How AI in Inventory Management is Redefining Inventory Control?

However, 43% of small businesses do not keep an eye on their inventory, and only 6% of companies say they have complete supply chain visibility, which is necessary for efficient inventory management. As global inventory management in supply chain management networks becomes more complex and the need for disruption-immune operations becomes more pressing, supply chain executives are concluding that more stringent inventory control is essential if they want to keep increasing their margins and providing satisfying customer experiences.

Tired Of Stockouts? Harness AI To Optimize Inventory with Our Expert AI Data Scientists!

“AI in inventory management can significantly improve operational efficiency, reduce costs, and enhance the overall customer shopping experience with retail stores. For instance, in January 2024, according to the National Association of Convenience Stores, a US-based trade association, the number of convenience stores operating in the United States until 2024 had risen to 152,396, reflecting a 1.5% growth compared to the previous year’s count.”– The Business Research Company

The Role of AI in Inventory Management

Businesses are always searching for methods to enhance their operations and obtain a competitive advantage. In this endeavor, artificial intelligence has become a potent partner, providing innovative solutions to enduring inventory management challenges. Instead of being a single, monolithic technology, artificial intelligence is a range of skills that allow machines to simulate human intelligence, such as task automation, prediction, and data-driven learning.

AI in inventory management can improve it in many ways, from automated decision-making to real-time data analysis. This technology is a vital tool for inventory optimization since it can process enormous volumes of data quickly, precisely, and without strain. Numerous industries, including manufacturing, logistics, supply chain, and e-commerce, can benefit from the development of warehouse inventory management system software:

- Supply Chain: AI in supply chain management assists in forecasting customer demand, enabling businesses to keep the right amount of inventory on hand and prevent overstock or stockouts.

- Logistics: AI can expedite route optimization, resulting in timely deliveries and cost savings.

- Manufacturing: AI can improve production planning through component and raw material supply optimization.

How Can AI Help Traditional Inventory Management Systems Overcome Its Challenges?

To overcome the difficulties and complexities that traditional inventory management systems encounter, artificial intelligence is essential. Here are some ways AI helps with each of these issues:

- Inaccurate Demand Forecasting: Traditional inventory management systems frequently make inaccurate predictions about future demand patterns because they rely on previous data and crude demand forecasting techniques. Issues with overstocking or understocking can arise from this. AI analyzes large datasets, including past sales data, market trends, and outside influences, using complex algorithms and machine learning approaches. It can increase the accuracy of demand forecasting and lower the risk of overstocking or understocking by spotting intricate patterns and connections.

- Difficulty in Demand Planning: It could be difficult for traditional systems to consider variables like market trends, outside influences, and shifting consumer behavior beyond historical sales data. Demand planning uses a variety of AI-integrated aspects, such as market trends, historical data, and outside impacts. AI offers more precise and detailed demand projections by utilizing complex forecasting models and predictive analytics, which helps companies better estimate future demand and adjust inventory levels appropriately.

- Inefficient Order Fulfillment:Traditional methods may result in effective order fulfillment procedures, postponed shipments, and unhappy customers due to their real-time visibility into inventory levels. AI streamlines order fulfillment procedures by prioritizing orders according to availability and urgency, optimizing routes, and dynamically distributing inventories. By improving customer happiness and offering real-time insights into inventory levels and order status, artificial intelligence optimizes order fulfillment procedures.

- Supply Chain Disruptions:Unexpected supply chain interruptions, like delays in production or delivery, can be difficult for traditional systems to manage and might affect the inventory management procedure. AI-powered predictive analytics can foresee supply chain interruptions and proactively reduce risks. Artificial intelligence uses past data and outside variables to find vulnerabilities in supply chains and suggest backup plans to reduce interruptions.

AI in Inventory Management: Benefits

With the advent of AI, inventory management has entered a new era of precision and effectiveness. This technology is a revolutionary force that is changing how businesses handle their inventory; it is more than just a tool. AI is transforming the difficulties of inventory management into chances for development and innovation by automating intricate procedures, offering perceptive analytics, and facilitating real-time decision-making. However, what precisely are these benefits that artificial intelligence offers? To better comprehend, let’s examine a few of them:

- Data Structuring & Analysis: Dealing with unstructured and disorganized data is one of the major problems that businesses encounter. This data can be cleaned up and organized by AI, which will improve its suitability for analysis, executive debriefs, and visualizations. This helps businesses make better decisions by improving the quality of insights obtained from the data. AI turns data into a potent instrument that can propel business expansion and strategic decision-making.

- Increased Efficiency: Data gathering, analysis, and even reordering procedures are just a few of the inventory management tasks that AI can automate. This automation increases overall productivity by giving employees more time to concentrate on other important aspects of the company. AI increases the effectiveness of inventory management by removing manual chores and lowering the possibility of human error.

- Cost-Effectiveness: Businesses can save a significant amount of money by using AI to improve accuracy and efficiency. Reduced storage costs, less waste from overstocking, and more revenues due to accurate forecasting can all contribute to a healthier bottom line. This cost-effectiveness can give organizations a significant advantage in a competitive business environment, allowing them to devote more resources to expansion and innovation.

- Improved Accuracy: The accuracy with which AI algorithms can interpret data is significantly higher than that of human analysts. The risk of overstocking or understocking is decreased by more accurate inventory projections. Businesses can prevent running out of goods or spending money on unnecessary storage by using AI to maintain ideal inventory levels. This degree of precision is especially helpful in the fast-paced commercial world of today, where even a minor error in judgment can have serious consequences.

Improve Supply Chain Efficiency Through Advanced AI Inventory Management Software Tailored to Your Needs!

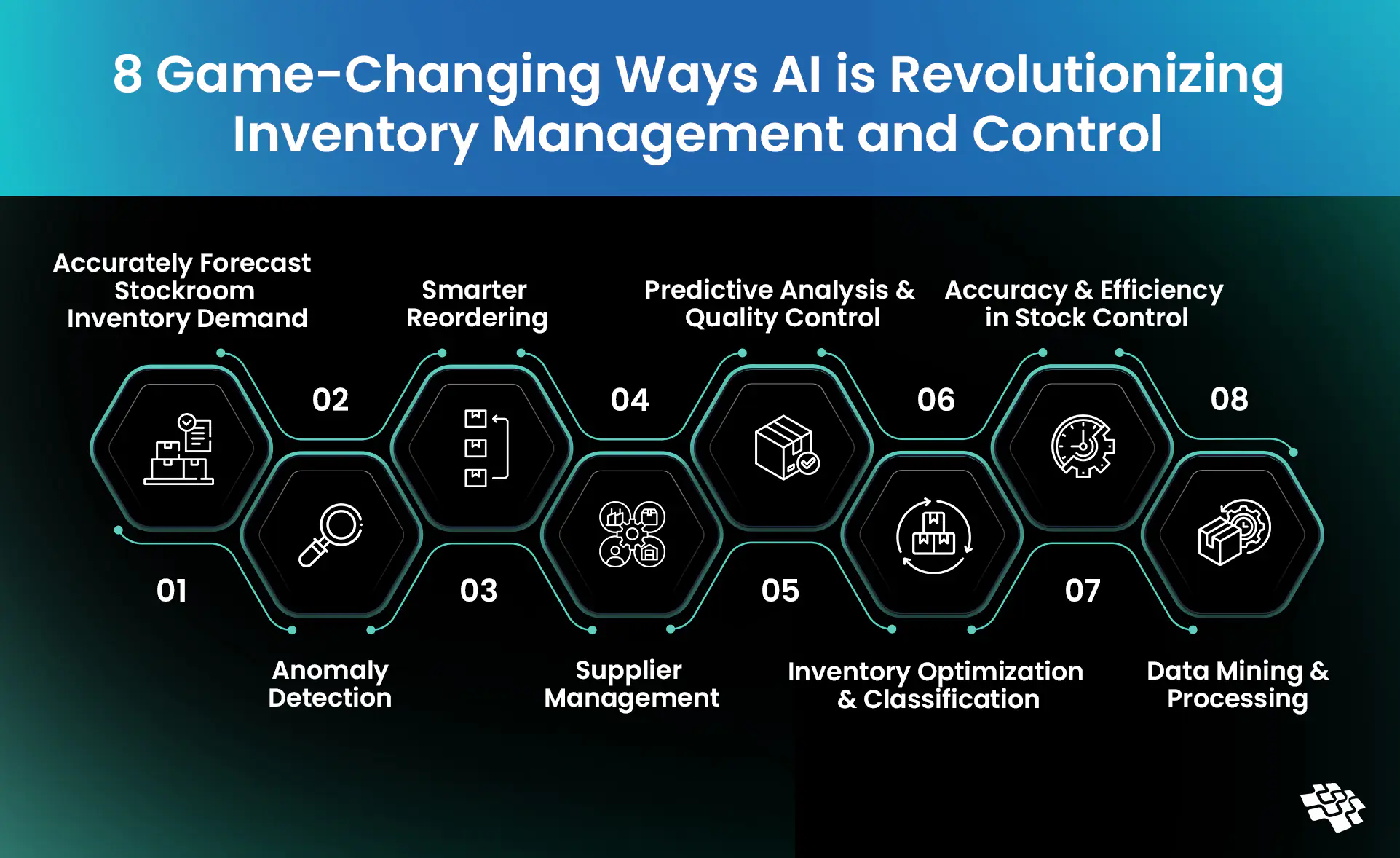

Top 8 Ways AI in Inventory Management is Redefining Inventory Control

AI technologies can completely transform how businesses manage inventories by streamlining procedures, reducing expenses, and increasing effectiveness. This shift is expected to affect small manufacturers, distributors, and substantial businesses. Here are a few use cases of AI in inventory management. Supply chain managers have already started implementing some of these.

1. Forecast Stockroom Inventory Demand

1. Forecast Stockroom Inventory Demand

One of the most complex yet crucial parts of inventory management is demand forecasting. Demand forecasts in the past were based on past orders, but they don’t consider stockroom inventory utilization and often result in overordering or stockout issues. AI now can produce more accurate results if you feed it high-quality use data. The capacity of AI to use consumption data from your stockroom’s automated inventory management system to spot trends in inventory utilization and suggest ideal minimum and maximum levels that specify what and when to refill is an interesting use of AI in inventory management.

AI in stockroom inventory, for instance, provides the best minimum and maximum levels for every inventory item based on real-time data, historical usage from the point of use, days needed for replenishment, and average daily usage. More impressively, it determines and shows the amount of inventory and carrying cost savings you could get by switching to optimum levels.

2. Anomaly Detection

AI can be used to identify anomalies in sales trends or inventory levels. Large data sets can be processed using machine learning algorithms to identify outliers. These irregularities could be signs of problems like vandalism, mistakes, interruptions, or changes in demand in the future.

Businesses can respond swiftly to issues because of this detection capacity, preserving inventory integrity and operating effectiveness.

3. Smarter Reordering

It’s a science and an art to know just how much inventory to order. After all, effective reordering necessitates a thorough grasp of not only the inventory that is now available but also its potential expiration or obsolescence dates, storage locations, geographies of demand, supplier fulfillment times for new orders, and much more.

Although there are now several best practices for maintaining strict inventory control, experts predict that artificial intelligence will further simplify reordering. Businesses using AI for inventory management in supply chain management will be able to place orders with greater assurance than ever before since AI can seamlessly couple various data points (such as safety stock, reorder point, and lead time) with all technical inputs and weigh them against cash flow and demand projections.

4. Supplier Management

AI can use previous data to examine supplier performance. It helps with the objective selection of the best option, even though most buyers are aware of the advantages and disadvantages of their suppliers. AI systems examine past data from numerous vendor transactions. Consider the following two situations: Vendor A exhibits both sporadic delays and on-time deliveries. A variety of passed products are displayed in the quality control, along with some rejected things. In general, Vendor A’s delivery and quality control practices are both dependable and erratic. Conversely, Vendor B frequently encounters delays in the delivery of the goods. Delays might be anything from two to four days. Vendor B’s quality control includes both rejected and passed items.

Although there are sporadic quality problems, this research suggests that Vendor A generally does better in terms of on-time delivery and quality control. Conversely, Vendor B frequently has delays and could need to enhance its delivery capabilities. To reduce rejected items, both sellers could profit from paying more attention to quality control.

5. Predictive Analysis & Quality Control

AI systems can predict maintenance requirements and identify quality problems by analyzing sensor data from production machinery and storage facilities. Businesses can prevent expensive production delays, minimize downtime, and proactively schedule maintenance by anticipating equipment breakdowns or product flaws. By anticipating failure rates and ensuring the availability of essential parts, predictive maintenance can also maximize the inventory of spare parts.

Through the analysis of data from testing, inspections, and customer feedback, AI can also improve quality control procedures. AI algorithms can identify quality problems and departures from expected norms through machine vision, picture recognition, and natural language processing. Businesses can improve overall accuracy, reduce the likelihood that faulty items will reach customers, and efficiently eliminate human error by automating quality control procedures.

6. Inventory Optimization & Classification

It can be difficult to manage a diversified product portfolio, especially when there are thousands or even millions of stock-keeping units (SKUs) involved. Products can be categorized and segmented by AI algorithms according to several factors, including seasonality, profitability, sales velocity, and demand patterns. Businesses can strategically focus their inventory management efforts on high-value or quickly moving items by categorizing their inventory. Effective resource allocation and inventory control strategy optimization are made possible by this method.

Furthermore, by considering variables like lead time, required service levels, and demand variability, AI-driven optimization algorithms help determine the ideal safety stock levels for every product. Businesses can make data-driven decisions about product selection and cross-selling opportunities by using AI algorithms to uncover product alternatives or complimentary items based on market trends and previous sales data.

7. Accuracy & Efficiency in Stock Control

Improving stock control accuracy and efficiency is one of AI’s main use cases for inventory management. AI systems can automatically reorder products or modify stock allocations by analyzing real-time data, including sales, returns, and inventory levels. Retailers can reduce human error and ensure ideal inventory levels by automating these procedures. AI can also assist in making the stocktaking process more efficient. In the past, keeping inventory required manual counting and recording, which was labor-intensive and prone to mistakes. Supply chain managers can use AI to automate the stocktaking process by utilizing technologies like computer vision and barcode scanning. It can swiftly recognize and record inventory items without the need for human intervention, which not only saves time but also increases accuracy.

AI also improves stock control accuracy by lowering the possibility of stock inconsistencies. To make sure that there are no differences between the recorded stock and the actual stock, AI algorithms can continuously check inventory levels and compare them to sales data. This helps retailers avoid losses from supply differences by quickly identifying and resolving any issues.

8. Data Mining & Processing

AI transforms inventory management in data mining by examining historical and current data, improving precision, and extracting valuable information from massive datasets.

Through stock maintenance and surplus inventory reduction, this proactive approach optimizes supply chain effectiveness. By identifying trends in customer behavior, AI-driven data mining assists businesses in aligning their inventory with market demands. Additionally, it makes decision-making easier by providing useful information for adjustments.

Reduce Operational Costs by Implementing Smart Inventory Control with Our AI-Driven Development Services!

Cost of AI Inventory Management Software Development

The cost of developing AI-powered inventory management software depends on various factors, including its features, scalability, and level of customization. Key components like machine learning algorithms, predictive analytics, and real-time data processing play a significant role in determining the investment required. Development time, integration with existing systems, and the need for advanced functionalities such as demand forecasting, automated reordering, and inventory optimization also influence costs. Moreover, industries with complex supply chains can require more advanced software solutions, which can impact the overall development effort.

| Development Type | Estimated Cost | Timeline |

| Simple | $20,000 – $40,000 | 2- 4 Months |

| Medium | $40,000 – $80,000 | 4 – 6 Months |

| Advanced | $80,000 – $120,000 | 9+ Months |

Careful planning, clear objectives, and a phased development approach can help businesses achieve maximum value, ensuring a strong return on investment.

The Future of AI in Inventory Management

Even more advanced inventory management applications are anticipated as AI technology develops further. Companies like Amazon are leading the way in the development of automated warehouses and robots driven by AI.

Future developments in computer vision, machine learning, and predictive analytics will further simplify inventory procedures, giving businesses more accuracy, efficiency, and flexibility.

AI-Driven Inventory Optimization with NextGen Invent

As we’ve seen, the integration of AI into inventory management has ushered in a new era of business effectiveness and optimization. Businesses can now increase customer service, stock management, and operational efficiency by utilizing chatbots, which are simple to incorporate into intelligent inventory management systems.

As a leading warehouse inventory management system software development company, NextGen Invent offers supply chain businesses cutting-edge AI development services for inventory and profit optimization. We develop custom AI software that simplifies daily operations and protects businesses from unforeseen disruptions with their extensive continuous simulative capabilities and real-time monitoring for a wide variety of variables.

Need Better Health Monitoring? Transform Outcomes with Our AI Healthcare Mobile App Development Services

Frequently Asked Questions About

Related Blogs

AI in Supply Chain: Embracing Future with Gen AI & Automation

In a recent interview, NextGen Invent took a significant step in reimagining the supply chain industry through modern technologies.

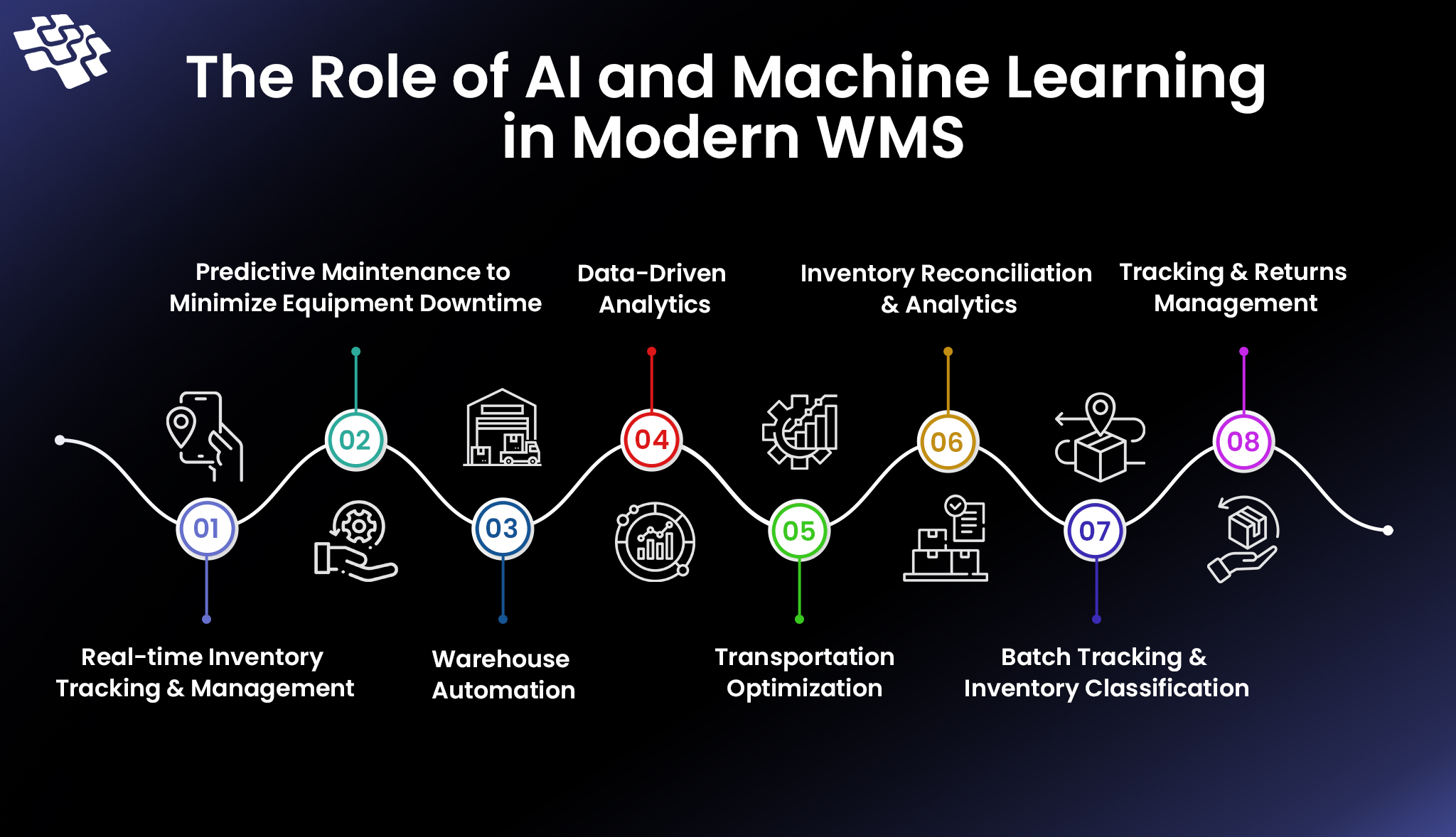

The Role of AI and Machine Learning in Warehouse Management

Warehouse management plays a significant role in supply chain operations. It ensures that goods are delivered, tracked, stored, and arranged as efficiently as possible.

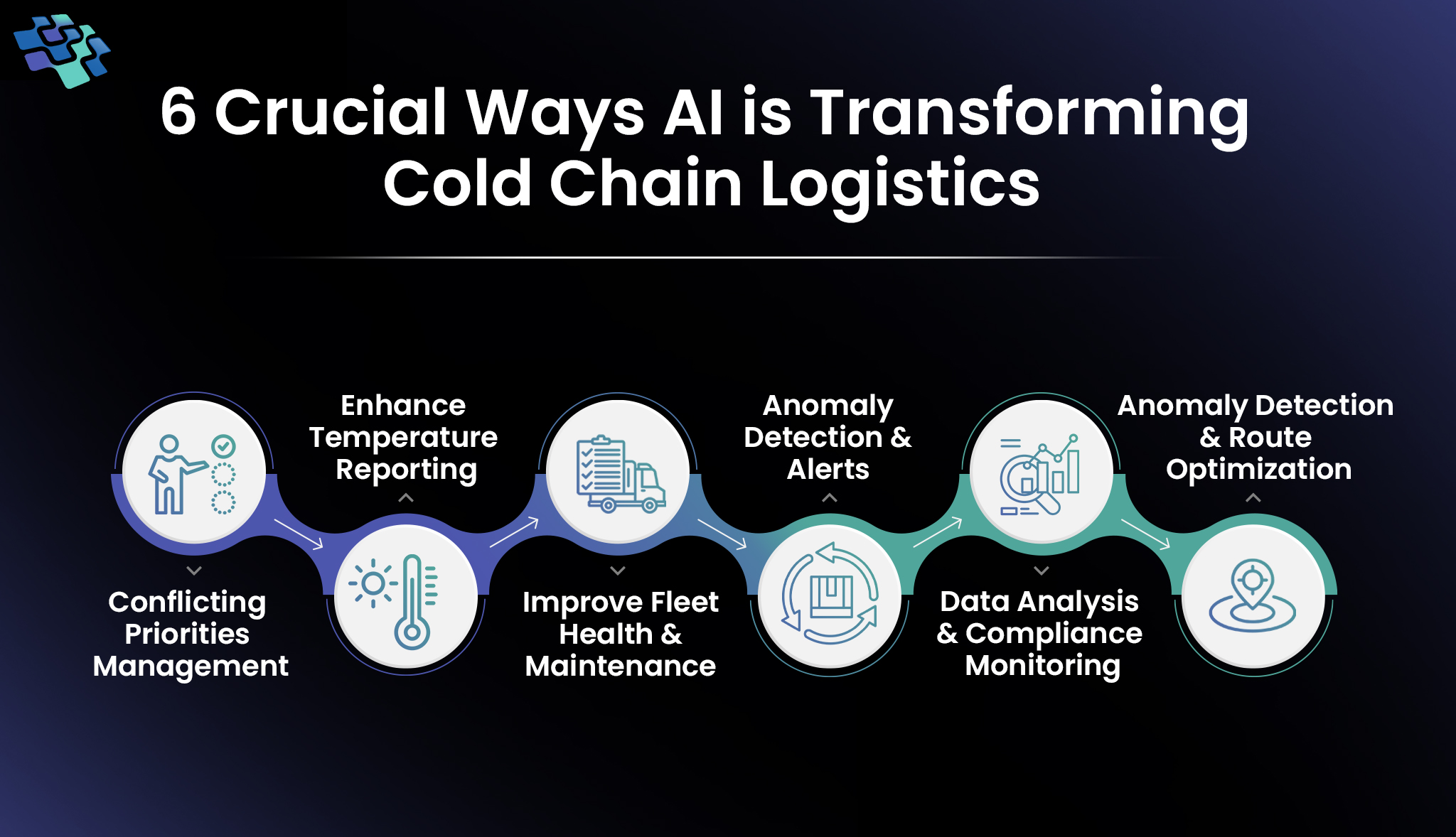

How Artificial Intelligence is Transforming Cold Chain Logistics?

Enhancing the cold chain logistics is essential for delivering today’s biotherapies. Drug items with controlled temperatures require care and attention throughout travel, regardless of their value, fragility, or difficulty in obtaining.

Stay In the Know

Get Latest updates and industry insights every month.

1. Forecast Stockroom Inventory Demand

1. Forecast Stockroom Inventory Demand