How AI in Manufacturing Industry is an Ultimate Game Changer?

We will discuss how is AI used in manufacturing and how cognitive machines anticipate issues before they arise and help humans accomplish tasks more quickly and efficiently. So, grab a seat and prepare to see how artificial intelligence isn’t simply revolutionizing the manufacturing industry—it’s becoming the change agent!

Facing High Operational Costs? Leverage Our AI Expertise to Optimize Efficiency and Reduce Expenses

“AI can fully automate complex tasks and provide consistent and precise optimum set points in autopilot mode. It requires less manpower to maintain, and—equally important—it can be adjusted quickly when management revises manufacturing strategy and production plans.”- Mckinsey

Role of AI in Manufacturing Industry

It is well-acknowledged that artificial intelligence is a fantastic tool for the global manufacturing industry. There are already instances where AI can aid the development of the modern manufacturing process in production. One notable illustration of this is quality control. AI is better than humans in identifying product-related flaws that are frequently overlooked since it can quickly evaluate copious amounts of data. Image recognition is a prime example of how AI helps with quality control. With careful analysis and a process that allows AI to visually evaluate every product on the production line, flaws will be found promptly. Because of this, there will be cost savings and improved quality.

AI algorithms allow for the simplification of predictive maintenance. Additionally, it enables them to become extremely effective and to be widely adopted. Analyzing data from machine sensors is one of the many distinctive AI applications in manufacturing. This is done to detect issues before they become expensive interruptions. This extremely proactive strategy also improves efficiency by reducing downtime, which permits higher total productivity.

Demand forecasting systems with AI help enable manufacturers to predict demand and change production levels accordingly more accurately. Any such system’s ability to optimize resource allocation, reduce waste, and carry out a highly efficient production process is just one of its numerous benefits.

Top 4 Benefits of AI in Manufacturing Industry

There are numerous benefits of integrating AI into manufacturing operations. In comparison to labor-intensive, multi-level manual tests, it improves overall product quality by playing a critical role in defect detection. AI integration has resulted in a noticeable decrease in operational time. Apart from this here are the top 4 benefits of AI in manufacturing sector.

- Enhanced Product Quality: AI-driven quality control solutions enable manufacturers to identify and address flaws that would otherwise go undetected when following standard operating procedures. Defect detection rates can be increased by up to 90% using AI technologies, according to McKinsey.

- Cost Reduction: Organizations can achieve improved equipment performance and significant cost savings on repairs and downtime by using predictive maintenance AI software solutions and smart resource allocation. Organizations that use AI in their business operations have seen a 10% drop in production expenses.

- Production Design: The idea of a “digital twin,” made possible by AI, has empowered the manufacturing industry. Information on raw materials, product weight, dimensions, manufacturing processes, cost, and resource limitations are fed into generative design software. The AI system then produces a range of design possibilities, giving producers a thorough grasp of their products.

- Energy Efficiency: In the modern manufacturing environment, energy efficiency is essential. Businesses can save a lot of money with AI-automated energy management. Artificial Intelligence evaluates energy consumption to maximize production unit expenses, freeing up funds for marketing or innovation.

Struggling with Supply Chain Management? Our AI Tools Enhance Visibility and Streamline Operations

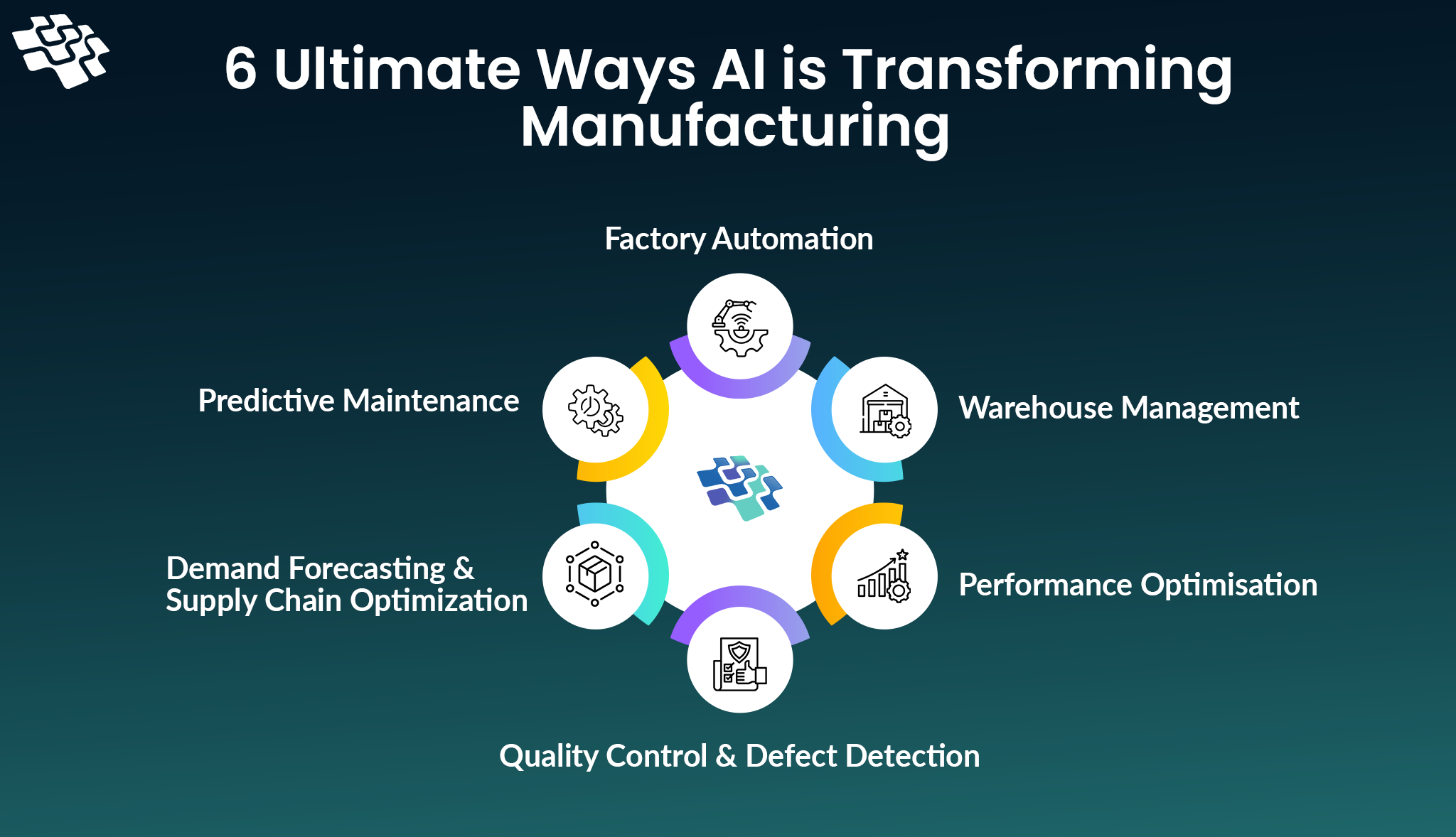

How AI in Manufacturing Industry is Transforming It: 6 Ultimate Ways

Artificial intelligence is driving a significant transformation in the manufacturing sector, leading to previously unheard-of breakthroughs and operational improvements. These are the top 6 AI use cases in manufacturing with related examples.

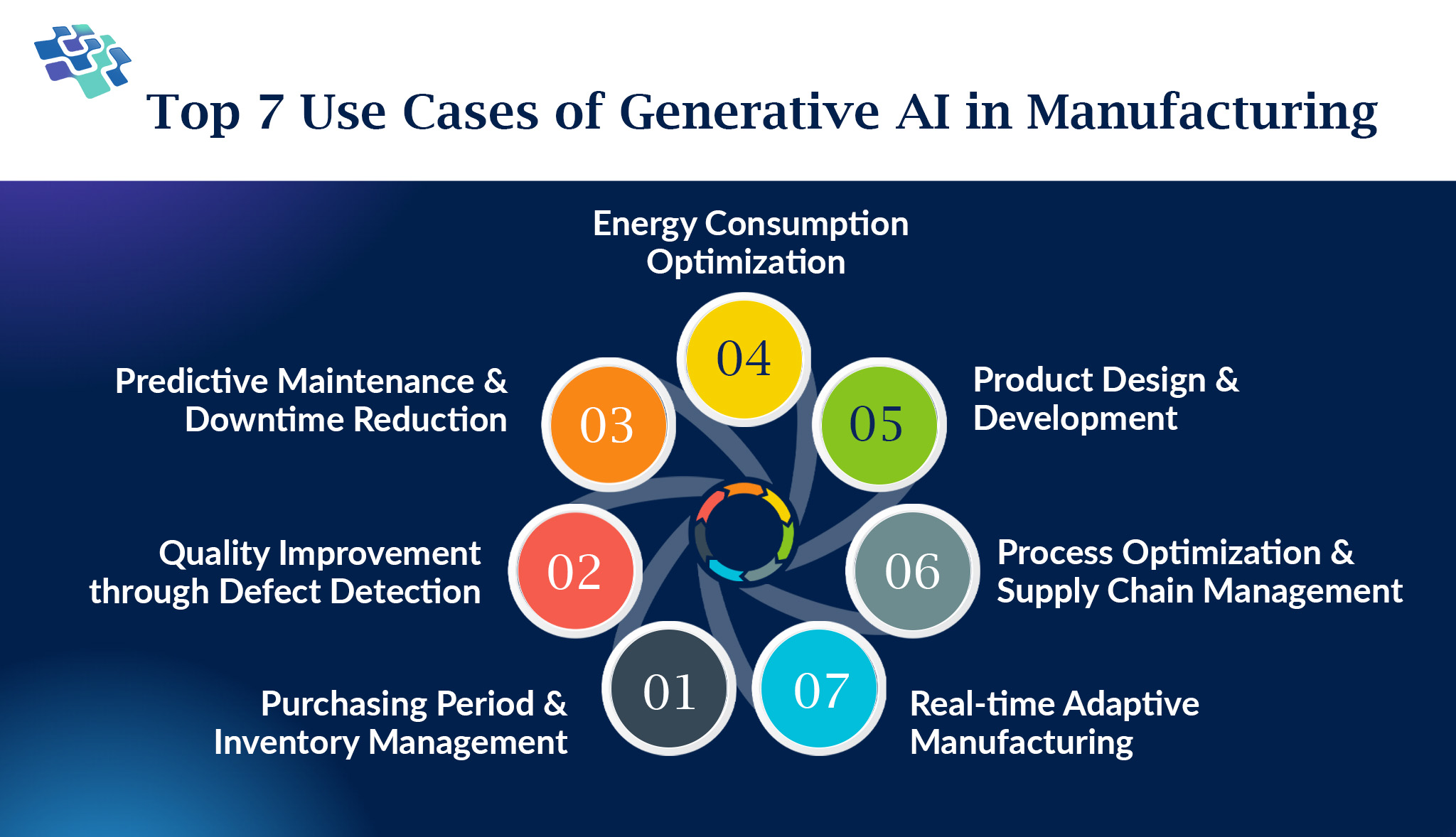

1. Predictive Maintenance

1. Predictive Maintenance

AI is driving an innovation that is drastically changing the manufacturing landscape: predictive maintenance. By using machine learning algorithms and advanced analytics, AI in manufacturing industry enables businesses to proactively monitor and anticipate equipment problems, reducing downtime and improving maintenance schedules. The digital twin is a key idea in predictive maintenance. Businesses are utilizing digital twins and advanced analytics to maximize maintenance schedules, predict equipment breakdowns, and increase operational efficiency and cost-effectiveness – all by leveraging the power of data.

Digital twin technology used by Ford is a noteworthy example of predictive maintenance AI software solutions in the manufacturing sector. Each car model that Ford makes has a unique digital twin, with each twin devoted to a particular stage of production from conception to completion. Energy loss is accurately identified by the digital twin for manufacturing facilities, highlighting areas that can be conserved and production lines optimized overall.

2. Factory Automation

With the introduction of AI, factory automation—a fundamental component of manufacturing—has experienced a significant transformation. An era of productivity, cost-effectiveness, and efficiency in manufacturing settings has been ushered in by the development of AI and ML. Automation powered by AI and equipped with ML and computer vision algorithms can handle complex jobs with accuracy and flexibility. These automated machines can do complex assembly tasks, evaluate quality control, and even work seamlessly in tandem with human workers.

Machine learning systems accurately predict equipment breakdowns by analyzing real-time data from sensors and equipment and recommending preventive maintenance techniques. Through proactive maintenance, equipment performance is maximized, downtime is reduced, and maintenance costs are reduced. Think of a heavy machinery manufacturer that uses AI to anticipate production line malfunctions and schedule maintenance accordingly. Significant cost reductions and less unscheduled downtime are the outcomes of this.

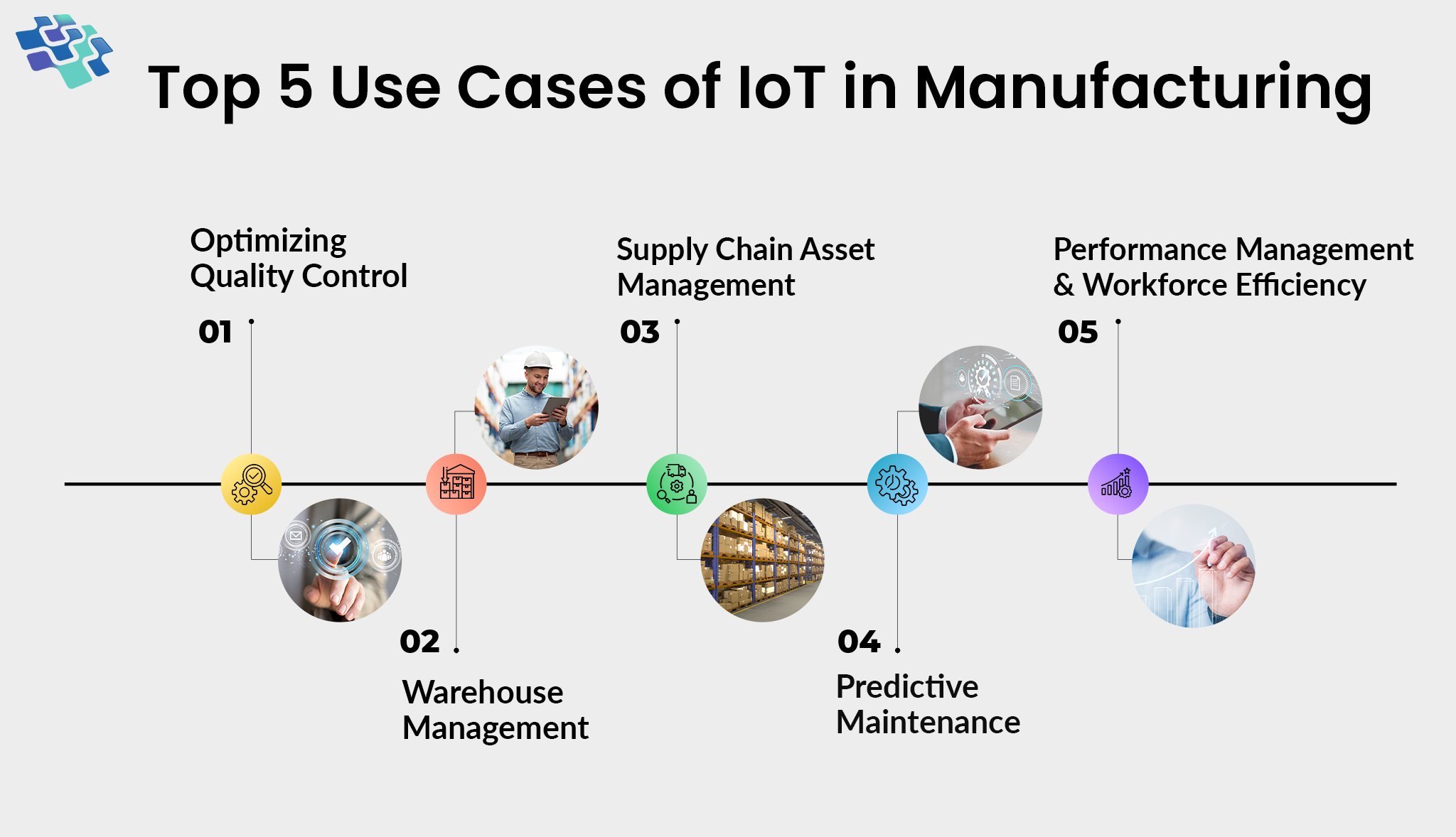

3. Warehouse Management

AI is also transforming the manufacturing industry’s warehouse management sector, improving accuracy, efficiency, and cost savings. To precisely forecast demand patterns, AI systems can assess previous sales data, current stock levels, and market trends. AI-driven solutions can help improve warehouse order fulfillment procedures through resource allocation, picking route optimization, and order analysis of incoming orders.

As a result, orders are processed more quickly, there are fewer errors, and customers are happier. To optimize intralogistics processes and improve inventory management and visibility, BMW, for example, uses AI-driven autonomous guided vehicles (AGVs) in its manufacturing warehouses.

4. Performance Optimization

Manufacturing relies heavily on performance optimization, and AI is revolutionizing this field. One area where AI shines is predictive analytics, where it can analyze past data, current sensor data, and other pertinent variables to find trends, spot abnormalities, and generate data-driven forecasts.

Businesses can manage their production schedules by employing AI manufacturing solutions, which analyze a range of parameters including supply chain dynamics, machine performance data, and demand projections. This leads to better use of available resources, shorter lead times, and higher levels of customer satisfaction. By analyzing energy usage patterns and suggesting energy-saving methods, artificial intelligence systems in manufacturing can also optimize energy consumption, minimize waste, and boost sustainability efforts.

5. Quality Control & Defect Detection

Manufacturers place the utmost importance on ensuring the finest quality products. Significant advancements in defect detection and quality control have been made possible by AI. AI-powered vision systems can analyze things faster and more precisely than ever before. These systems can spot even the smallest flaws, irregularities, or departures from the norm, which improves product quality and lowers waste.

To maintain ideal quality levels, AI can also be used to continuously monitor, assess, and make necessary adjustments to manufacturing processes.

6. Demand Forecasting & Supply Chain Optimization

For manufacturers to manage inventory, arrange production schedules, and satisfy customer expectations, accurate demand forecasting is essential. To accurately forecast future demand, artificial intelligence, especially machine learning algorithms, can examine past sales data, industry trends, and outside variables. This enables manufacturers to save carrying costs and boost customer satisfaction by streamlining production schedules, minimizing stockouts, and minimizing overstocking.

With AI technologies, businesses can do thorough analyses of supply chain data and gain insights that can optimize distribution, inventory control, and logistics. In the end, machine learning algorithms can lead to lower prices, quicker delivery times, and improved performance by predicting demand patterns, optimizing inventory levels, and recommending the most effective shipping routes.

Refer to Our Podcast for Further Details:

Weathering the Storm- Why Supply Chain Resilience is Always in Season

Dealing with Production Bottlenecks? Our AI Solutions Optimize Workflow and Boost Productivity

Future of AI in Manufacturing Industry

The use of AI in manufacturing is becoming increasingly important as the globe struggles to meet its sustainability goals. Manufacturers may drastically lessen waste, streamline their operations, and enhance their environmental impact by utilizing AI technology. Artificial intelligence has a promise to foster progress in sustainable manufacturing. Large volumes of data from many sources can be analyzed by AI algorithms, which can then spot patterns and trends that people might miss. These realizations can help streamline production procedures, boost productivity, and cut waste.

AI can be used, for example, to monitor manufacturing processes in real time and identify abnormalities and faults before they result in serious waste or quality problems. This proactive approach improves the quality of products while positively impacting sustainability. For additional information, see our post on using AI in manufacturing for real-time monitoring. AI can also help with demand forecasting, which helps producers better anticipate their production demands and allocate resources efficiently. By doing this, excess production and its related waste can be decreased.

How NextGen Invent’s Custom AI Solutions Can Help Businesses Achieve Manufacturing Excellence?

As this blog has covered, there are a plethora of artificial intelligence applications in manufacturing that demonstrate the crucial role AI in manufacturing industry is playing in transforming different parts of it. It has increased productivity, accuracy, and cost-effectiveness in various areas, including supply chain management and predictive maintenance.

Businesses will need expert artificial intelligence development services to fully appreciate the influence of AI in manufacturing. Because of its proficiency in creating innovative AI and ML solutions, especially for manufacturing businesses, NextGen Invent has established itself as a pioneer in the sector. As a frontrunner in advancing technical innovation, NextGen Invent has a strong portfolio that includes the development of 100+ software products, the execution of more than 550 projects, and the production of 500+ AI models.

NextGen Invent is pushing innovation and developing unique AI/ML solutions that are redefining industry norms as the manufacturing landscape changes. Manufacturing companies may fully realize the benefits of AI and ML, revolutionize their processes, and prosper in today’s fast-paced and cutthroat market by working with our team of expert AI data scientists.

Frequently Asked Questions About AI in Manufacturing Industry

Related Blogs

How IoT in Manufacturing is Revolutionizing the Industry

The way industries use data, interact, and function has changed as a result of IoT. In fact, according to a survey of executives in the manufacturing industry, 86% of them thought that smart factory projects would propel the industry during the next five years.

Everything Businesses Need to Know About Warehouse Management Systems

Warehouse and distribution tasks need to be optimized, monitored, and managed by any large, complex logistics or supply chain company. These responsibilities include inventory management, order processing, and dock scheduling.

Use Cases of Generative AI in Manufacturing

Consider a scenario in which data is more than just numbers and figures. Rather, it is a dynamic force that molds the fundamental essence of business activities. That is the exact contribution that generative AI in manufacturing makes.

Stay In the Know

Get Latest updates and industry insights every month.

1. Predictive Maintenance

1. Predictive Maintenance