How Artificial Intelligence is Transforming Cold Chain Logistics?

AI supply chain logistics management software solutions are feed with the factors in the meteorological data—based on the date, destination, and shipping origin—into a machine learning algorithm to make predictions about the temperature in the shipping lane and provide the results in a user-friendly graphical style. The machine learning model determines the projected heat transfer to your packaging by utilizing your shipment date and time, lane temperature, and container temperature data.

Overcome Delayed Deliveries with AI-Driven Route Optimization for Efficient Cold Chain Management

“The integration of AI in modern warehouses also helps in database management, packaging, manufacturing, enhanced warehouse safety, and some other operations that help maintain cold chain logistics operations.”- Precedence Research

Recognizing Cold Chain Logistics’ Digital Transformation

In cold chain logistics, digital transformation involves more than just implementing modern technology. It’s about improving operations and processes and radically changing how businesses run.

Let’s say you must transport ice cream from manufacturing to retail. One of the most effective ways to ensure that ice cream remains completely frozen during the entire trip is to make use of innovative equipment. This is crucial because it keeps the ice cream from melting or spoiling. For instance, specialized trucks are now being built with sensors and computers that continuously check the temperature in place of standard trucks. The driver may receive an alert from the system if it gets too warm, advising them to fix the temperature breach. Thus, comprehending digital transformation entails being aware of how these innovative techniques and technologies maintain the safety and quality of our ice cream—or other items that are sensitive to temperature—during transportation.

Growth & Expansion in Emerging Markets

Due to a variety of economic variables that are affecting supply chain visibility worldwide, the cold chain logistics markets in the Asia-Pacific and Latin American regions are undergoing substantial shifts.

- With a real increase of about 3.5% forecast, the Asia-Pacific market is expected to lead global economic growth. The cold chain logistics sector in the region is expanding significantly. This expansion—with an anticipated increase from $142.71 billion in 2023 to $215.43 billion by 2028—sees growing consumer demand for premium products, a fast-expanding pharmaceutical industry, and a spike in ecommerce.

When compared to Western markets, this region’s cold storage capacity is restricted, which presents issues.

- Concurrently, due to the robust U.S. economy and the slowdown in Chinese growth, Latin America finds itself at a crossroads in its economic history. The region’s cold chain market is expanding despite inflation and rising interest rates brought on by pressures from the global economy.

This growth is being fueled by the quick exchange of perishable goods across international borders, advancements in refrigeration technology for transportation and storage, the building of infrastructure, and the growth of food chains by multinational companies.

Challenges of the Cold Chain Logistics Industry

The industry has grown rapidly due to the increasing demand for perishable commodities and the necessity for reliable and efficient temperature-controlled logistics. But the industry also faces challenges:

- Logistics & Transportation: Complex cold chain logistics are involved since perishable items have a time limit. High-level planning and coordination are needed to manage refrigerated vehicles, specialized storage, and effective routing, which raises expenses.

- Inventory Management: Effective inventory control guarantees product availability and reduces spoiling. Storage can be optimized with the use of methods like demand forecasting and real-time tracking, but it can be challenging to balance temperature control and dynamic demand.

- Temperature Control & Monitoring: It is imperative to keep the temperature precisely maintained to avoid spoiling. Although it can be difficult to manage several temperature zones and ensure uniformity, real-time monitoring, and alert systems are essential. Human mistakes and equipment malfunctions are additional concerns, especially in the pharmaceutical industry.

Maintain Strict Temperature Control Using AI to Prevent Product Spoilage During Transit

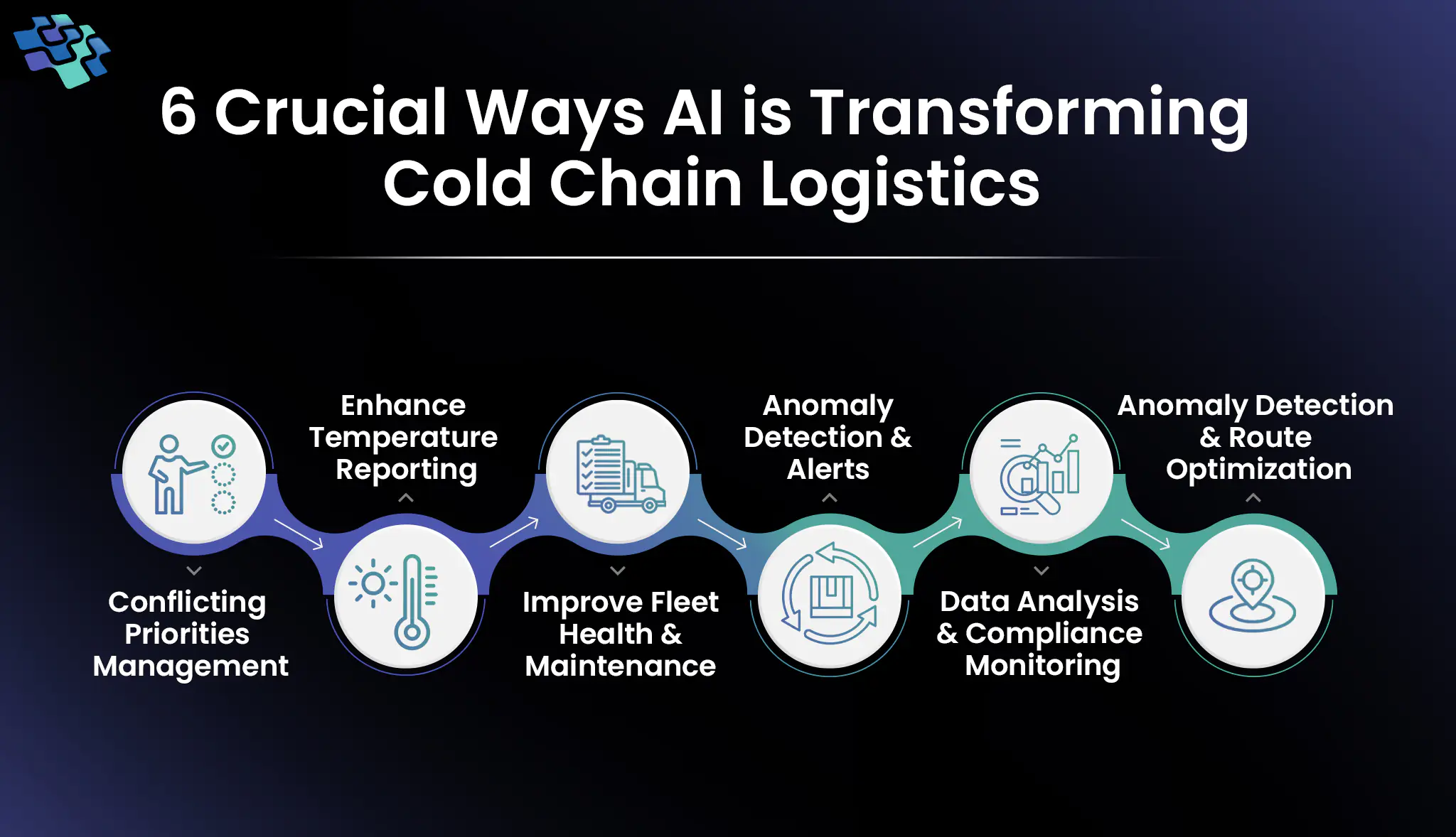

6 Crucial Ways AI is Transforming Cold Chain Logistics

These days, artificial intelligence is the talk of the town, and for good reason—it has potential uses in every sector of the economy, including logistics. These are six ways that cold chain logistics is being revolutionized by AI.

1. Conflicting Priorities Management

1. Conflicting Priorities Management

AI assists carriers in handling unforeseen disputes that result from operational choices. Optimizing your truck routes, for instance, can lead to more effective operations. However, because trailer doors must be opened more frequently, more efficient routing may lead to increased thermal abuse for reefer carriers. But with the help of technologies like two-way reefer controls and predictive data from AI, carriers can make the necessary corrections before an issue arises.

AI can assist carriers in understanding and effectively navigating the shifting landscape as expansion, complexity, and regulations change. AI will have to assist us in resolving unforeseen conflicts of priorities.

2. Enhance Temperature Reporting

Not only are manual temperature checks inefficient, but they can also be manipulated by deliberate deception or human error. Artificial intelligence in conjunction with specialized sensors and Internet of Things devices eliminates those issues and provides carriers and other stakeholders with real-time visibility by continuously monitoring the temperature of reefer trailers, even in separate compartments inside a single trailer. In addition to giving carriers more reliable and consistent temperature data, AI is also saving them a ton of money by removing the need for drivers to frequently stop and inspect goods.

Furthermore, product-specific algorithms can be used to find anomalies and fluctuations in temperature. AI can predict when a problem might occur and notify staff members in advance so they can take the necessary action by sending out automatic alerts. Real-time temperature data is compared with preset thresholds or anticipated temperature patterns to achieve this.

3. Improve Fleet Health & Maintenance

In addition to temperature monitoring, AI enhances predictive maintenance through advanced analytics. By examining historical data from vehicle and equipment components, AI systems can identify patterns and anomalies that signal potential failures. These systems leverage machine learning algorithms to forecast when specific parts are likely to fail, allowing for timely preventive repairs. This proactive approach reduces the risk of unexpected breakdowns and operational downtime, extending the lifespan of equipment.

By implementing such AI-driven predictive maintenance strategies, organizations can optimize their maintenance schedules, reduce repair costs, and improve overall operational efficiency.

4. Anomaly Detection & Alerts

AI algorithms can effectively detect temperature anomalies by analyzing real-time temperature data against predefined thresholds and expected trends. These advanced systems identify potential issues such as temperature excursions, equipment malfunctions, or unauthorized door openings. By continuously monitoring temperature readings, AI can quickly flag deviations that may compromise product integrity.

When an anomaly is detected, the system generates automated notifications to alert the relevant personnel, enabling swift action to mitigate risks. AI-driven monitoring safeguards product quality and maintains the integrity of sensitive environments.

5. Data Analysis & Compliance Monitoring

Artificial intelligence can analyze vast amounts of temperature data gathered from several reefers and produce useful insights. In addition to generating thorough reports for quality assurance, compliance audits, and strategic decision-making, it can spot trends and evaluate regulatory compliance.

AI can help make sure that cold chain logistics regulations and rules are followed. Artificial intelligence systems can evaluate compliance levels and provide detailed reports for auditing purposes by evaluating temperature data and comparing it with required temperature ranges or industry standards.

6. Route Optimization

AI-powered systems enable businesses and their customers to effectively track route progress, ensure temperature compliance, and manage exceptions in real-time. By leveraging advanced analytics and machine learning algorithms, these systems provide actionable insights that enhance visibility throughout the supply chain. Businesses can monitor critical parameters, such as temperature fluctuations and delivery timelines, facilitating prompt decision-making.

Additionally, automated compliance reporting simplifies regulatory adherence, reducing the risk of errors and improving overall operational efficiency. This comprehensive monitoring system enhances reliability, ensuring that goods are delivered safely and efficiently to customers.

Gain Real-Time Inventory Insights with AI Solutions to Minimize Stockouts and Overages

AI in Cold Chain Logistics: Future Full of Promises

Traditional business models will become outmoded and eventually obsolete as supply chain companies begin to focus more on results than products. Along the way, the bodies and brands of the losers and laggards will be left behind. Global supply chains and cold chain logistics are becoming increasingly ingrained, and this will put pressure on businesses to reduce costs wherever possible.

PwC estimates that by 2030, AI applications might revolutionize business practices and boost the world economy by up to $15.7 trillion. AI can now help logistics and supply chain optimization get the agility and precision that are sorely lacking. In cases when repetitive manual processes can be automated, it can also lead to a revolutionary rise in supply chain and operational efficiencies as well as a cost reduction.

Check Our Podcast: Why Supply Chain Resilience is Always in Season

The Things No One Tells You About Putting AI Into Practice

Actionable insights are produced by integrated AI technologies, which remove bottlenecks and provide value in real-time. This is significant because supply chain companies require increased execution rather than increased analysis. It is true that, depending on the size of the company, the cost of implementing a complete AI solution can vary from millions to tens of millions of dollars, but it can also seem overwhelming and prohibitively expensive.

Before integrating AI solutions, businesses must first complete a digitization process and then put in place an analytics program. Businesses frequently squander a lot of resources in this process as a result of failing to take end-user feedback into account and then having to go back and fix unforeseen issues. But there is an option. Organizations can start deploying AI in cost-effective ways by adopting an agile approach. They can start where they are, figure out what works for their company, and then build up as necessary by integrating third-party vendors.

Instead of starting from scratch or adding to existing solutions, this strategy enables significantly faster AI integration.

Wrapping Up

In 2025, cold chain management will be defined by significant advancements in sustainability and technology, all of which are related to the requirement for improved visibility. Cold chain logistics as we know it is changing because of these developments, which range from the transformative effects of AI and data analytics to the change in last-mile delivery technology.

At the front of this revolution, NextGen Invent provides state-of-the-art solutions that are customized to meet the changing requirements of cold chain management. Our advanced AI supply chain management solutions offer unmatched visibility and control over cold chain operations. NextGen Invent’s dedication to innovation and sustainability is in line with the latest developments in cold chain management, whether it comes to shipping high-value items, medications, or perishable commodities. Securing a competitive edge in the swiftly changing domain of cold chain logistics requires businesses or organizations to adopt our innovative artificial intelligence software development services. Reach out to us and take on these problems, whether your goal is to increase operational effectiveness, ensure product quality, or achieve sustainability objectives.

Frequently Asked Questions About Cold Chain Logistics

Related Blogs

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then...

Everything Businesses Need to Know About Warehouse Management Systems

Warehouse and distribution tasks need to be optimized, monitored, and managed by any large, complex logistics or supply chain company. These responsibilities include inventory management, order processing, and dock scheduling.

How to Overcome Challenges in Implementing AI in Supply Chain?

When it comes to the supply chain, AI technologies such as machine learning, deep learning, automation, and predictive analytics hold tremendous promise for transforming entire industries and organizations. However, achieving...

Stay In the Know

Get Latest updates and industry insights every month.

1. Conflicting Priorities Management

1. Conflicting Priorities Management