, potentially outsourcing processes to neighboring companies. AI alters business cases, determining if a factory concentrates on one captive process or diversifies for robustness. Struggling industries, like aerospace, could pivot to include medical part production, showcasing the transformative role of AI in shaping versatile and resilient manufacturing ecosystems.

6. Warehouse Management

Artificial Intelligence is reshaping warehouse management in the manufacturing industry, ushering in transformative improvements. AI-powered manufacturing solutions and machine learning enhance productivity, accuracy, and cost-effectiveness in warehouse operations. A pivotal application lies in inventory management, where AI analyzes historical sales data, current stock levels, and market trends to precisely forecast demand patterns. This optimization ensures product availability while minimizing carrying costs through inventory level adjustments. Take a clothing business using AI-based forecasting; it adapts inventory levels based on historical sales data and external factors, preventing stockouts and overstock situations. AI systems also enhance warehouse order fulfillment processes, allocating resources, optimizing routes, and analyzing orders for faster and error-free processing, resulting in increased customer satisfaction. For instance, BMW employs AI-powered automated guided vehicles (AGVs) to enhance intralogistics in manufacturing warehouses. AGVs automate material and finished goods delivery along predefined routes, enhancing inventory visibility and management. The adoption of AI in manufacturing significantly elevates warehouse management, revolutionizing efficiency and cost-effectiveness, from inventory optimization to accelerated order fulfillment.

7. Streamlined Paperwork

A notable application of AI in manufacturing is Robotic Process Automation (RPA), specifically targeting paperwork automation. In manufacturing, processes like handling purchase orders, invoices, and quality control reports involve numerous documents, prone to human errors and delays. Integrating conversational AI for manufacturing introduces intelligent bots that automate administrative tasks. These AI-enabled bots autonomously extract, classify, and categorize data from documents, seamlessly entering it into relevant systems. For instance, automakers can deploy RPA bots for managing supplier invoices. These bots eliminate the need for manual data entry by efficiently collecting pertinent elements, validating them against predefined standards, and seamlessly entering the data into accounting systems. This integration of AI and RPA in manufacturing optimizes workflows, reduces errors, and enhances efficiency by automating labor-intensive administrative processes.

Challenges in Implementing AI in Manufacturing

Deploying AI in manufacturing brings immense potential but requires addressing key concerns. Data security, algorithmic biases, interoperability, skills gap, and the balance between automation and human roles must be carefully considered for successful implementation and industry advancement.

- Security Considerations: As AI systems become more widespread in manufacturing, ethical and security concerns escalate. Careful development and implementation are vital to eliminate biases and uphold privacy. Robust cybersecurity measures are imperative to safeguard AI systems from potential intrusions, underscoring the need for a comprehensive approach to address ethical and security considerations in the evolving landscape of AI in manufacturing.

- Data Collection and Integration: AI systems require substantial data for effective learning, but aggregating data from diverse sources can be challenging. Manufacturers need to ensure data consistency, accuracy, and proper labeling for AI systems to yield accurate results. A meticulous approach to data curation is crucial to enhance the reliability and performance of AI in manufacturing, emphasizing the significance of high-quality, well-organized data for optimal system functionality.

- Workforce Training and Skill Development: Integrating AI in manufacturing demands a skilled workforce capable of developing, implementing, and managing AI systems. Manufacturers must invest in training and upskilling initiatives to ensure their staff possesses the requisite knowledge and skills for effective collaboration with AI technologies. Prioritizing workforce development is essential for successful AI implementation in manufacturing, emphasizing the need for continuous learning and skill enhancement within the industry.

Future Trends & Innovation of AI in Manufacturing

AI’s future impact on manufacturing is anticipated to be revolutionary, enabling innovation and competitive advantages for manufacturers. As AI technologies evolve and become more accessible, the manufacturing sector is poised to leverage these opportunities, ushering in transformative advancements and strategic benefits. The integration of AI in manufacturing holds the potential to reshape industry dynamics significantly.

- Intelligent Automation: AI-driven automation is poised to advance, tackling complex tasks once exclusive to humans. This evolution promises more efficient operations and reduced costs. By handling repetitive tasks, AI frees up human workers for innovation, creativity, and problem-solving, marking a transformative shift in manufacturing processes.

- Continuous Improvement: AI facilitates continuous improvement in manufacturing by analyzing data from various sources. Algorithms detect opportunities to streamline processes, enhance productivity, and improve products, allowing manufacturers to stay competitive and foster innovation through an iterative approach to improvement.

- Smart Factories: The integration of artificial intelligence in “smart factories,” where machines and networked systems communicate in real-time, enhances productivity, minimizes waste, and streamlines coordination across manufacturing processes. This AI-centric approach results in increased output, reduced costs, and heightened customer satisfaction.

AI remains crucial for streamlining procedures and enabling real-time decision-making in manufacturing. Utilizing AI systems, manufacturers can analyze data from diverse sources, identify trends, and allocate resources more efficiently. This leads to improved decision-making, enhanced quality control, and cost savings. Overall, the integration of Artificial Intelligence in the manufacturing industry is poised to transform the sector, boosting productivity, efficiency, and competitiveness, ushering in significant operational and production improvements.

How NextGen Invent is Empowering Manufacturing with AI/ML Solutions?

NextGen Invent, a leading AI app development services company, is at the forefront of revolutionizing the manufacturing sector. Leveraging profound expertise in manufacturing processes and AI, our engineers empower manufacturers to streamline operations. Our AI solutions automate processes, enhancing output and efficiency. Utilizing AI algorithms, we analyze large datasets to identify bottlenecks, forecast maintenance needs, and optimize resource allocation. This results in cost reduction, improved decision-making, and enhanced quality control for manufacturers. Beyond solutions, we provide comprehensive support and advisory services, addressing ethical and security concerns, workforce training, and seamless data integration.

As a dedicated partner, NextGen Invent guides manufacturers through AI implementation challenges, ensuring they stay ahead in the era of AI-driven innovation. Schedule a meeting to harness innovation and propel your manufacturing business into the next generation with our expertise in AI.

Read Related Blogs

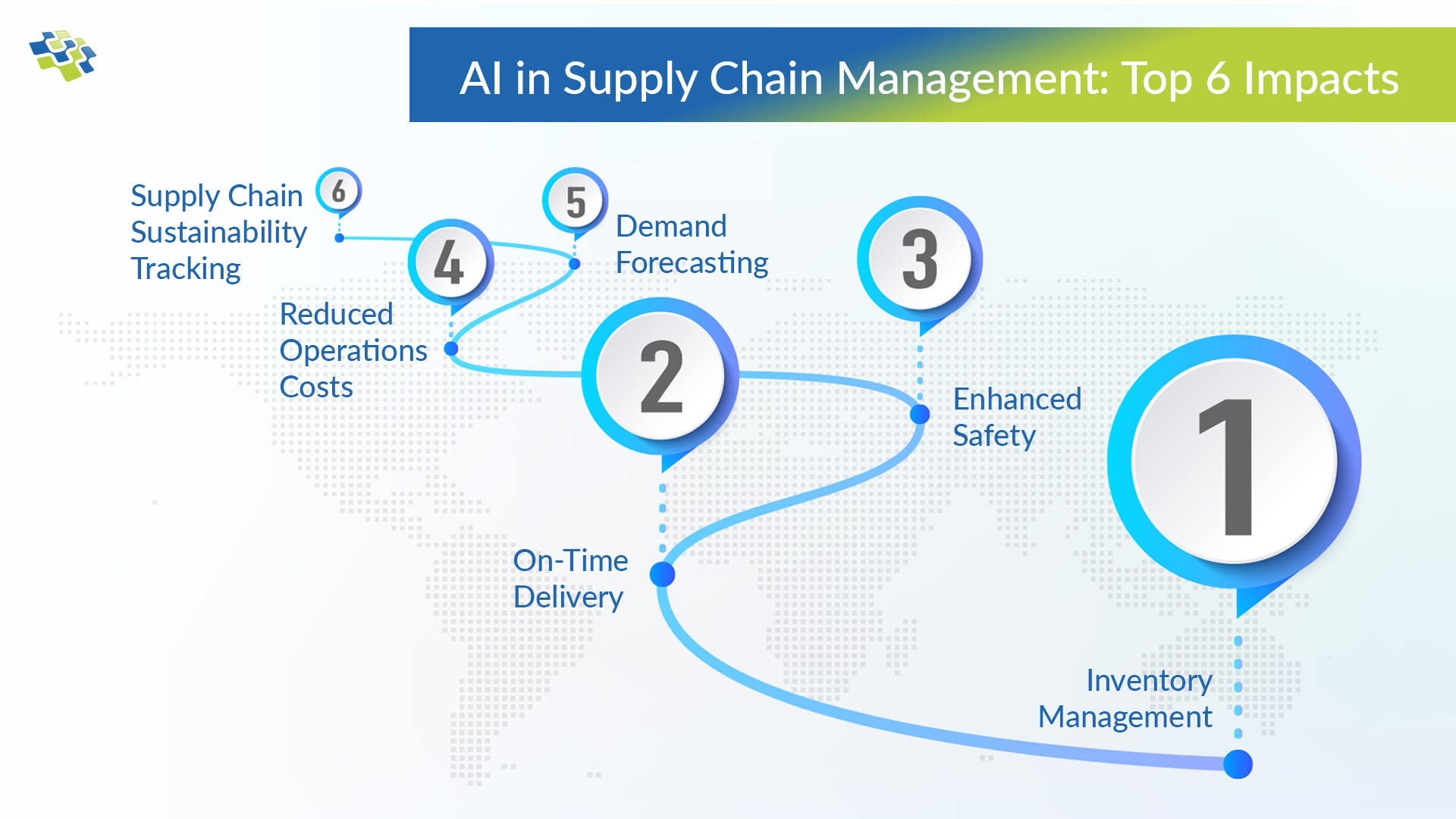

How AI Is Impacting Supply Chain Management?

Industry experts are certain that AI in supply chain management will “change the game”. It is rapidly emerging, with the ability to process vast amounts of operational data generated by a range of sources, including cloud-based applications and sensors.

How Can AI Transform Your Retail Business?

In the current global economy, retail enterprises must put profit and productivity first. To be successful and keep a step ahead of the competition, rapid and effective action is required. AI in retail can enhance operations, boost revenues and streamline workflows.

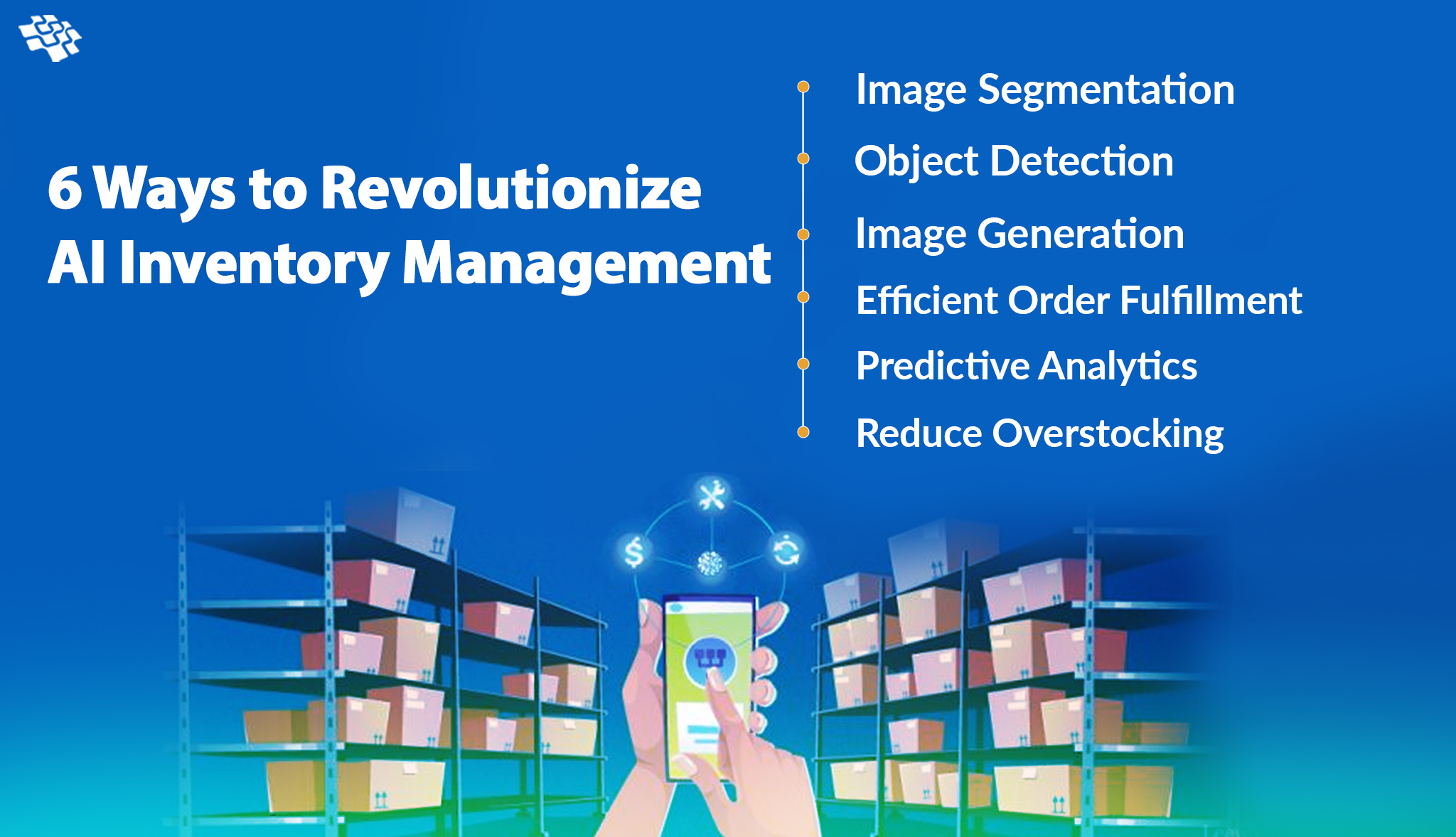

How CV is Revolutionizing AI Inventory Management?

AI inventory management is revolutionizing large-scale corporate operations by enhancing efficiency and accuracy. Through precise product location tracking, this innovative technology optimizes processing and stocking, ensuring seamless movements with the right force.

Stay In the Know

Get Latest updates and industry insights every month.

1. ML Algorithms Predict Demand

1. ML Algorithms Predict Demand