How AI Drug Development Enhances Product Improvement Across the Drug Lifecycle

Pharmaceutical companies can accelerate processes, reduce expenses, and offer safer and more individualized drugs with the extra support of modern AI pharmacy management software services. This blog will delve into the importance of AI pharmaceutical product development, its important applications throughout the R&D pipeline, how it is transforming drug manufacturing, and product improvement across the drug lifecycle.

Too Many Failed Phase II Trials? Use Predictive Analytics to Validate Drug Efficacy Earlier

“Involvement of AI in the development of a pharmaceutical product from the bench to the bedside can be imagined, given that it can aid rational drug design; assist in decision making; determine the right therapy for a patient, including personalized medicines; and manage the clinical data generated and use it for future drug development.”– NCBI

Biotech Product Improvement with AI Drug Development

It might be difficult to improve a product once the drug has passed the rigorous process of clinical trials. Nevertheless, after a treatment has been approved, Post-Marketing Surveillance (PMS) can apply AI to enhance drug safety and efficacy monitoring and analysis. According to research, an AI system routinely performed better than manual searches in several diagnostic assays, with noticeably higher precision rates.

Another area where AI may make a big difference is in production scaling. AI can streamline every step of the production process, from procuring raw materials to packaging the finished product. Patterns in production data can be analyzed by machine learning algorithms to spot quality problems before they become product flaws. Higher product quality, less waste, and fewer operating expenses are all ensured by this proactive strategy.

AI systems, for example, can schedule maintenance during downtime, anticipate equipment failures before they occur, and ensure that gear runs within ideal bounds. AI predictive maintenance provides a steady supply of high-quality drugs and helps avoid expensive production halts.

Why Does Drug Development Take So Long? Understanding the 10–15 Year Pharma Timeline

Due to several operational, regulatory, and scientific challenges that ensure the efficacy and safety of novel drugs, traditional drug development is drawn out and dangerous. From early discovery through human proof-of-concept studies to regulatory approval, it takes an average of 10 to 15 years to bring a new medication to market, and this process costs more than $2.5 billion.

The high rate of attrition is among the biggest challenges.

Finding new drugs has proven incredibly ineffective.

- Only 10–20 of every 10,000 molecules evaluated move on to development, and only a small percentage of those ever make it to clinical trials.

- The actual clinical trials are difficult and time-consuming. With up to 50% of research locations enrolling one or no patients and approximately 80% of trials missing enrollment deadlines, patient recruiting is a significant difficulty.

- Additionally, studies show that about 90% of medical candidates don’t make it through the clinical development stage.

- Lack of clinical efficacy (40–50%), uncontrollable toxicity (30%), poor pharmacokinetic characteristics (10–15%), and insufficient commercial viability or strategic planning (10%) are the main causes of these failures.

Adjustments to trial procedures have also become more common due to their growing complexity. These adjustments are frequently required to accommodate changing scientific knowledge or legal constraints. These changes have the potential to raise expenses and create major delays.

Check our Case Study: From Months to Minutes: AI-Driven Ingredient Intelligence Revolutionizing OTC Drug Discovery

How AI Improved Efficiency, Quality, and Throughput in Pharmaceutical Manufacturing

The production procedure of a pharmaceutical manufacturing company was problematic in one case. Due to equipment failures and inefficiencies in their production process, they were having a lot of downtime. To solve these problems, they chose to use AI.

An AI-powered predictive maintenance solution was included in the business’s operations. By analyzing data from the machinery, this system was able to anticipate faults before they happened. Additionally, the system might recommend the best maintenance plans, cutting down on needless downtime and boosting overall production effectiveness.

The outcome was striking. Significant downtime reductions for the business resulted in higher output and significant cost savings.

Benefits of Using AI Drug Development & Production

AI has many advantages for the discovery and development of drugs.

- It can save researchers valuable time in the initial stages of research by analyzing enormous volumes of data to find possible therapeutic candidates. In the past, finding promising chemical compounds required researchers to spend endless hours reading scholarly publications and running tests. Scientists can concentrate on more difficult tasks by using AI to automate this process.

- Researchers can choose the most promising candidates for additional testing by using AI algorithms to anticipate the characteristics and behavior of these molecules. AI can provide information about the safety and effectiveness of medication candidates by examining molecular structures and historical experimental data. In addition to saving time, this lowers the possibility of choosing hazardous or useless chemicals for additional research.

- Automation and robotics driven by AI are increasing productivity, decreasing errors, and optimizing drug production. Pharmaceutical companies can increase production speed while upholding safety and quality standards by utilizing AI. AI can monitor and regulate production-related factors, including temperature, pressure, and mixing ratios, ensuring that every batch of medication meets the requirements.

In conclusion, the application of AI drug development and production offers several benefits, including the ability to predict compound attributes, identify potential therapeutic candidates more efficiently, and optimize manufacturing processes.

How AI is Transforming Drug Manufacturing?

Knowing how AI functions in the pharmaceutical sector can help businesses increase output by integrating more intelligent technologies into the production process. These technologies assist manufacturers in identifying issues early on, operating more effectively, and upholding the high standards of quality that patients rely on.

AI can expedite the delivery of novel therapies to patients in the following ways:

- Digital Twins: These intricate computer models replicate real manufacturing equipment, allowing businesses to test modifications and observe potential outcomes without endangering actual output.

- Inventory Management: AI studies supply chain trends and demand patterns to help businesses order the right quantity of resources at the right time.

- Predictive Maintenance: AI monitors data on the functioning of the equipment and alerts users when a machine needs maintenance, averting malfunctions that could stop production lines.

- Process Optimization: These systems evaluate hundreds of data points to improve the efficiency and consistency of the production process.

- Quality Control: AI-powered solutions are quicker and more accurate than conventional inspection techniques at identifying quality faults.

Long Trial Timelines Impacting ROI? Deploy AI-Based Clinical Decision Support Systems to Accelerate Execution

AI Drug Development Use Cases That Transform Product Improvement Across the Drug Lifecycle

AI is transforming drug development by driving measurable product improvement at every stage of the lifecycle. Below are the top five AI drug development use cases that accelerate discovery, optimize clinical trials, enhance decision-making, reduce risk, and deliver safer, more effective therapies faster.

1. AI-Driven Drug Discovery

1. AI-Driven Drug Discovery

By evaluating enormous datasets to find drug candidates, pharmaceutical AI is significantly enhancing the drug discovery process. The time and expense associated with conventional drug development techniques can be decreased by using machine learning models to anticipate how various chemicals interact with biological targets.

AI systems, for instance, can screen millions of molecules in silico to identify the most promising ones, which can then undergo additional laboratory testing.

2. Accelerating Clinical Trials & Predictive Modeling

Although they take a lot of time and money, clinical trials are an essential part of the drug development process. By optimizing patient recruitment, forecasting results, and spotting possible problems early on, AI can enhance this process. For example, AI can use patient data analysis to match people with appropriate clinical trials according to their medical history, genetic profiles, and other characteristics.

The area of predictive modeling is also having a significant impact. AI systems can forecast the safety and effectiveness of novel drugs by analyzing past data from studies and trials. As a result, researchers are better equipped to decide which drug possibilities to pursue, saving millions of dollars in development expenses and lowering the likelihood of failure later on.

3. Anomaly Detection & Digital Twin

Pharmaceutical companies can find and duplicate the “golden batch” that reduces deviations and rework by combining anomaly detection with digital twins, a state-of-the-art AI use case. Digital twins make use of past manufacturing data, such as machine settings, operator assignments, and environmental factors like temperature and humidity.

After identifying the golden batch, anomaly detection systems keep an eye out for deviations and send out notifications when something goes wrong, like a machine running at the wrong speed, so that remedial action may be performed right away. Consistent batch quality is ensured by this capacity. According to a McKinsey study, top-performing pharmaceutical manufacturers achieve only one-sixth of the deviations per 1,000 batches of their average competitors, which results in 14 times lower quality expenses than their peers.

4. Computer Vision-Driven Quality Checks

Real-time identification of scraps and units that need to be reworked is possible with AI-powered computer vision systems, allowing for prompt remedial action. Because of the industry’s strict cGMP regulations and top-notch production standards, maintaining consistent quality is crucial.

In addition to increasing labor productivity and freeing employees to work on higher-value tasks, this also helps track and enhance first-pass yield over time. Due to fewer flaws and more effective procedures, the final product is of greater quality and costs less.

5. Assist in Drug Quality Control

AI can examine drugs on a conveyor belt and identify flaws like broken packaging. Additionally, the technology analyzes industrial data, such as quality control tests, to detect any possible problems. Through sensors that assess vibration, temperature, sound, and other parameters, AI can keep an eye on production line equipment and spot flaws. This allows workers to repair the equipment before it malfunctions and stops producing.

Artificial intelligence is capable of analyzing data on energy consumption, raw material waste, and other variables, and making recommendations for improving the manufacturing process. The system’s ability to predict demand also helps pharmaceutical companies avoid producing large quantities of medications that will be squandered if they are not needed.

Manual Trial Monitoring Increasing Risk? Enable Real-Time Patient Tracking with AI And Wearable Integration

Key Challenges Hindering AI Adoption in the Pharmaceutical Industry

AI has enormous potential in the pharmaceutical sector, but to fully reap its rewards, many issues must be resolved. The availability of data is one major challenge. Large volumes of objective, high-quality data are necessary for AI models to work well, and pharmaceutical businesses frequently find it difficult to obtain or handle this data successfully. Challenges also arise from data privacy issues, particularly when handling private patient data.

The lack of transparency of AI algorithms is an additional issue. Many AI models, especially deep learning algorithms, function as “black boxes,” making it challenging to understand how they make specific decisions. Particularly in delicate domains like medication approval and patient safety, this lack of interpretability may erode confidence in AI-driven procedures.

- Bias in Data: Biases in training data can be inherited by AI models, resulting in inaccurate forecasts and judgments.

- Ethical Concerns: The ethical implications of machines making life-or-death decisions are brought up by the application of AI in drug research and patient care.

The Future of AI Drug Development & Pharmaceutical Innovation

It is anticipated that AI will become increasingly crucial to pharmaceutical innovation in the future. New technologies like AI-driven simulations, generative models, and reinforcement learning will improve the identification of new drugs and therapeutic modalities. Drug research will become more effective, collaborative, and accessible worldwide through integration with robotics, cloud computing, and real-time analytics.

A change toward data-driven pharmaceutical strategies, where decisions are made based on predicted insights rather than instinct or trial-and-error, will also result from AI. The development, testing, and delivery of healthcare solutions might be completely transformed by this paradigm, which would eventually help patients and healthcare systems around the globe.

How Can NextGen Invent Help You in Your AI Journey?

The pharmaceutical industry is entering a pivotal phase where artificial intelligence is no longer optional but essential for driving continuous product improvement across the drug lifecycle. From early drug discovery and preclinical research to clinical trials, regulatory approval, and post-market optimization, AI is transforming how data is analyzed, decisions are made, and risks are reduced.

Capabilities such as predictive modeling, real-world evidence analytics, and AI-based clinical decision support systems are enabling faster insights, improved trial outcomes, and more personalized therapies. As drug development becomes increasingly complex and data-intensive, organizations need a trusted partner to translate AI potential into real-world impact.

This is where NextGen Invent plays a critical role. NextGen Invent helps life sciences and pharmaceutical companies design, build, and scale end-to-end AI solutions, spanning drug discovery platforms, clinical trial optimization, and intelligent decision support systems. By combining deep domain expertise with advanced AI, data engineering, and cloud-native architectures, NextGen Invent empowers organizations to accelerate innovation, enhance product quality, and deliver better patient outcomes with confidence.

Frequently Asked Questions About AI Drug Development

Related Blogs

How AI in Drug Development is Transforming the Industry?

Drug development is one field with a lot of promise since it will gain from developments in the application of AI to forecast cellular disease processes, protein folding, and molecular interactions.

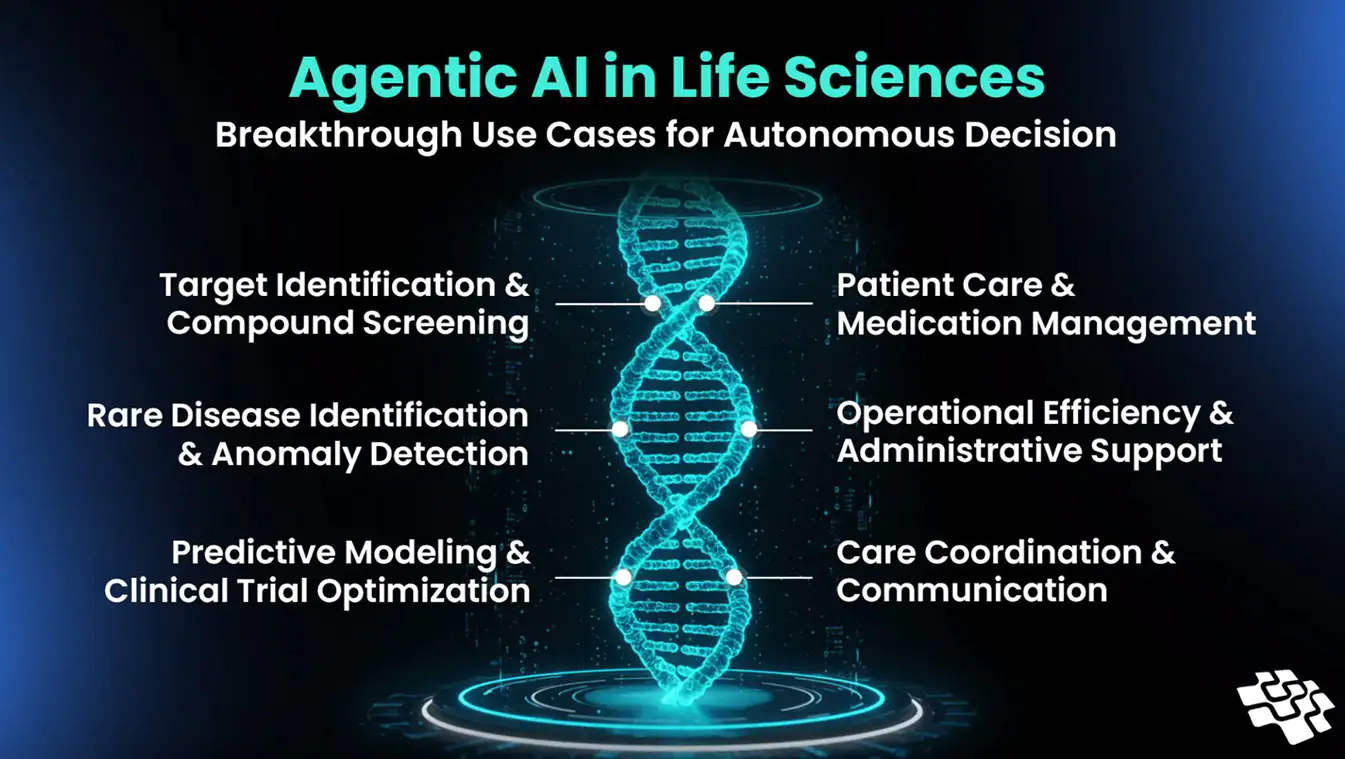

From Trial Delays to Smart Decisions: How Agentic AI In Life Sciences Is Redefining Innovation

Businesses in the life sciences are being compelled to adopt cutting-edge technologies like AI promptly due to mounting demands from R&D costs and increasingly complex regulations.

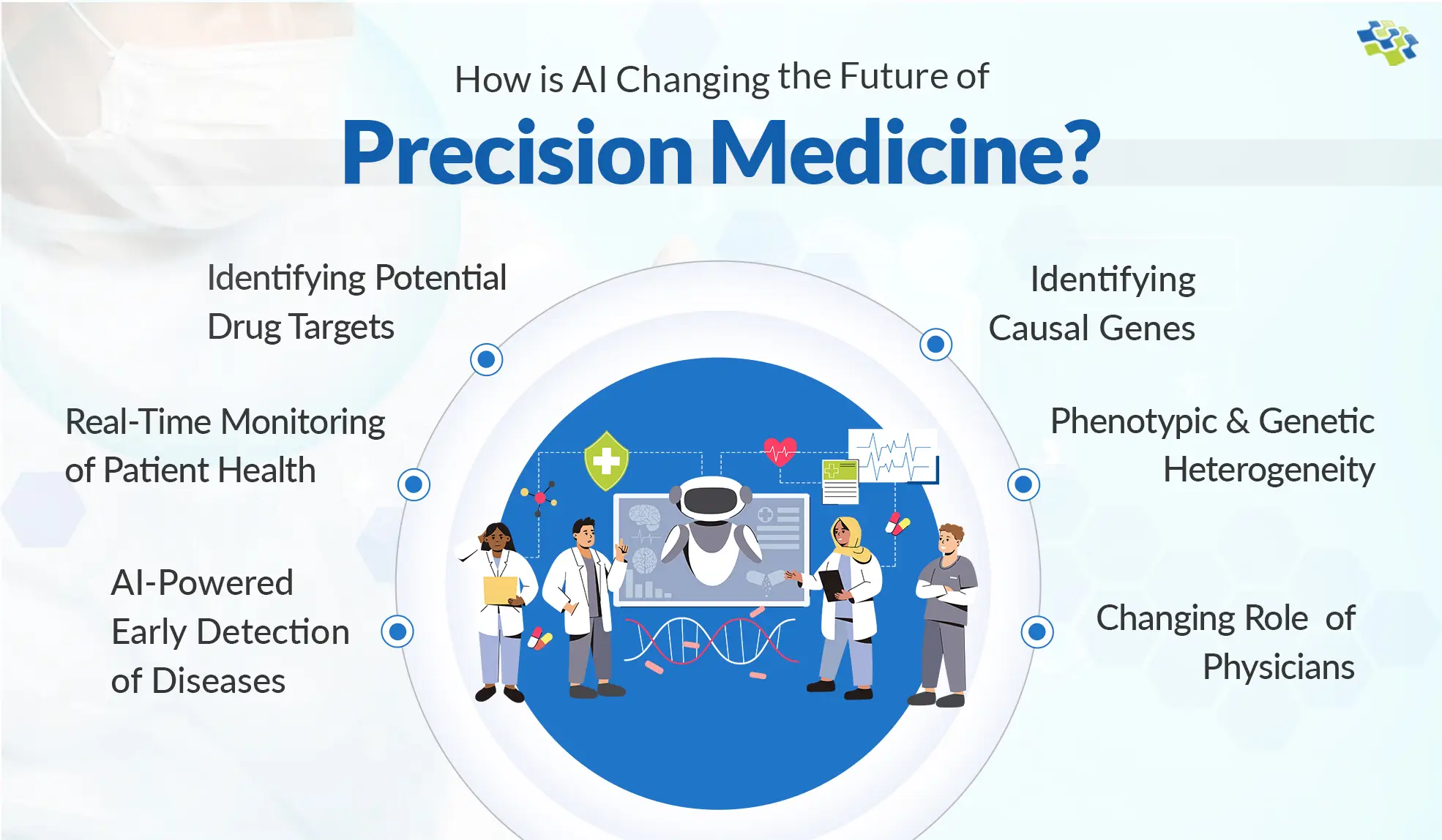

How is AI Changing the Future of Precision Medicine?

This evolution revolves around three core tenets: patient-centricity, the generation of vast data demanding sophisticated analytics, and the establishment of precision medicine as the new norm.

Stay In the Know

Get Latest updates and industry insights every month.

1. AI-Driven Drug Discovery

1. AI-Driven Drug Discovery