How AI is Reducing Energy Consumption in Manufacturing Industries?

AI will enable connection to information, which will assist concepts like energy flexibility and demand optimization. It has advanced rapidly, outpacing human abilities in complicated tasks, from explainable algorithms to deep learning systems.

Facing Inefficiencies in Energy Management? Leverage Our AI Expertise for Sustainable Manufacturing Operations

“Artificial intelligence can improve energy efficiency by increasing technological efficiency. AI can also shorten the gap between businesses and optimal energy efficiency by improving technological efficiency. On the one hand, artificial intelligence can also improve production efficiency.”- NCBI

Using AI to Reduce Energy Consumption in Manufacturing Industries

It is naive to think about the energy expenses associated with AI in a vacuum, even if these costs are unavoidable and require a substantial amount of electricity to operate. In addition to covering these expenses, AI will open up chances for

- Energy savings,

- Lowering the company’s overall carbon footprint.

Artificial Intelligence has already proven useful in streamlining manufacturing operations, monitoring the electrical grid, and improving energy management. To be more precise, AI and deep learning can be used to anticipate the reasons behind grid breakdowns, which makes important preventative maintenance possible.

The precise potential advantages across all industries are impossible to measure, but artificial intelligence will save 15% of the world’s energy by 2040. However, AI also provides many options for energy savings across businesses, which can help offset these expenses and reduce energy consumption in manufacturing industries.

Steps to Integrate AI for Efficiency & Energy Consumption in Manufacturing Industries

Several actions must be taken to successfully integrate AI for efficiency and energy consumption in manufacturing industries:

- Define Objectives: Establishing precise goals for energy optimization is the first stage in the process. This can be cutting back on energy use, enhancing the effectiveness of processes, or eliminating waste.

- Collection of Data: For AI systems to make choices, data is necessary. As a result, having a reliable system in place for data collection is essential. This entails gathering information from various sources, such as machine functions, energy consumption, and environmental aspects.

- AI Model Development: After the data is gathered, AI models can be created using it. These advanced and complex models ought to be built with data analysis and energy consumption forecasting in mind.

- Integration: Following their development, the AI models ought to be included in the current industrial procedures. This can entail building a central AI system that manages the entire operation or integrating AI algorithms into machinery or industrial lines.

- Adjustment & Monitoring: It is imperative to consistently monitor and modify the AI system in response to its performance after it has been put into place. This ensures that the system stays efficient over time and permits continuous improvement.

Facing Energy Consumption Challenges? Implement Our AI Systems for Smarter, Greener Manufacturing Operations

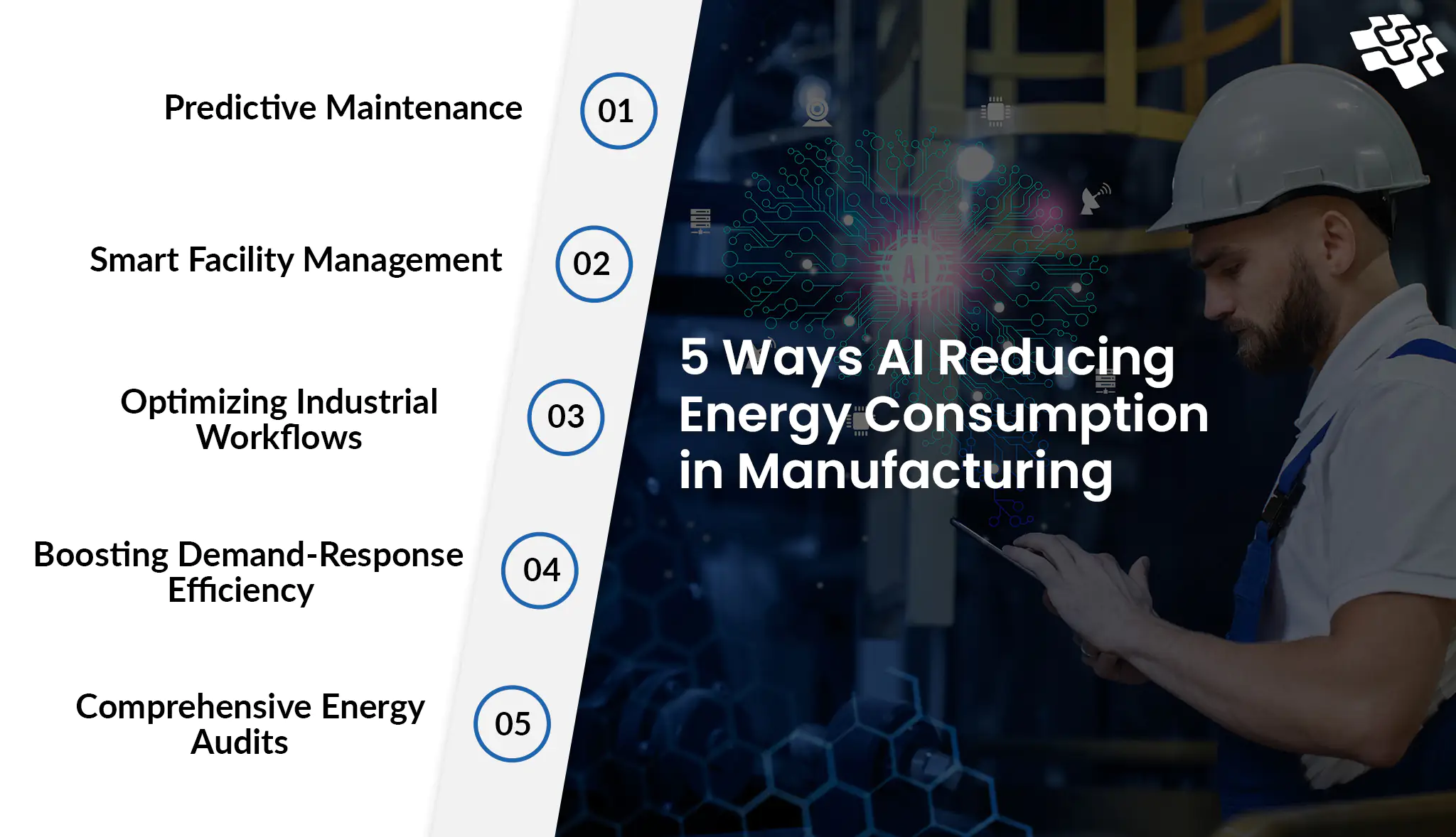

5 Ways AI Reducing Energy Consumption in Manufacturing Industries

Machine-learning algorithms can be used in the manufacturing industry to develop a model of energy demand and utilization. Alerts are generated by AI-driven systems when forecasts deviate from a benchmark. This reduces or eliminates production errors that can usually result in higher energy usage.

1. Predictive Maintenance

1. Predictive Maintenance

The goal of predictive maintenance AI software solutions is to increase asset productivity by foreseeing equipment failures. In the manufacturing industry where machinery plays a significant role, an operator’s ability to reduce efficiency losses increases with the speed at which they can resolve an issue that sets out an alert. This can be achieved by putting status monitoring into practice.

- By recommending an asset output schedule for maintenance personnel to adhere to, predictive maintenance can reduce inspection costs by up to 25% and maintenance costs by up to 10%.

- Artificial intelligence algorithms can distinguish between data noise and vital signals, allowing them to identify faults and send alerts to maintenance supervisors, who then investigate the problem and fix it.

Therefore, if sensors identify an energy leak, for example, predictive maintenance AI software solutions can minimize inefficiencies, avert major operational expenditures, and prevent temporary shutdowns to fix machinery. Predictive maintenance increases potential savings by minimizing equipment downtime resulting in energy consumption in manufacturing industries.

2. Smart Facility Management

AI-driven systems convert conventional solutions into intelligent responses. Real-time data on the energy usage habits of enterprises is gathered by industrial AI. These can be combined with other IoT sensors to optimize ventilation, heating, cooling, and lighting, including smart meters and thermostats.

Customized energy insights are one benefit of smart facility technologies. Artificial Intelligence identifies moments of peak energy usage and finds inefficient and wasted energy locations. Businesses can implement sustainable energy management systems and regulate their energy consumption for optimal efficiency by utilizing this automation.

3. Optimizing Industrial Workflows

AI plays a crucial role in minimizing energy consumption across manufacturing sectors. Tasks can be automated by intelligent automation, and early defect detection and quality control can be achieved via machine vision. This approach not only cuts down on emissions and wasteful material use but also reduces physical labor.

While current automation requires human oversight for optimal functioning, it markedly boosts productivity and accelerates operational efficiencies. This integration underscores AI’s capacity to streamline manufacturing processes sustainably and economically.

4. Boosting Demand-Response Efficiency

Energy utilities harness AI to analyze data and forecast spikes in energy demand based on industry trends. Using this insight, targeted demand-response programs are deployed, offering incentives for consumers to reduce usage during peak times. This strategic approach flattens demand curves, enabling utilities to avoid unnecessary distribution of additional power to meet temporary surges.

By integrating AI-driven demand-response strategies, utilities optimize energy distribution efficiency, ensuring reliable and sustainable power delivery while incentivizing consumers to participate in energy conservation efforts. This synergy between technology and consumer engagement marks a pivotal shift towards a more resilient and efficient energy ecosystem.

5. Comprehensive Energy Audits

AI enables automated energy audits for manufacturing factory buildings, recommending customized improvements based on comprehensive assessments. Factors such as insulation requirements, equipment upgrades, occupancy trends, and local weather conditions are meticulously analyzed to generate detailed insights. This automated approach accelerates the audit process, delivering faster and more precise results compared to traditional manual inspections.

While oversight ensures the accuracy and reliability of AI-generated recommendations, this technological advancement significantly enhances operational efficiency in optimizing building energy performance.

Struggling with High Energy Costs? Discover Our AI Solutions to Optimize Your Manufacturing Processes

Final Thoughts on AI for Energy & Sustainability

One aspect of society that has not changed is its key infrastructure, even as we look to the future and developing technologies. The infrastructure of manufacturing, telecommunications, water supplies, and power grids is critical to sustainable development. Artificial Intelligence will play a critical role in addressing the issues that lie ahead as network security gets more intricate. Ultimately, demands for accountability and openness about our energy sources will only grow as climate action and carbon regulations advance.

Some CSPs have already made the switch to 100% renewable energy, publicly urging other manufacturers to follow suit, and emphasizing this in their communications. They are in discussions with grid utility companies regarding the availability of more open data from the grid network regarding the percentage of renewables or the energy used carbon footprint. As industry and the public demand more detailed information of this kind, artificial intelligence will play a further role in tracking and evaluating those sources. In the end, even though this field is developing quickly, no one can afford to fall behind.

Wrapping Up

Globally, artificial intelligence has the potential to be a game-changing technology. However, this technology’s progress is still limited by its equally large energy footprint. The size and complexity of AI are growing, which presents both financial and environmental challenges. These range from the possible financial burdens on people who use the technology to the carbon footprints resulting from the enormous processing requirements. A legacy of worldwide innovation and conservation for the future must be left by businesses, governments, and researchers alike since the sustainable evolution of AI requires them to give the sustainability factor top priority in the development of AI.

Fortunately, NextGen Invent, a leading AI software development services company, already understands how critical it is to build a more sustainable AI future. Our AI data scientists prioritize the environment alongside technological breakthroughs through hardware innovations, software optimization, carbon offset schemes, renewable energy adoption, and algorithms.

Frequently Asked Questions About AI in Energy Consumption

Related Blogs

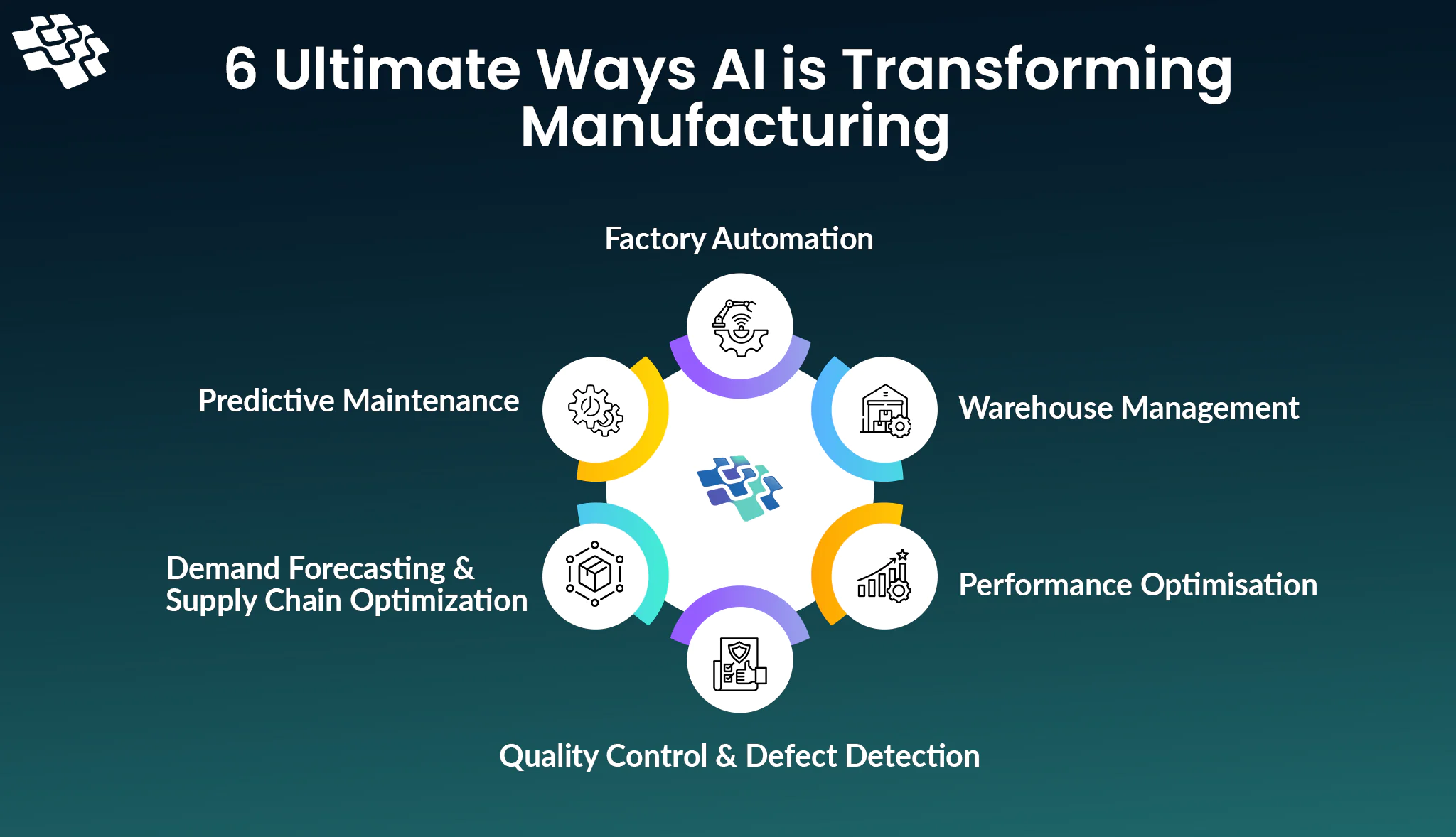

How AI in Manufacturing Industry is an Ultimate Game Changer?

What if machines could think, learn, and make decisions like humans? AI is already here and is revolutionizing the manufacturing industry, so don’t worry if it sounds like a sci-fi idea. Experts estimate that AI in manufacturing industry will reach...

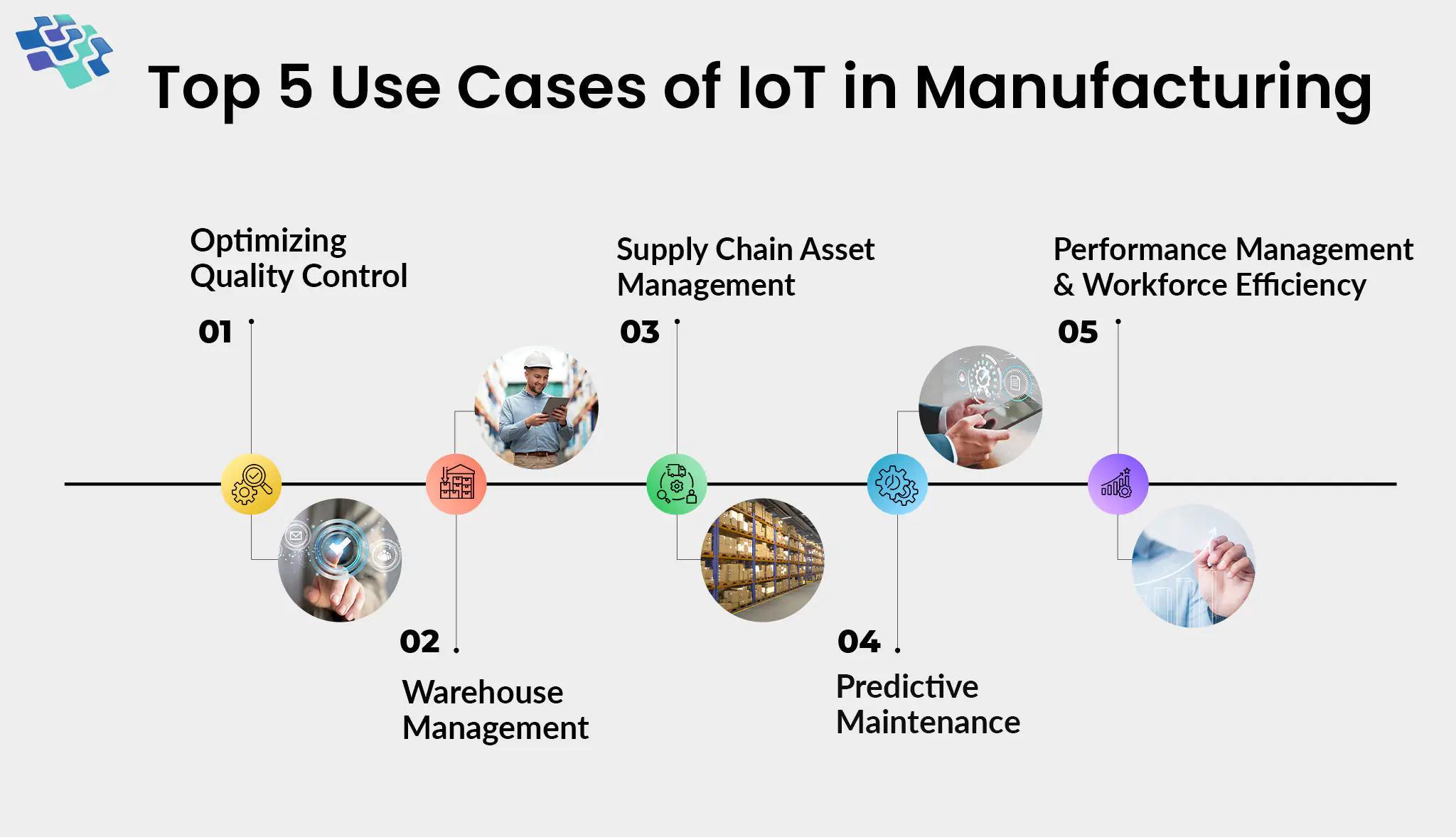

How IoT in Manufacturing is Revolutionizing the Industry?

IoT in manufacturing is now a key factor that is changing the ever-changing Industry 4.0 landscape. The way industries use data, interact, and function has changed as a result of IoT. In fact, according to a survey of executives in the manufacturing industry, 86% of them...

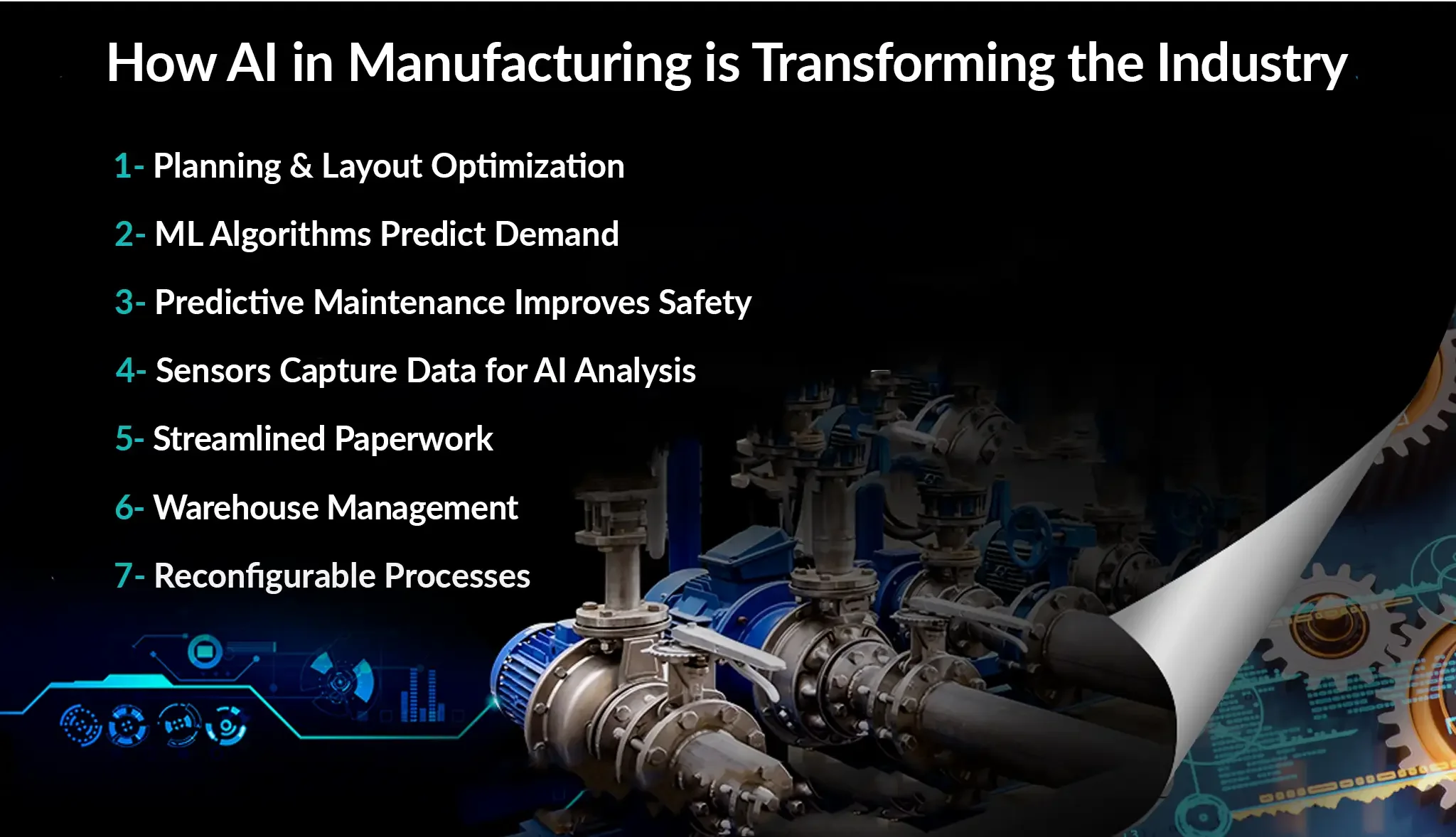

How AI in Manufacturing is Transforming the Industry?

A fiercely global economy can be kept competitive with the advent of AI in manufacturing industry. The integration of artificial intelligence in manufacturing brings transformative potential, employing algorithms to process data from sensors and human inputs.

Stay In the Know

Get Latest updates and industry insights every month.

1. Predictive Maintenance

1. Predictive Maintenance