Agentic AI in Manufacturing: How Smart Autonomy Reduces Downtime and Improves Workplace Safety

It could significantly outperform the current state of basic AI programming by making strategic judgments, resolving issues, and maintaining production efficiency. Half of the leaders are interested in exploring multi-agent systems (45%) and agentic AI (52%).

Cut Energy Costs Through Digital Twin Simulations That Optimize Consumption Without Additional Capital Investments

“By 2028, 33% of enterprise software applications will include agentic AI, up from less than 1% in 2024, enabling 15% of day-to-day work decisions to be made autonomously.”– Gartner

Agentic AI in Manufacturing: Hype Cycle or Lasting Value?

The use of agentic AI in manufacturing is much more than a fad. Aiming for operational excellence, staying resilient, and achieving sustained success in the current competitive environment are rapidly becoming company necessities. Businesses that prioritize AI-driven technology are known to consistently outperform the competition.

Today’s manufacturers are under tremendous pressure to increase product quality, enhance manufacturing processes, and reduce costs. Without constant human oversight, agentic AI meets these needs by identifying inefficiencies, proactively resolving operational disruptions, and optimizing resources.

Businesses can respond swiftly to shifts in demand, shifts in the market, and unforeseen circumstances because of the technology’s real-time adaptation and ability to learn from new data.

How Does Agentic AI in Manufacturing Work?

- Data Collection: Industrial lines and machinery provide real-time data that sensors and IoT devices gather. The environment and machine performance characteristics are among the elements that characterize the manufacturing process.

- Data Analysis: Agentic AI in manufacturing can identify inefficiencies or problems before they become unmanageable because analytical models are based on current data.

- Decision Making: AI agents foresee and intentionally aid in the articulation of results obtained from the data to develop solutions for problems within an enterprise.

- Execution: Self-executing systems execute agentic AI decisions, enabling effective and feasible operation.

How Agentic AI in Manufacturing Differs from Traditional AI & Automation

Traditional manufacturing automation is built on fixed, rule-based systems made for repetitive processes like packing, material handling, and assembly. Despite their dependability, these systems are rigid; operator intervention is necessary for any change from the norm. This was enhanced by traditional AI, which used machine learning models to introduce data-driven insights.

Despite supporting applications like quality control and predictive maintenance, these systems are static and need human supervision and retraining. They are unable to act independently or adjust to the dynamics of production in real time, but they can use historical production data to help make decisions.

By allowing intelligent, autonomous systems to sense their surroundings, make judgments on their own, and adjust in real time without human input, agentic AI in manufacturing represents a huge advancement. Agentic AI, as opposed to traditional AI, continually optimizes processes using digital twins, computer vision, and real-time sensor data through the application of reinforcement learning and context-aware reasoning.

It facilitates dynamic goal setting throughout the supply chain, boosting operating efficiency, optimizing production schedules, and reducing downtime. Agentic AI turns manufacturing into a genuinely intelligent and adaptive system with features like self-learning optimization and multi-agent collaboration.

Why Leading Manufacturers Are Accelerating Investments in Agentic AI

Agentic AI is attracting a lot of investment from smart manufacturing companies for the straightforward reason that it yields quantifiable and quick results. Businesses using AI-driven technology have seen increases in process efficiency and a decrease in operational expenses, as was previously indicated.

This is a strategic decision focused on long-term business profitability and resilience, not merely technology advancement. The following factors are contributing to manufacturing leaders’ growing recognition of the benefits of agentic AI:

- Proactive Maintenance: Agentic AI improves overall production dependability by anticipating equipment faults and reducing unplanned downtime using predictive maintenance AI software solutions.

- Improved Operational Efficiency: By proactively managing inventory, locating bottlenecks, and allocating resources optimally, autonomous systems drastically cut waste and boost output.

- Enhanced Decision-Making: Businesses may make data-driven decisions faster and without human intervention with the aid of real-time analytics and predictive insights from agentic AI.

Unlocking Efficiency and Safety: Benefits of Agentic AI in Manufacturing

There are numerous significant benefits to incorporating agentic AI into manufacturing processes, including:

1. Improved Customer Satisfaction & Brand Loyalty

Production cycles are accelerated with agentic AI, allowing products to reach the market sooner. Market agility and competitiveness are increased by reactivity.

Up to 30% more operational efficiency can be achieved by implementing agentic AI technologies.

2. Reduced Administrative Time & Improved Customer Services

Agentic AI improves product quality and boosts customer satisfaction by reducing defect rates through advanced quality management.

Using AI in manufacturing can save processing times by as much as 40%. AI’s ability to swiftly identify and eliminate faulty products is frequently linked to better quality control.

3. Allow Humans to do Critical Thinking for Complex Work

In complicated and changing contexts, agentic AI is excellent at making quick, well-informed decisions. Without human involvement, it processes vast amounts of real-time data, ensuring quick and efficient reactions to shifting circumstances.

AI-enabled predictive maintenance could save unexpected downtime by 45% and maintenance costs by up to 30%.

4. Reduced Legal Expenses

Agentic AI enables early detection and mitigation of risks across production, supply chains, and maintenance, minimizing operational disruptions.

By preventing compliance breaches and contractual disputes, it helps organizations cut legal expenses by up to 30%. This results in smoother operations and stronger bottom-line protection.

5. Build Integrity of the Company & Customer Loyalty

By automating decision-making, manufacturers reduce human errors and biases, ensuring consistent, objective outcomes.

This reliability builds the company’s integrity, strengthens trust, and fosters long-term customer loyalty, key factors in maintaining competitive advantage and sustainable growth.

Reduce Manufacturing Inefficiencies with Agentic AI Services That Automate Processes and Optimize Resource Utilization

From Manual to Autonomous: Agentic AI Use Cases in Manufacturing

Agentic AI use cases in manufacturing demonstrate how the technology is evolving beyond analytics to actively optimize daily operations. Real-world applications validate their theoretical benefits, revolutionizing production efficiency, supply chain resilience, and predictive maintenance across modern manufacturing ecosystems.

1. Predictive Maintenance & Asset Optimization

1. Predictive Maintenance & Asset Optimization

In manufacturing, predictive maintenance is the most popular use of agentic AI. Both reactive (repairing equipment after it breaks) and preventive (planned maintenance regardless of condition) maintenance strategies were used in the past. With the use of agentic AI, predictive maintenance can:

- Use IoT sensors to continuously check the performance of your equipment.

- Detect minute patterns that point to possible problems before they happen.

- Suggest the best time for maintenance to reduce interruptions.

- Maintenance tasks are automatically scheduled according to production demands.

According to studies, AI-powered predictive maintenance methods can extend equipment life by 20–40% and decrease downtime by up to 50%.

2. Product Quality Control & Defect Detection

Traditionally, human inspection and sample techniques, both prone to mistakes and inconsistency, have been the mainstay of quality assurance. Quality control is revolutionized by agentic AI systems through:

- Using computer vision to monitor 100% of manufacturing in real time.

- Analysis of the root causes that connect flaws to process variables.

- Automatic modification of manufacturing parameters to preserve quality.

The outcomes of these qualities are exceptional. Manufacturers who use AI-based quality control systems report 30–90% reductions in defects, depending on the application and industry.

3. AI-Powered Production Efficiency

Agentic AI in manufacturing can automate crucial tasks like real-time production metrics monitoring, equipment failure prediction, and resource allocation optimization to maximize production efficiency. AI can help manufacturers find operational inefficiencies, reduce downtime, and enhance resource use by integrating with IoT systems.

- Autonomous agents identify inefficiencies or production bottlenecks by analyzing machine performance, resource consumption, and real-time production parameters.

- Agents can, for example, reallocate resources in response to changing demand or automatically schedule repair when equipment exhibits indications of underperformance.

Agentic AI gives manufacturers the capability to optimize operations, increase throughput, and cut costs by enabling autonomous process adjustments. This improves accuracy and ensures long-term operational success.

4. Ensuring Compliance with Intelligent Systems

For regulatory compliance and brand reputation, quality control compliance is essential. Through real-time data, predictive analytics, and autonomous decision-making, Agentic AI automation revolutionizes this process by maximizing quality, minimizing errors, and ensuring ongoing compliance.

Autonomous agents can be used to ensure consistent quality standards by leveraging real-time data from sensors, production lines, and consumer feedback. When manufacturing processes fluctuate, agents can independently detect and handle quality discrepancies while maintaining compliance.

The capacity for learning and prediction is where autonomous agents truly shine. Agents foresee failures of trends that could affect quality by analyzing both historical and current data. Agentic AI can, for instance, anticipate how a malfunctioning part of equipment will affect the quality of the final product and take preventative action to minimize downtime and preserve operational effectiveness.

5. Autonomous Robotics & Collaborative Systems

Traditional industrial robots depend on rigid programming and controlled settings, restricting adaptability. Agentic AI transforms robotics by creating systems that perceive environments, learn continuously, and adjust seamlessly to new situations, reducing human intervention while enhancing flexibility, efficiency, and reliability in manufacturing.

In modern agentic AI manufacturing facilities, AI-powered collaborative robots are rapidly gaining adoption. These advanced systems work safely alongside humans, managing repetitive or strenuous tasks while seamlessly adapting to evolving production needs. Real-world implementations show efficiency gains of up to 35% in assembly workflows and reductions of 22% in material waste, enhancing both productivity and reliability across manufacturing operations.

6. Self-Optimizing Production Lines & Supply Chains

Production lines equipped with agentic AI can dynamically adjust to changing circumstances, variations in demand, and resource availability. These systems optimize throughput and efficiency by continuously analyzing market signals, production data, and operational restrictions.

- Dynamic assembly task rerouting during equipment downtime.

- Real-time robotic trajectory adjustment for precision welding.

- Adaptive energy optimization aligned with utility price fluctuations.

Agentic AI systems also independently anticipate interruptions, negotiate with suppliers, and optimize logistics with supply chain optimization software.

The AI bots lower inventory holding costs by almost 20% and speed up response times by autonomously making supply chain decisions based on changing demand signals.

Improve Workplace Safety by Deploying Intelligent Systems That Predict Risks and Prevent Accidents Before They Happen

The Road Ahead for Agentic AI in Manufacturing: Future Aspect

Manufacturing is on the verge of undergoing several revolutions due to agentic AI. Industry adoption increases and technology advances; manufacturing processes will experience significant changes. By 2034, factories may achieve a 40% increase in operational efficiency and a substantial reduction in labor costs, thanks to agentic AI, according to research.

What can leaders anticipate for the next decade in terms of Agentic AI?

- Advanced Factory Autonomy: Agentic AI is expected to advance to the point where it can autonomously adjust to the demands of the market in real time and handle whole manufacturing lines with little assistance from humans.

- Better Human-AI Collaboration: Future factory floors will depend on how well human workers and self-governing AI agents coordinate. AI will take care of monotonous tasks, freeing up human teams to focus on high-value and innovative projects.

- Enhanced Sustainability and Circular Economy: By optimizing resource utilization, intelligent AI agents will significantly reduce waste and energy consumption. Manufacturers can become leaders in the sustainable industry and drastically lower their carbon footprints by utilizing agentic AI.

Agentic AI is poised to become a crucial competitive advantage in the future, revolutionizing the manufacturing sector with unmatched efficiency, sustainability, and inventiveness.

Key Trends of Agentic AI in Manufacturing

- Hyper-automation & Smart Manufacturing 2.0: Autonomous AI agents function as cognitive collaborators integrated into manufacturing environments in Smart Manufacturing 2.0. These days, agents manage entire production lines, learning, adapting, and making goal-aligned decisions in real time in addition to carrying out preset instructions. This reduces downtime and increases throughput by 20–30% by converting static automation into adaptive autonomy.

- Digital Twins Reinvented with Interactive Agent Layers: Digital twins were models, either static or reactive, that were used for monitoring or planning. Multi-agent systems are now used to power digital twins, which are dynamic, adaptable environments. New speed, safety, adaptability, and creativity thresholds will be unlocked by manufacturers who integrate these agentic frameworks into their fundamental processes.

- Predictive to Prescriptive Maintenance: Engineers are notified when anomalies are detected via predictive maintenance systems. To recommend fixes and start preventive measures, agents use sensor data, maintenance logs, and failure simulations. Optimizes asset life cycles, gets rid of reactive maintenance, and cuts downtime by 50%.

Conclusion

Businesses looking to stay competitive as the manufacturing sector develops are discovering that using agentic AI in manufacturing is strategically crucial. Companies that use intelligent, self-governing agents are already seeing impressive increases in productivity, improved quality control, lower expenses, and more efficiency.

Agentic AI will be the most significant development of the upcoming decade, placing early adopters at the forefront of environmental sustainability, operational efficiency, and creativity. Manufacturers who put off using agentic AI run the risk of losing out on chances for growth and profitability.

Are you ready to transform your manufacturing procedures? Let’s discuss if you’re prepared to boost safety, increase yield, and decrease downtime with autonomous agents. Schedule a roadmap meeting with our experts to learn more about how our Agentic AI-powered artificial Intelligence software development services can improve industrial processes.

Manufacturing is changing. With NextGen Invent, you can take the lead.

Frequently Asked Questions About Agentic AI in Manufacturing

Related Blogs

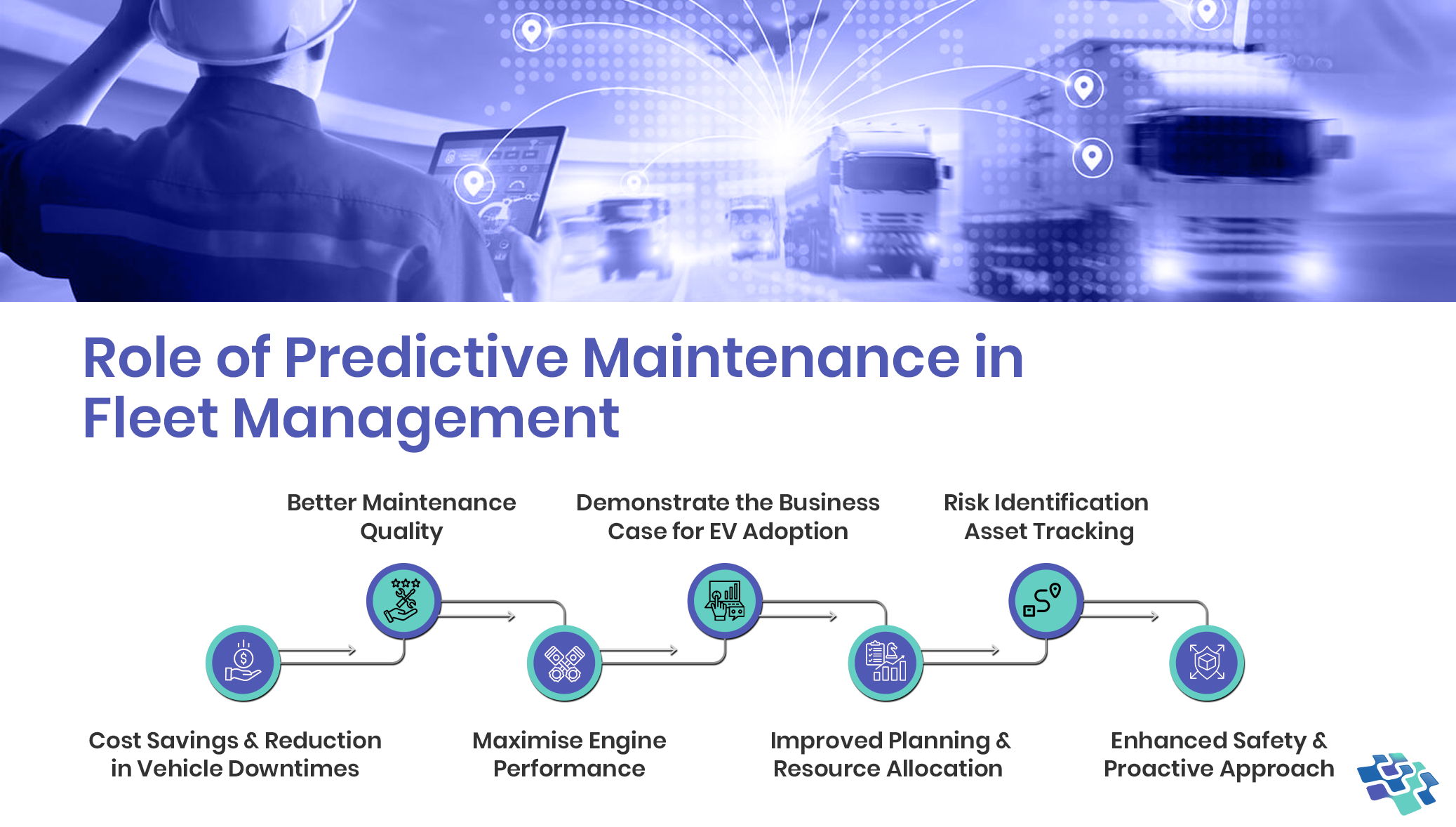

How Fleets Can Maximize Uptime and Efficiency with Predictive Maintenance?

Predictive maintenance has become a game-changing strategy among the numerous others that are accessible. Predictive maintenance has been shown to, boost vehicle availability by 20% , lower maintenance costs by up to 25%...

AI in Supply Chain: Embracing Future with Gen AI & Automation

Integrating Gen AI, automation, and AI in supply chain is a transformative force. These technologies offer a shift in how supply chains operate, providing avenues for enhanced efficiency, agility, and adaptability.

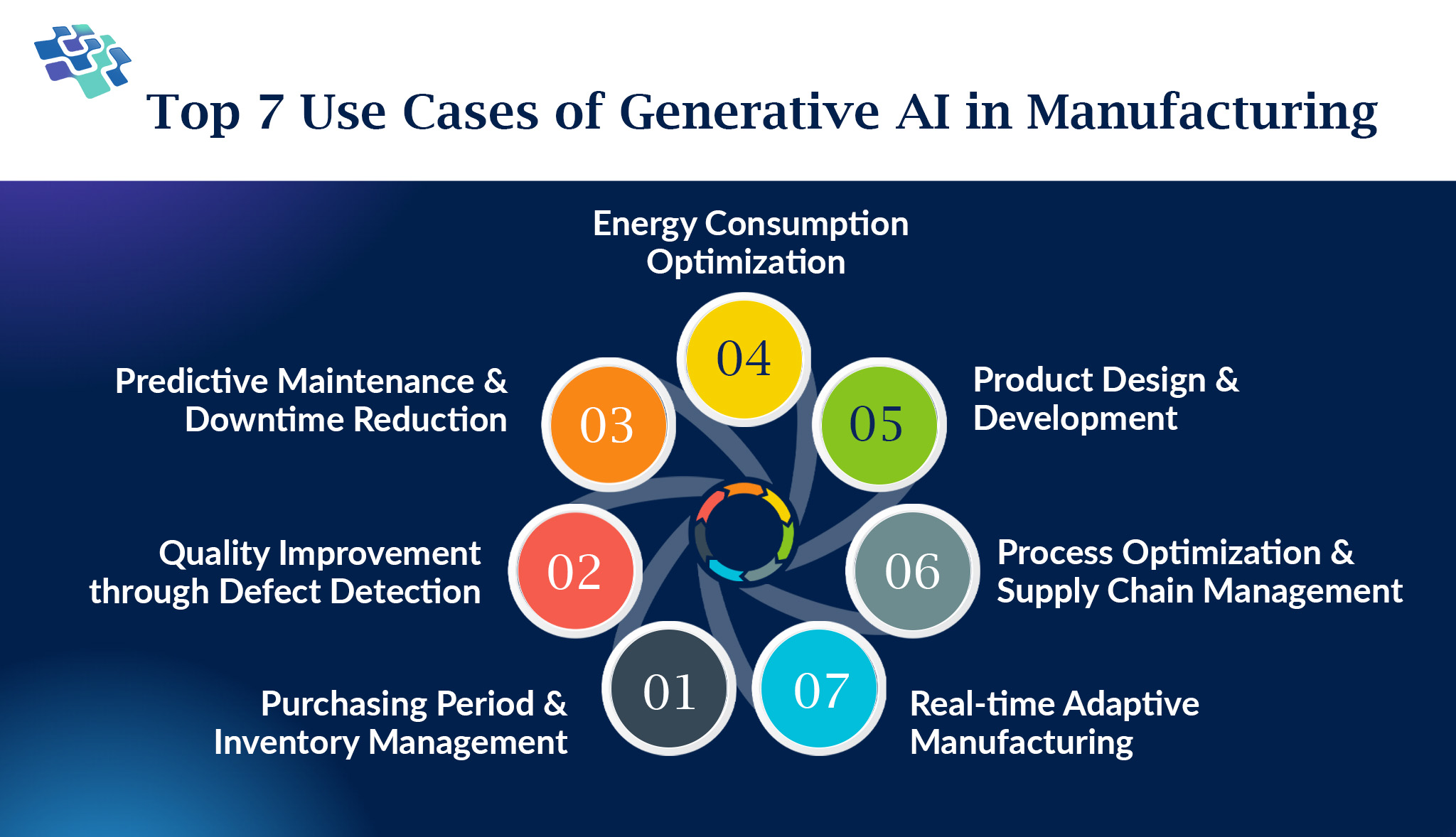

7 Most Important Use Cases of Generative AI in Manufacturing

Over the next ten years, businesses are expected to lose 45% of their average yearly profits. In addition, businesses are having trouble filling positions, with 54% of manufacturers reporting a labor shortage.

Stay In the Know

Get Latest updates and industry insights every month.

1. Predictive Maintenance & Asset Optimization

1. Predictive Maintenance & Asset Optimization