The Role of AI and Machine Learning in Warehouse Management

It facilitates inventory management, demand forecasting, work automation, and layout optimization. Additionally, it can enhance the quality control procedure, order fulfillment, and logistics. We’ll look at how AI is changing warehouse management in this blog. We will study artificial intelligence, its applications in warehousing, and its advantages.

Battling Warehouse Inefficiencies? Leverage AI To Optimize Space, Reduce Costs, And Improve Flow

“In the quest for greater resilience, companies are now looking for ways to boost the speed, reliability, flexibility, and productivity of their warehouse and distribution operations. Automation has emerged as the answer. It promises to help organizations tackle pressing supply chain problems: addressing labor challenges, improving fulfillment quality and safety, maximizing space utilization, and increasing throughput.”– Mckinsey

How is AI Changing Warehouse Management?

Have you ever wondered why online orders can be completed so quickly?

The answer is found in complex warehouse management that combines artificial intelligence. Over time, warehouse management has evolved from manual inventory tracking and paper-based procedures to more contemporary electronic approaches. Due to the increase in e-commerce and delivery speeds, purchases must be delivered more quickly. Warehouse managers can more readily streamline processes with the use of modern solutions.

From streamlining inventory control to enhancing packaging and picking procedures, artificial intelligence has fundamentally changed warehouse operations.

Is AI Disrupting the Logistics & Warehouse Industry?

AI is presently climbing the Peak of Inflated Expectations in logistics, and like most disruptive technologies, its rate of innovation is outpacing the market’s capacity to adopt it. This is particularly valid in logistics. A supply chain has numerous moving technology components, such as partner integrations and warehouse management.

Being a beta user of dazzling, generative AI technologies is also met with a fair bit of industry cynicism, particularly if the company developing the technology has the logistical know-how to support its marketing claims. Understanding the best chances for innovation requires hard-won knowledge because warehouse management and logistics operations can be extremely complex and subtle.

Benefits of AI in Warehouse Inventory Management

There are numerous advantages to using AI in inventory management, which not only improve operational efficiency but also affects a company’s financial performance. Let’s take a closer look at these.

- Cost Reduction: The potential for large cost savings is one of the strongest arguments for companies to use AI in inventory management. AI-driven inventory optimization makes sure companies have the proper amount of goods on hand, which reduces holding costs. Stockouts and overstocking are expensive issues that AI can help with. Businesses can increase profitability, lower storage costs, and more efficiently manage resources when inventory levels are optimized.

- Inventory Accuracy and Reduction in Errors: When applied appropriately, AI solutions are incredibly accurate and dependable, which lowers the error margin in inventory management. In addition to minimizing data input errors and minimizing mismatches between recorded and physical inventory, this accuracy translates into exact product tracking.

- Efficient Resource Allocation: Businesses can more effectively use their human resources by using AI to automate repetitive inventory processes like placing and reordering orders. While AI manages the daily inventory operations, staff members may concentrate on strategic tasks like marketing, supplier negotiations, and customer support.

Experiencing Delays in Order Fulfillment? Our AI Solutions Streamline Processes and Boost Efficiency

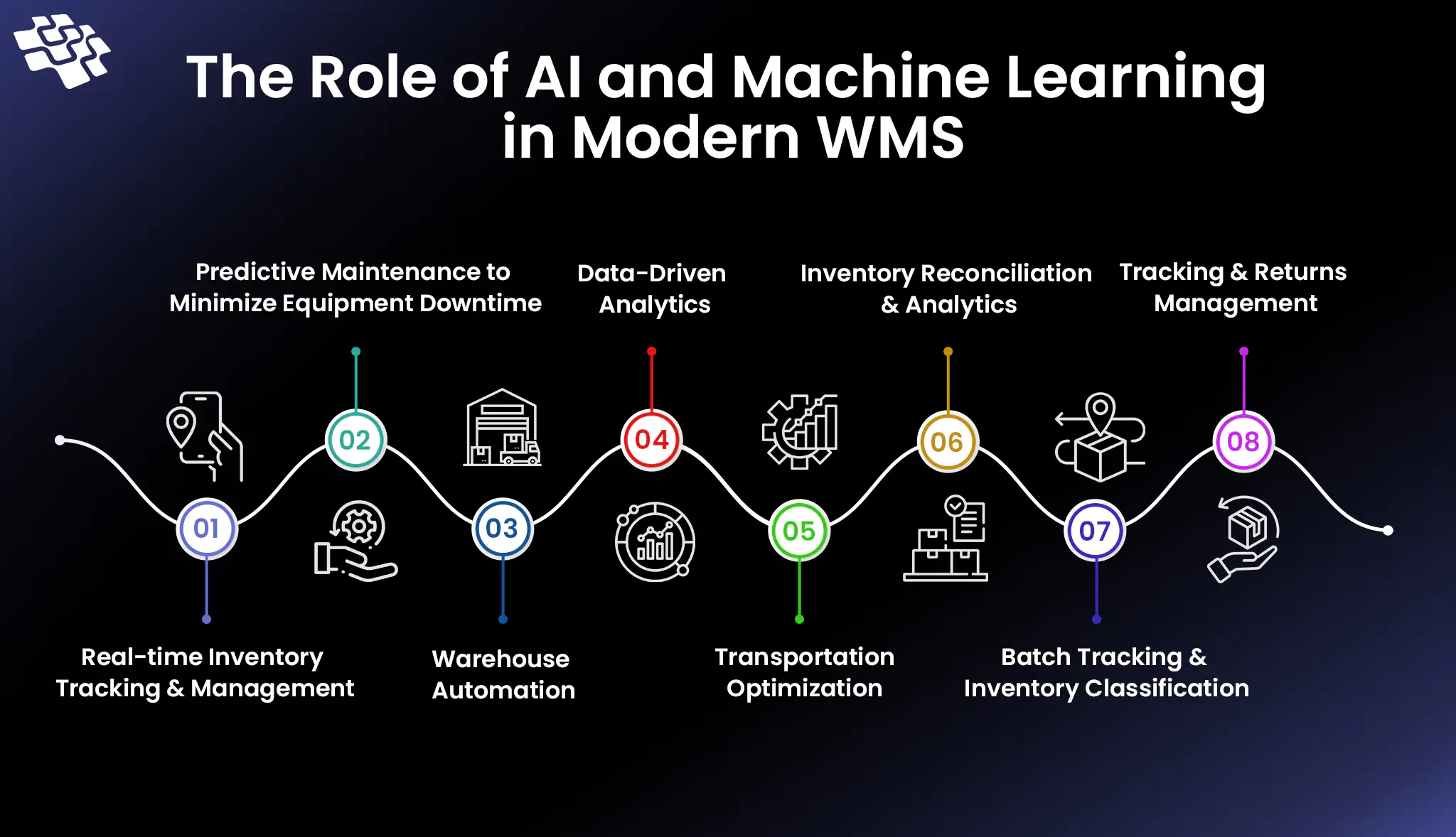

The Role of Machine Learning & AI in Warehouse Management

AI’s capacity to streamline processes is revolutionizing warehouse management. Here’s how.

1. Real-time Inventory Tracking & Management

1. Real-time Inventory Tracking & Management

With the aid of artificial intelligence, modern inventory management enables accurate tracking and management by giving real-time visibility into inventory levels.

The system can detect low stock levels, forecast demand fluctuations, and optimize replenishment strategies by utilizing technologies such as the Internet of Things and evaluating data from multiple sources, including cameras, RFID, and barcode tags. This helps to reduce stockouts and optimize storage space.

2. Predictive Maintenance to Minimize Equipment Downtime

Monitoring machinery, a vital resource that warehouses cannot function without, is one of AI’s predictive skills. AI can continuously analyze data from IoT sensors and equipment to spot anomalies and predict impending failures, but broken conveyors and forklifts frequently result in considerable costs and delays.

With that information, businesses can preventative maintenance during off-peak times when operations won’t be significantly disrupted.

3. Warehouse Automation

74% of supply chain executives are boosting their technology investments, with 90% stating they will spend more than $1 million, MHI Annual Industry Report. A substantial portion of those expenditures will be used for automation solutions driven by AI, including warehouse robotics.

The market for warehouse robots is expanding as businesses invest in products that assist people in picking, sorting, moving, and storing parcels. Human workers can be replaced by these robots. However, they typically take over monotonous jobs to free up staff members for more important work.

Demystify AI and Automation for Supply Chain

4. Data-Driven Analytics

There is always some inherent risk and unpredictability in logistics and warehousing. Organizations must prepare for every situation to ensure resilience in the face of these conceivable threats. Risk management has become essential in the face of worldwide canal obstructions, pandemics, economic downturns, and significant supply chain disruptions. By simulating various situations, AI risk management solutions can assist firms in improving their planning. Predictive analytics solutions, for instance, can forecast variables like inventory, supply and demand, warehouse space, truck driver capacity, and more by analyzing historical data and applying statistical models.

Dynamic pricing, in which product prices fluctuate based on supply and demand, is another application of AI. By adapting more quickly to current market conditions, this enables organizations to be more competitive.

5. Transportation Optimization

Transportation optimization is one area of logistics where AI really shines. For instance, by evaluating capacity statistics, weather reports, traffic data, real-time RFID tracking data, and other information, AI may be used to determine the optimum shipping routes each time.

AI-powered route optimization enables logistics firms to ensure quicker delivery, which reduces expenses and maintains client satisfaction. Additionally, it lowers the amount of fuel and driving hours required to transport the same goods.

6. Inventory Reconciliation & Analytics

Employing automated reconciliation, AI seamlessly integrates returned items with inventory records, promptly updating stock levels and initiating restocking or disposal procedures, as necessary. By maintaining precise inventory records, AI provides businesses with a comprehensive overview of their inventory status, enabling informed decision-making regarding future inventory management strategies. This capability enhances operational efficiency, minimizes discrepancies, and optimizes inventory control processes for sustained business success.

To inform future inventory management strategies and decision-making, AI examines inventory data to identify trends, patterns, and optimization opportunities. AI enables businesses to improve their inventory management procedures and adjust to changing market conditions by providing actionable insights and suggestions.

7. Batch Tracking & Inventory Classification

Businesses can carefully monitor and trace inventory batches across the whole supply chain by using AI-powered monitoring solutions. Improved inventory management is made possible by this thorough visibility, which guarantees ideal stock levels and effective resource allocation. Additionally, by precisely recording inventory movement and storage conditions, AI makes regulatory compliance easier. AI makes it easier to respond quickly and precisely to recalls or quality problems, reducing customer impact and successfully reducing corporate risks.

Better organization and administration are made possible by AI’s ability to automatically classify inventory goods according to a variety of criteria, including size, weight, and demand trends. This automation ensures effective handling of a variety of inventory by streamlining management and organization procedures. Businesses may maximize storage, expedite retrieval procedures, and make well-informed judgments about inventory replenishment and allocation by precisely classifying goods.

8. Tracking & Returns Management

Using real-time tracking capabilities, AI tracks inventory movements along the delivery process, providing insight into the location and status of shipments. AI reduces the possibility of stockouts and overstocking and enables precise delivery by continuously monitoring inventory levels across various supply chain stages. This proactive strategy makes sure inventory levels match demand at every stage of the supply chain, which improves operational effectiveness and customer happiness.

AI analyzes return trends and causes expedites the processing of returns, identifying patterns in customer preferences, supply chain inefficiencies, and product flaws. AI minimizes the effect of returns on inventory levels and maximizes recovery value by automating the processing of returns and restocking choices. Businesses may effectively handle returns, raise customer happiness, and boost inventory management procedures with this proactive strategy.

Facing Inventory Challenges? Transform Your Warehouse with Our AI Supply Chain Management Solutions

Challenges of Implementing AI in Warehouse Management

Despite its numerous benefits, integrating AI in warehouse management is not without challenges:

- Complex Integration: It can be difficult from a technological standpoint to integrate AI with current warehouse management and other systems. Maintaining operational continuity requires that AI and older systems communicate with each other seamlessly.

- High Initial Costs: AI technology implementation necessitates a large initial hardware, software, and infrastructure investment. Additionally, there are expenses related to educating employees on how to effectively use modern technology.

- Workforce Adaptation: The role of human employees in the warehouse will change as AI replaces repetitive labor. To ensure that staff members can collaborate with AI systems efficiently, this calls for a change in the organization’s culture as well as investments in training and skill development.

The Future is Now: Embracing AI in Warehousing

The development of AI technology is inextricably related to the future of warehousing. AI’s uses in warehouse management will grow as it develops further, spurring additional innovations and efficiencies. The following patterns demonstrate the path that AI-driven warehousing is taking:

- Personalized Customer Experiences: AI will make it possible to create supply chain solutions that are more dynamic and tailored to the tastes and habits of specific customers.

- Continuous Learning & Improvement: The efficiency and productivity of warehouses will continuously increase as AI systems’ capacity to make precise predictions and judgments improves with the amount of data they collect.

- Enhanced Integration with IoT: With sensors and smart devices supplying real-time data that AI systems may utilize to further optimize warehouse operations, the Internet of Things and AI are expected to become increasingly entwined.

- Sustainability: AI-driven warehouse operations optimization will be essential to minimizing environmental impact, cutting waste, and developing more sustainable logistics methods.

Conclusion

In summary, the incorporation of AI into warehouse management ushers in a new era of logistics that offers previously unheard-of levels of accuracy, resilience, and efficiency. AI improves operational optimization, safety, and predictive analytics with innovative technology like robotics, computer vision, and machine learning, resulting in supply chains that are agile and sustainable.

Strategic deployments highlight AI’s critical role in influencing future warehousing operations, despite adoption obstacles such as technological integration, cost, and staff reskilling. Crucial factors for a successful integration are as follows:

- To facilitate the adoption of AI, interoperability and user-friendly interfaces should be prioritized.

- Combining the development of technology with moral principles and human-centered methods.

In addition to streamlining warehouse operations, this evolution reinterprets the role of the workforce by prioritizing collaborative human-AI models and upskilling. The emphasis on sustainability, efficiency, and resilience will propel additional AI integration as the sector develops, highlighting the technology’s pivotal role in supply chain management and warehousing in the future.

NextGen Invent, a leading AI Based Software Development Services Company, is transforming supply chain management with innovative AI-driven solutions. Our developed solutions enhance demand forecasting, optimize inventory, and provide real-time insights, allowing businesses to reduce costs and streamline operations. By automating complex workflows and empowering data-driven decisions, NextGen Invent’s AI solutions are designed to help companies overcome supply chain challenges and achieve sustainable growth. Contact us today to discover how we can enhance your supply chain management.

Frequently Asked Questions About Machine Learning & AI in Warehouse Management

Related Blogs

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently.

Everything Businesses Need to Know About Warehouse Management Systems

Warehouse and distribution tasks need to be optimized, monitored, and managed by any large, complex logistics or supply chain company.

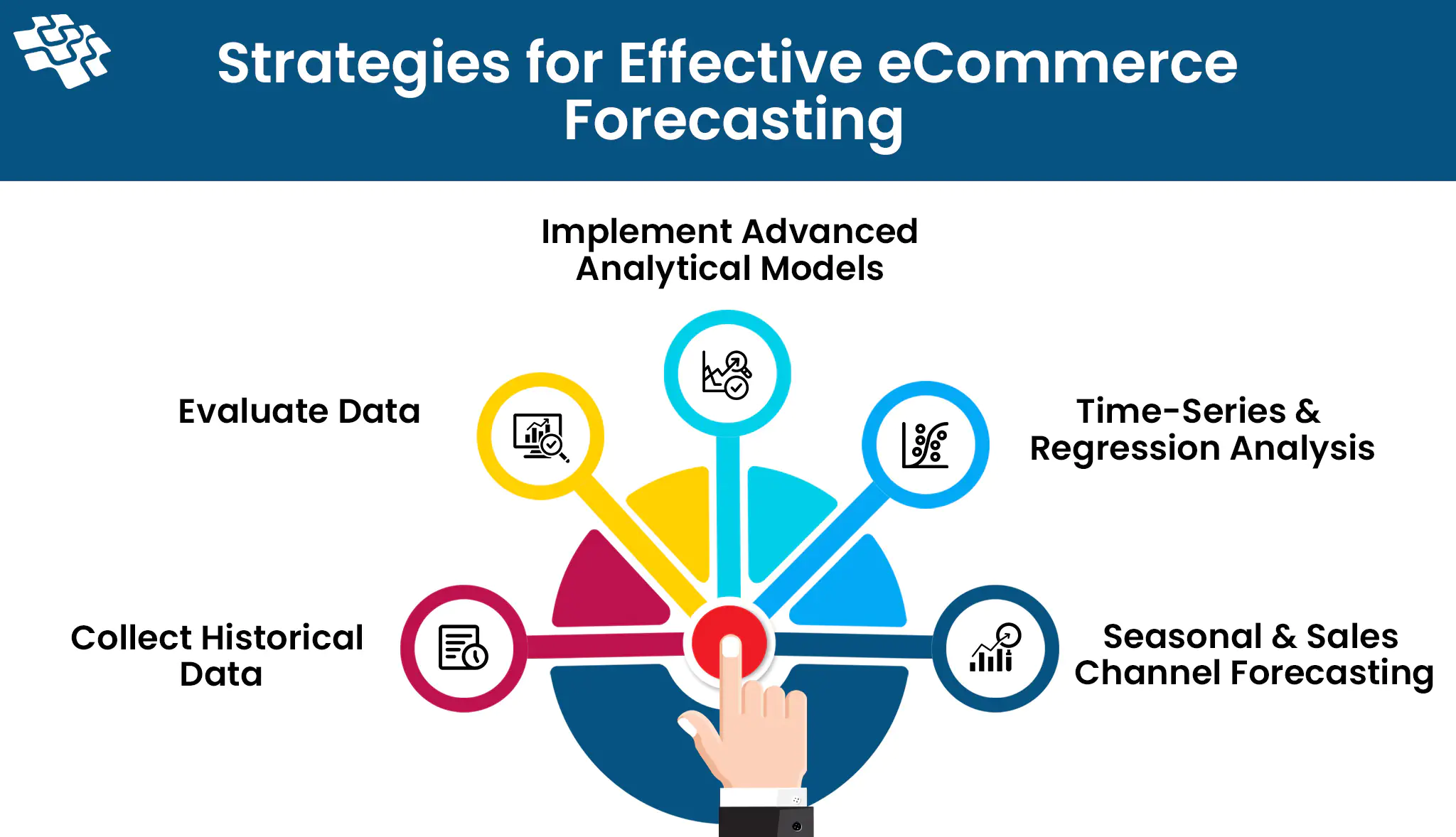

How to Win at Ecommerce Demand Forecasting in 2024

People aren’t machines. They don’t always behave in the same ways, which can cause problems for an eCommerce business. For instance, a product that did well in sales the previous month may collect dust in a warehouse.

Stay In the Know

Get Latest updates and industry insights every month.

1. Real-time Inventory Tracking & Management

1. Real-time Inventory Tracking & Management