Everything Businesses Need to Know About Warehouse Management Systems

Businesses can save costs and boost the effectiveness and productivity of their warehouse by using a WMS that controls and automates all warehouse operations, from receipt and put away to storage, picking, packing, and shipment. However, based on a company’s needs, selecting the best WMS can be challenging.

Streamline Operations for Maximum Productivity And Optimize Inventory Accuracy & Labor Efficiency for Your Supply Chain Business!

“A WMS handles many functions that enable movements, including inventory tracking, picking, receiving, and storage. It also provides visibility into an organization’s inventory levels, aids in forecasting, facilitates inventory control, and advances material handling metrics at any time and location, whether in a facility or transit.”– TechTarget

Warehouse Management Systems: Overview

What exactly are warehouse management systems, and how do they work? Controlling warehouse operations is made possible for a business by a WMS. Receiving, the inventory procedure, and shipment are all included in this. Inventory locations and levels can be seen in real-time with the use of a software solution called WMS. Functions other than inventory control may also be included. Additional advantages include labor tracking, product traceability, kitting, and directed picking. Warehouse management systems can interface with back-end systems or function independently.

Some might also include an enterprise resource planning system (ERP). Businesses should weigh their options before proceeding with their WMS project. For example, from the perspective of data management, having two systems could be counterproductive.

Benefits of Using Warehouse Management Systems

Warehouse management system software solutions pay for themselves in numerous ways, even if they require a sizable initial investment. The following are the most important benefits of putting a WMS in place:

- Inventory Control: To avoid understocking and overstocking, inventory control entails keeping an eye on the amount of inventory in the warehouse. Businesses can save time by automating AI inventory management software for warehouses or by using warehouse management systems, which eliminates the need for frequent inventory level checks. When it’s time to order new items, the system will notify you instead.

- Improved Customer Service: A warehouse management system helps with customer service, although the connection might not be obvious at first. Since WMS provides businesses with real-time information on the number of things in stock and those that are out of supply, likely, customers won’t order items that are out of stock. Enhancements in warehouse management enable them to fulfill customers’ expectations for prompt deliveries by shipping goods or items more quickly.

- Traceability: Traceability and transparency are critical for customers and businesses alike. By monitoring the real-time location of products, businesses can pinpoint delays and bottlenecks in the supply chain. Real-time product tracking ensures that customers are aware of the arrival time of their orders. To deter fraud and counterfeiting, several product safety rules also demand that all the goods be traceable. From a safety perspective, being aware of a product’s origins and destination facilitates essential product recalls.

- Labor Tracking: A WMS’s labor management features allow businesses to monitor the performance of the warehouse labor in real time, providing valuable insights into your team’s workflow. Monitoring labor enables businesses to find potential bottlenecks in the logistics process, identify areas for development, and determine which workers can benefit from additional training.

Warehouse Management System vs Inventory Management System

An inventory management system (IMS) retains an accurate record of each SKU in the inventory, regardless of its location, whereas a warehouse management system (WMS) keeps an eye on warehouse operations including receiving and storing things and selecting and packaging orders. Warehouse managers are guided by a WMS’s inventory management tactics, including ABC classification when deciding where to put inventory. By using warehouse space strategically, this technique makes sure that high-demand products are always close at hand.

- By monitoring labor productivity, a WMS may assist warehouse operators in allocating inventory based on priority—for example, products nearing expiration—and in managing labor costs in the warehouse.

- Conversely, when combined with point of sale (POS) and shipping and logistics systems, AI inventory management software solution solely keeps track of orders, delivery, and sales.

- By examining past data and keeping an eye on sales trends, an IMS can also assist with demand forecasts to optimize inventory levels.

Although it is usually the first step in warehouse management, inventory management software is not always integrated with other warehouse processes. On the other hand, order management systems, transportation management systems, ERP systems, and warehouse management software all readily interface with one another to establish a coordinated and integrated network of processes.

Warehouse Management System Software: Key Features

Warehouse management systems are responsible for streamlining every step of the process, from receiving to shipping, in addition to inventory management. This includes the capacity to automate tedious tasks and synchronize operations both within and across warehouses, doing away with the need for spreadsheets.

1. Predictive Analysis

1. Predictive Analysis

The future of warehouse management systems lies in smart warehousing. A Bloom Berg survey indicates that over 40% of participants are giving priority to transforming their supply networks. Important components like IoT connectivity, machine learning, process optimization, predictive analytics, and real-time visibility are at the core of this change. Together, these components improve the accuracy, efficiency, and decision-making skills of warehouses and produce a smooth, flexible warehousing ecosystem.

Smart warehouse management systems combine real-time and historical data analysis to predict labor requirements, inventory needs, and future disruptions. These systems can build a digital replica to test various scenarios and improve forecasts because they have visibility into every part of the supply chain, including inventory levels, order statuses, equipment utilization, and even personnel performance. Warehouse managers can take advantage of opportunities, solve problems quickly, and keep efficiency at its highest level with the help of predictive insights.

2. Customer Management

Data interchange and communication with suppliers and consumers are made easier by modern warehouse management systems. It offers a consolidated location for order integration and vendor relationships. Faster onboarding and a better partner experience might result from the simplicity of interaction with the vendor’s systems provided by built-in connectors and ESBs. Sustaining continuous supply and demand fulfillment requires fostering good connections with customers. Better consumer experiences are directly correlated with more efficient vendor experiences, particularly in e-commerce.

- Orders from several sales channels can be combined by WMS, which can then prioritize them using fulfillment rules and other predetermined standards.

- Warehouse management systems enhance the customer experience by offering self-service capabilities to end users.

- Order tracking, precise deliveries, quick turnaround times, and a return policy all boost customer satisfaction and brand awareness.

The WMS offers a centralized hub for quickly identifying and resolving customer complaints to improve connections with vendors and consumers.

3. Performance & Workforce Management

Worker onboarding, assignment distribution, performance monitoring, and ongoing feedback can all be streamlined with warehouse management solutions. More effective warehouse operations depend on effective worker management. Businesses can reduce production gaps, match warehouse employees’ areas of specialty, and dynamically modify task scheduling using a centralized control system.

Businesses can find possible development areas using task management platforms, performance analytics software, and time-tracking solutions. Decisions on labor allocation for the best possible workforce management during seasonal peaks can also be made using these metrics.

4. Control Tower

In logistics, a warehouse management system serves as a control tower that provides a 360-degree perspective of all warehouse operations. It enables administrators to centrally monitor, detect, and resolve problems and bottlenecks. From a management and execution perspective, sophisticated analytics platforms, alert systems, and real-time dashboard visualization tools enable outstanding warehouse operations management.

The ideal warehouse management system (WMS) is a smart one, which can increase response times, and optimize resource allocation, and decision-making skills by combining granular visibility with reporting and analytics.

5. Order & Fulfillment Management

One of the most important aspects of a warehouse management system is order and fulfillment process optimization. Order fulfillment can be streamlined since the VMS manages a product’s actual flow through the warehouse. The ability to automatically place orders for products or parts that are frequently needed for resupply is another benefit of reorder functionality. Alternative WMS platforms offer convenient access to carrier networks, which can expedite shipping procedures.

Warehouse managers can now finally eliminate labor-intensive manual entry duties thanks to the growing adoption of automation integration.

6. Tracking & Analysis

Business intelligence from warehouse operations can be combined by manufacturers using several top WMS solutions. To be informed about when inventory levels are dangerously low or when there is excess stock, real-time tracking can be very helpful in maintaining an ideal inventory level and providing a comprehensive real-time perspective. Numerous workflow management solutions show what’s happening in a warehouse and where assistance is required.

Manufacturers may make timely judgments on necessary adjustments to critical business processes and help themselves plan for future developments by utilizing pertinent, high-quality data.

7. Inbound & Outbound Operations

A few functions of the warehouse inventory management software are designed to manage the initial stage of the warehousing operation, which involves interacting with several vehicles that deliver tangible goods and supplies. Truck manifest systems assist with data entry into the inventory system and warehouse setup for inbound items. Then, physical processing such as radio frequency ID tagging, barcode scanning, and other methods can assist in organizing the items for storage.

Additionally, several WMS platforms recognize and label every item as it is delivered.

Role of AI in Warehouse Management System Development

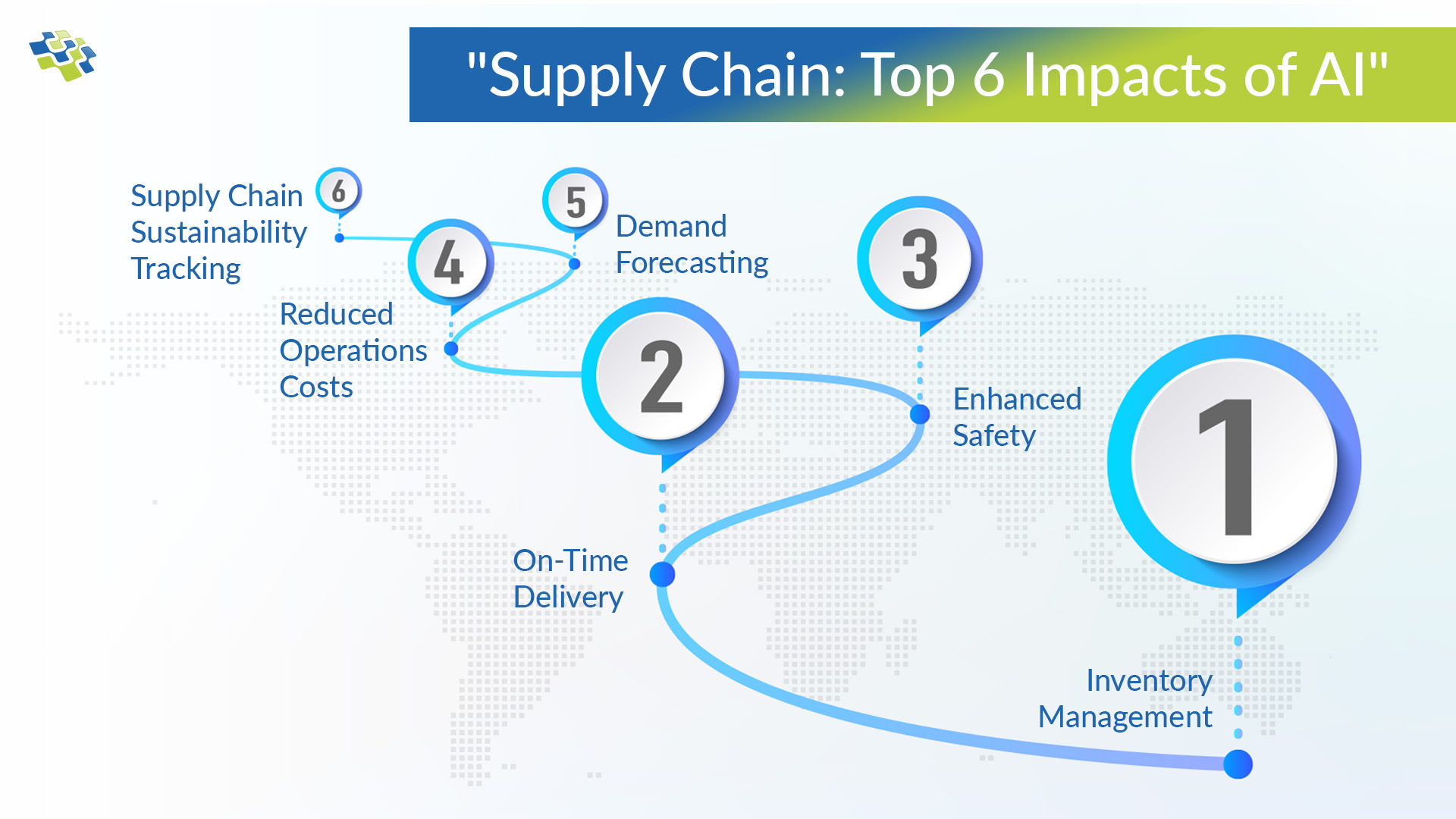

The integration of artificial intelligence in the supply chain sector is transforming the nature of warehouse operations, and businesses can leverage these developments to maintain a competitive edge. Every industry similarly uses AI, depending on data and analysis using algorithms.

- Warehouse management systems with AI-backed models integrated can evaluate massive volumes of data from various sources to spot trends, identify abnormalities, and forecast potential supply chain disruptions.

- The WMS can anticipate demand variations, optimize supply chain operations, and make well-informed decisions about procurement, transportation, and inventory management with their predictive capabilities.

- AI predictive maintenance can also be utilized to extend the life of the warehouse’s equipment and enhance overall performance.

- Warehouse operations can be greatly optimized by utilizing AI technologies to monitor equipment performance, which increases productivity and lowers expenses. Up to 10% less money can be spent on maintenance overall using a predictive maintenance program that uses AI.

Algorithms driven by AI improve order-picking routes by considering variables like product attributes, picking frequency, and order priorities in real-time. Warehouses can raise throughput, lower labor costs, and enhance order accuracy by strategically scheduling orders and optimizing travel routes.

Future of Warehouse Management System

Warehouse management systems have an exciting future ahead of them. This aspect of developing custom applications will be greatly impacted by technological developments like machine learning and artificial intelligence. AI and machine learning algorithms can also be used to improve the picking and packing process and forecast product demand. Additionally, businesses can utilize AI to automate repetitive jobs, freeing up warehouse employees to concentrate on higher-value and more difficult duties.

Therefore, it is fair to say that WMS has an exciting future ahead of it, with ongoing innovation and the use of new technologies boosting productivity, efficiency, and customer satisfaction.

How NextGen Invent Can Provide AI Assistance to Improve Your Logistics Management?

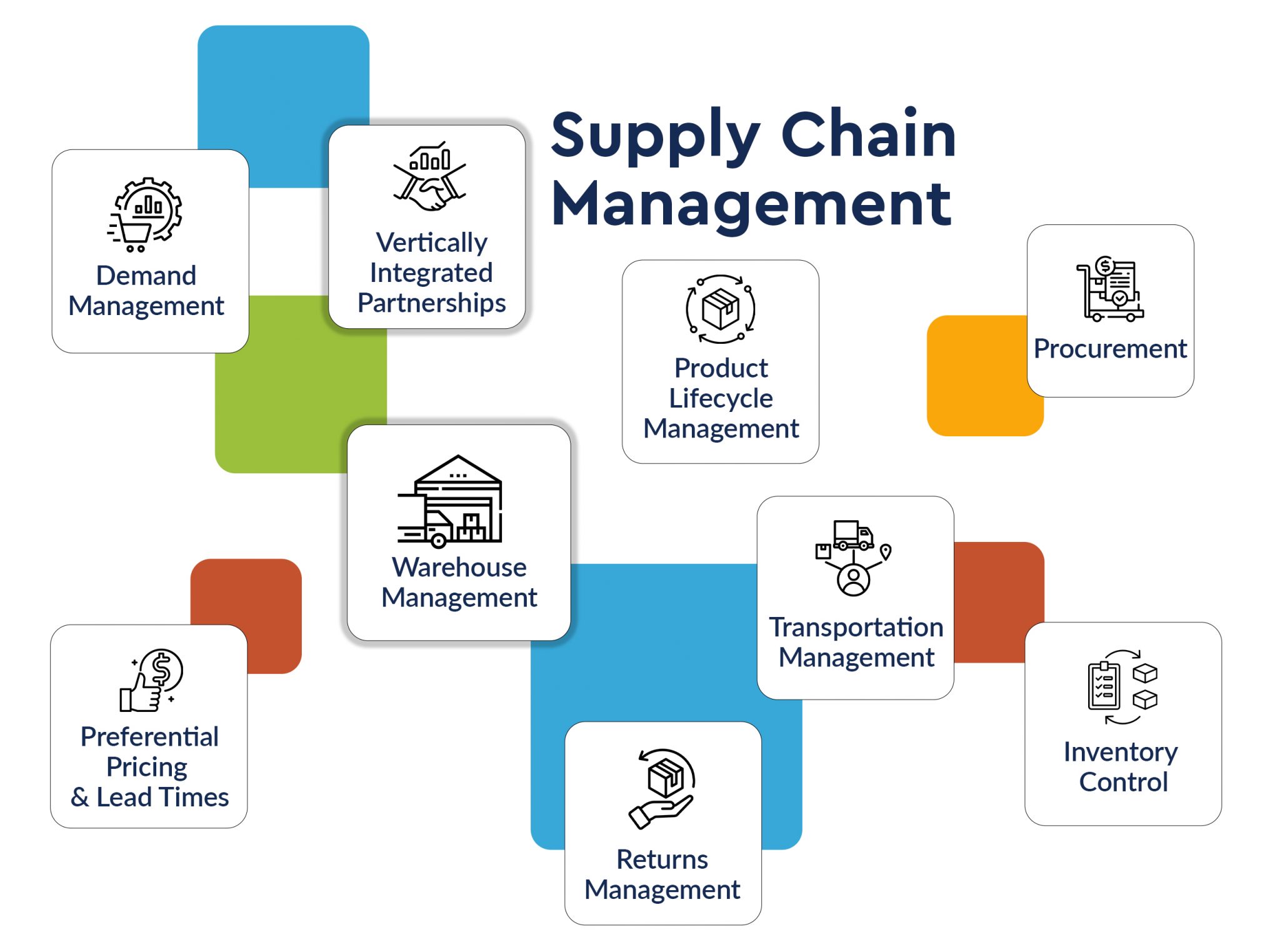

NextGen Invent’s AI-driven logistics and supply chain management solutions are tailored to optimize warehouse operations with a focus on productivity and cost-effectiveness. By providing real-time insights into all aspects of the warehouse process, from receiving to shipping, inventory management, and order fulfillment, it empowers employees to work more efficiently. The intuitive reporting feature offers easily understandable statistics and reports, enabling informed decision-making for short-term improvements and long-term strategic planning. Scalability is ensured, allowing businesses to adjust to market changes seamlessly. Ultimately, AI assistance enhances operational efficiency by improving speed, accuracy, and order fulfillment, leading to reduced costs and increased customer satisfaction.

With NextGen Invent as the leading supply chain software development company, businesses can stay competitive and adapt to evolving market conditions while achieving their goals of increased productivity and cost savings in warehouse management.

Ready to revolutionize your warehouse operations? Take advantage of NextGen Invent’s AI-powered logistics and supply chain management solution today. Contact us now!

Related Blogs

How AI Is Impacting Supply Chain Management?

Industry experts are certain that AI in supply chain management will “change the game”. It is rapidly emerging as a transformative technology, with the ability to process vast amounts of operational data generated by a range of sources, including cloud-based applications and sensors.

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then instantly evaluate the information to deliver insights.

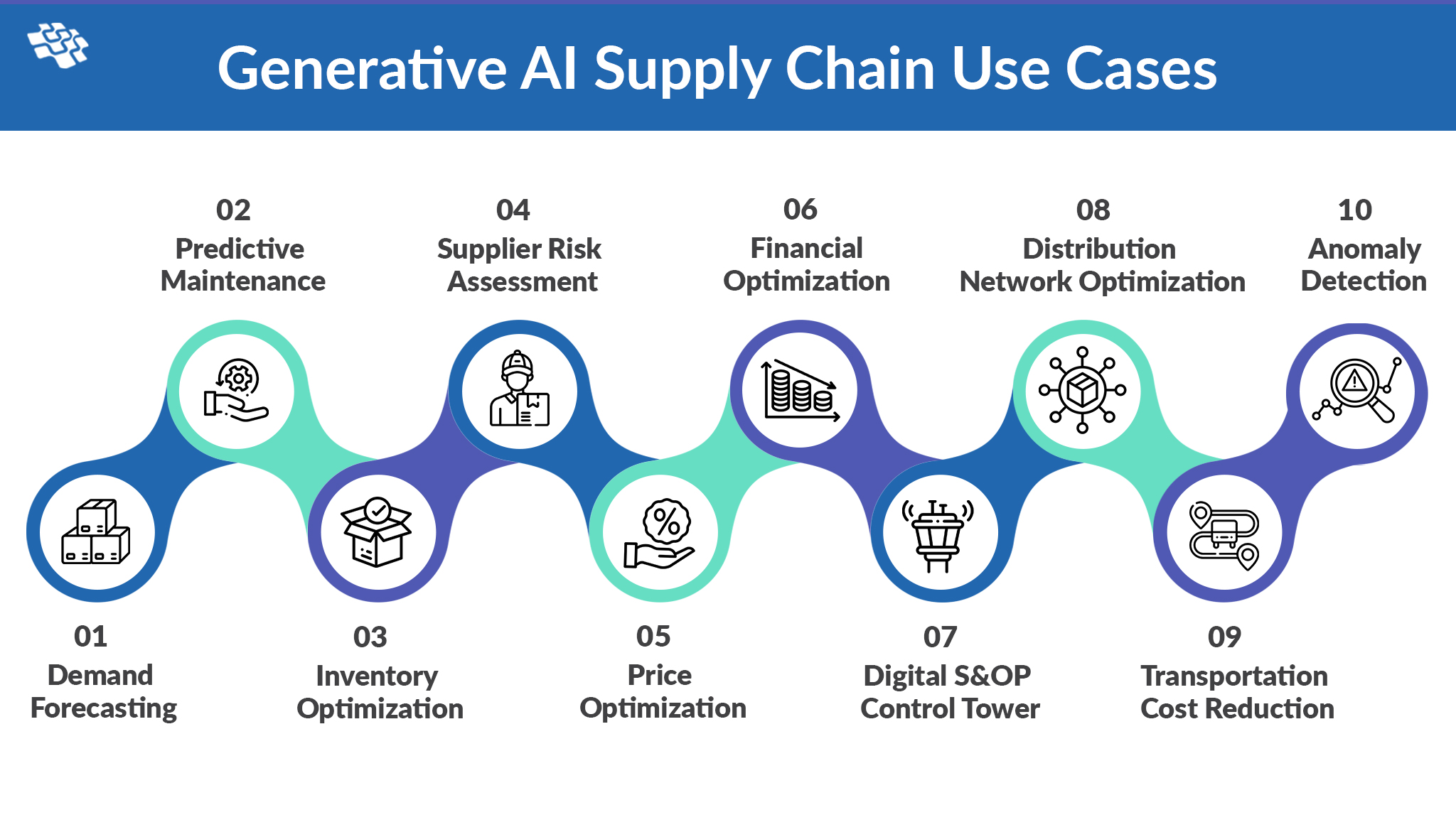

10 Most Crucial Use Cases of Generative AI in Supply Chain

AI integration has changed various industries recently, and the supply chain industry is no exception. The development of Generative AI has shown itself to be a revolutionary way to improve supply chain management.

Stay In the Know

Get Latest updates and industry insights every month.

1. Predictive Analysis

1. Predictive Analysis