7 Most Important Use Cases of Generative AI in Manufacturing

The fact that the global market for gen AI in the manufacturing industry is projected to be valued at approximately USD 6.3 million by 2032 is not at all surprising. The advantages of generative AI for manufacturing businesses, like improved product design, lower expenses, higher worker productivity, and more, facilitate this expansion.

Minimize Defects & Enhance Product Quality with Our Gen AI Software Solutions

“79% of global executives said they had some familiarity with Generative AI, and 22% said they use it regularly in their work. On the manufacturing front, Gen AI can unlock untapped productivity during production, leveraging root cause analysis to predict failures and reduce defects, and draft easy-to-follow dynamic work instructions. It can also augment operator stations by offering live, AI-supported troubleshooting and operating guidelines.”– Mckinsey

What is Generative AI in Manufacturing: Overview

A new era of automation and connectivity has been ushered in by Industry 4.0, which is defined by the integration of the Internet of Things and cyber-physical systems into the production process. Gen-AI is essential to advancing Industry 4.0’s transformative potential. There are many generative AI use cases in many different fields, such as image synthesis, drug discovery, and natural language processing. It serves as the foundational technology for chatbots that produce languages that resemble that of a human being, such as OpenAI’s ChatGPT and GPT-4.

Manufacturers can push the limits of operational excellence through generative AI models and algorithms.

- It makes automated design optimization possible, which enables the quick investigation of numerous design iterations and combinations. This improves the functionality and performance of the product while also quickening the product development process.

- With the help of automated design optimization, material property modeling, synthetic data generation, and simplified manufacturing systems, Gen AI in manufacturing enables businesses to transform their operations and output, putting them in a competitive position for success in the market today.

Gen-AI has emerged as a force for change in the manufacturing sector as businesses aim for excellence.

Benefits of Incorporating Generative AI in Manufacturing Industry

Generative AI in the manufacturing industry can now operate more efficiently and have fully automated facilities. Improved integration might enable it to pinpoint inefficiencies and provide insightful information about every facet, including production, the supply chain, and customer relations. Here, we’ll go into further detail about the main advantages of generative AI in manufacturing.

- Data-Driven Decision Making: Smarter, data-driven decision-making is one of generative AI’s main advantages in production. Gen AI and data analytics together provide advantages over traditional data analytics, enabling the management hierarchy to find intricate correlations and hidden patterns in the dataset. Making strategic decisions in various manufacturing domains, including supply chain management, inventory control, quality assurance, production planning, and scheduling, is facilitated by precise real-time insights.

- Improved Product Quality: Manufacturers can assess and identify flaws in real time by using generative AI, which can be trained on massive volumes of visual inspection and product quality data. This feature ensures a quick turnaround in the rectification procedure, which minimizes waste. AI can also reduce variability and improve product consistency by using simulations to optimize manufacturing parameters and determine the best settings for high-quality output.

- Enhanced Productivity & Efficiency: Automation of repetitive tasks, including inventory management, supply chain operations, order processing, quality inspection, and human-like discussions with clients/customers, is made possible by the application of Gen AI in manufacturing processes. Productivity is known to increase when tasks enabled by generative AI automation are finished quickly, more consistently, and error-free.

Reduce Downtime & Embrace Our Predictive Maintenance Solutions Powered by Generative AI

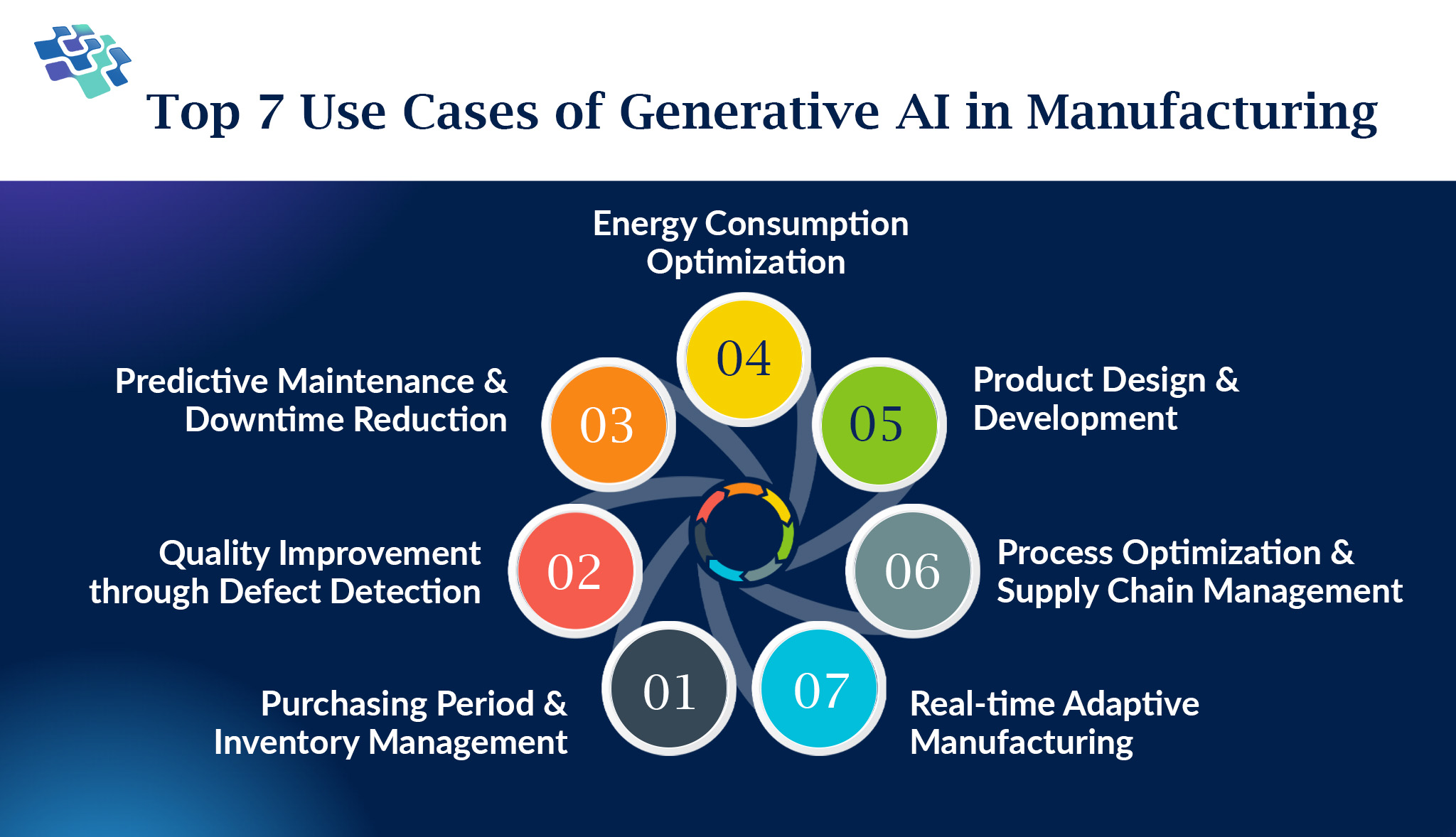

7 Most Crucial Generative AI Use Cases in Manufacturing Industry

Among the industries that benefit from the use of generative AI is manufacturing. Generative AI has numerous applications in manufacturing, including product design and inventory management. Here are some manufacturing-related generative AI use cases:

1. Purchasing Period & Inventory Management

1. Purchasing Period & Inventory Management

Manufacturing faces significant challenges with inventory management, particularly in times of unstable economic and geopolitical environment and rising customer demand. Optimizing inventory levels is a high objective for 68% of supply chain leaders for the next three years, according to a recent survey. Generative AI is already being used by consumer goods companies like Nike to forecast demand for their goods with accuracy. Generative AI gathers information from various data sources, including past sales, industry trends, customer behavior, and seasonal patterns. To produce the best inventory suggestions, the system will also take inventory thresholds and warehouse storage capacity into consideration.

Purchasing period management is a further use of generative AI in inventory management. Generative AI tells manufacturers when it makes the most financial sense to purchase massive amounts of raw materials by analyzing current and projected future pricing.

2. Quality Improvement through Defect Detection

Generative AI leverages machine learning algorithms to analyze sensor data from manufacturing processes. By detecting subtle patterns that indicate potential product flaws, it can identify defects early in the production cycle. This proactive approach enables manufacturers to address issues before products are shipped, significantly reducing the risk of costly recalls. Through continuous monitoring and analysis, generative AI ensures that only high-quality goods reach customers, thereby enhancing overall customer satisfaction.

The technology not only improves product quality but also optimizes operational efficiency, leading to a more reliable and streamlined manufacturing process. By integrating AI-driven defect detection, businesses can maintain a competitive edge in the market while delivering superior products to their consumers.

3. Predictive Maintenance & Downtime Reduction

Generative AI employs advanced machine learning techniques to analyze sensor data from industrial machinery, identifying patterns that predict potential malfunctions. By forecasting these issues, manufacturers can schedule maintenance proactively, preventing unexpected breakdowns. This predictive maintenance strategy minimizes unplanned downtime and ensures continuous, efficient operation of equipment. The AI-driven insights enable more accurate maintenance schedules, optimizing resource allocation and reducing maintenance costs. As a result, equipment performance is enhanced, leading to improved operational efficiency and extended machinery lifespan.

With generative AI for predictive maintenance, manufacturers can achieve higher reliability and productivity, maintaining a competitive edge in their industry while ensuring the consistent delivery of high-quality products.

4. Energy Consumption Optimization

Generative AI analyzes process and machine activity data to optimize energy usage in manufacturing. By identifying patterns and inefficiencies, it helps manufacturers pinpoint opportunities for energy savings while maintaining production levels. This optimization not only reduces operational costs but also supports sustainable practices by lowering energy consumption and carbon footprint. The AI-driven approach allows for real-time adjustments and long-term planning, ensuring that energy use is efficient and aligned with environmental goals.

Integrating generative AI into manufacturing processes promotes a balance between high industrial output and sustainable operations, benefiting both the environment and the bottom line.

5. Product Design & Development

The technology-driven methodology of generative AI opens design possibilities that are well beyond the capacity of human cognition. It presents a wide range of design options, including unusual structures and designs. As a result, product innovation undergoes a revolutionary change that produces goods that are effective, economical, and distinctive by nature, putting companies at the forefront of their corresponding sectors. In the first stage, engineers specify the characteristics, restrictions, and goals of the design. These may include goals about the cost of materials, production processes, standards of performance, and working conditions. After receiving this input, the generative AI system creates several design options that meet these requirements.

After these designs are made, machine learning techniques are used to assess and improve them. With every iteration, the system learns and gets better, intelligently adjusting the designs to achieve the desired results more precisely and effectively.

The following are the outcomes:

- Enhanced efficiency in design,

- Savings on costs, and

- Increased originality.

6. Process Optimization & Supply Chain Management

Generative AI optimizes resource allocation, production layouts, and tool paths to become the architect of excellence in manufacturing. AI systems painstakingly create a manufacturing ecosystem that is fully connected, increasing productivity, and saving money. Because of their operational agility, manufacturers can quickly adjust to the dynamically shifting needs of the automobile sector.

Gen AI excels in the strategic benefit of demand prediction and inventory optimization in the automation industry. Equipped with machine learning and data analysis, artificial intelligence algorithms precisely forecast demand trends. As a result, a just-in-time production model is ensured by an efficient inventory management system, which also reduces excess inventory costs and strengthens the overall robustness of the supply chain.

7. Real-time Adaptive Manufacturing

Real-time adaptive manufacturing—in which production processes dynamically adapt in response to data insights—is made possible by generative AI. This feature enables producers to react quickly to shifts in consumer demand, interruptions in the supply chain, or unexpected changes in the market. Production thus becomes more responsive to the automotive industry’s volatility and more efficient.

One example of real-time adaptability is Toyota’s use of generative AI in its production systems. Toyota demonstrated the revolutionary effect of generative AI on manufacturing excellence by bringing AI-driven analytics into its manufacturing processes. This allowed Toyota to increase production efficiency, decrease waste, and improve the flexibility of its production lines to quickly adapt to changes in market demands.

Prevent Equipment Failures & Ensure Reliability with Our Gen AI Predictive Maintenance

Future of Generative AI in the Manufacturing Industry

Without question, Gen AI has the potential to completely change the manufacturing sector in the future. It has the potential to transform industries and spur innovation due to its capacity to evaluate large volumes of data and produce insightful results. Given the circumstances, the future of Gen AI’s impact and application in manufacturing appears to be very bright, with a wide range of advantages and applications being investigated.

However, the use of generative AI in industrial comes with challenges and risks, just like any other modern technology. Artificial intelligence presents significant challenges to individuals and businesses, ranging from the possibility of biased or erroneous outcomes if algorithms and machine learning models are not adequately trained or verified, to the potential for automation to replace human labor. It’s crucial to remember that there are ways to lessen the likelihood of these issues.

Gen AI holds great promise to transform the manufacturing sector through its capacity to generate instant insights, improve operations, and stimulate innovation. Manufacturing businesses can obtain a competitive edge in their respective industries by adopting this technology and managing the risks involved.

How Does NextGen Invent Help Businesses Tap into the Potential of Generative AI in Manufacturing?

At NextGen Invent, our profound knowledge of manufacturing processes, along with our proficiency in Generative AI-driven robust technologies, make us the ideal custom generative AI development services provider. Our Gen AI solutions are intended to:

- Transform Product Design: Harness the power of generative AI to revolutionize your product design process. We create cost-effective, efficient, and innovative solutions that give you a competitive edge in the market, setting new standards in creativity and functionality.

- Enhance Quality Control: Our AI-driven systems ensure superior product quality by significantly reducing defects and minimizing recalls. This not only saves time and resources but also enhances customer satisfaction with consistently high-quality products.

- Optimize Predictive Maintenance: Eliminate unexpected downtimes with NextGen Invent’s predictive maintenance solutions powered by generative AI. Our technology ensures smooth, uninterrupted operations, enhancing equipment reliability, and operational efficiency.

Staying ahead in the competitive domain is crucial, and leveraging the right generative AI development services is key to achieving this. Contact our AI data scientists to explore the boundless possibilities that generative AI offers and transform your operations today.

Frequently Asked Questions About Generative AI in Manufacturing

Related Blogs

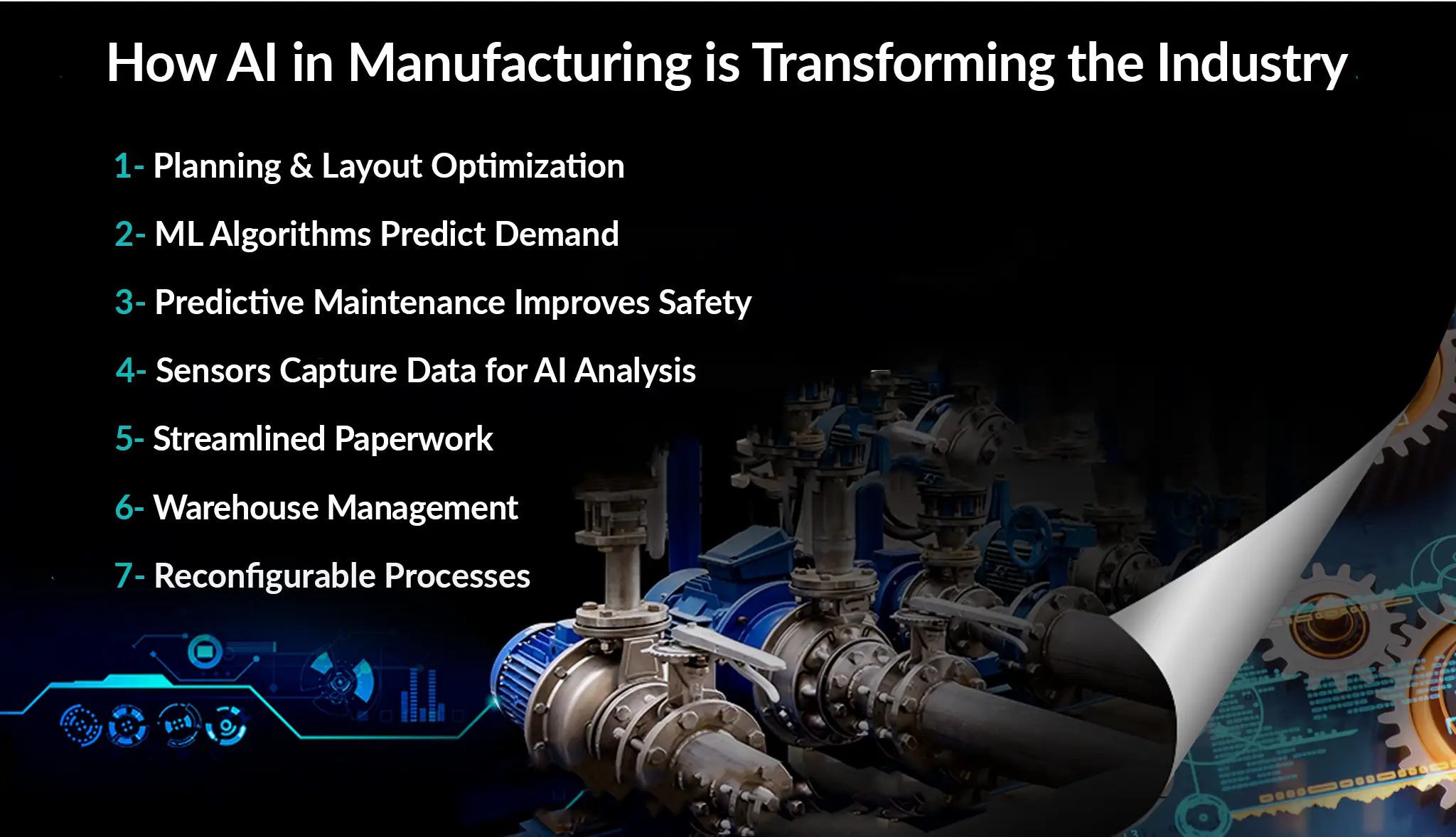

How AI in Manufacturing is Transforming the Industry?

A fiercely global economy can be kept competitive with the advent of AI in manufacturing. The integration of artificial intelligence in manufacturing brings transformative potential, employing algorithms to process data from sensors and human inputs.

Industry-Specific Generative AI Use Cases in 2024

Generative AI use cases exemplify the multifaceted applications of AI in mimicking human-like content generation. Utilizing vast datasets, algorithms like ChatGPT and DALL·E 2 discern patterns and structures, replicating similar parameters in generated content.

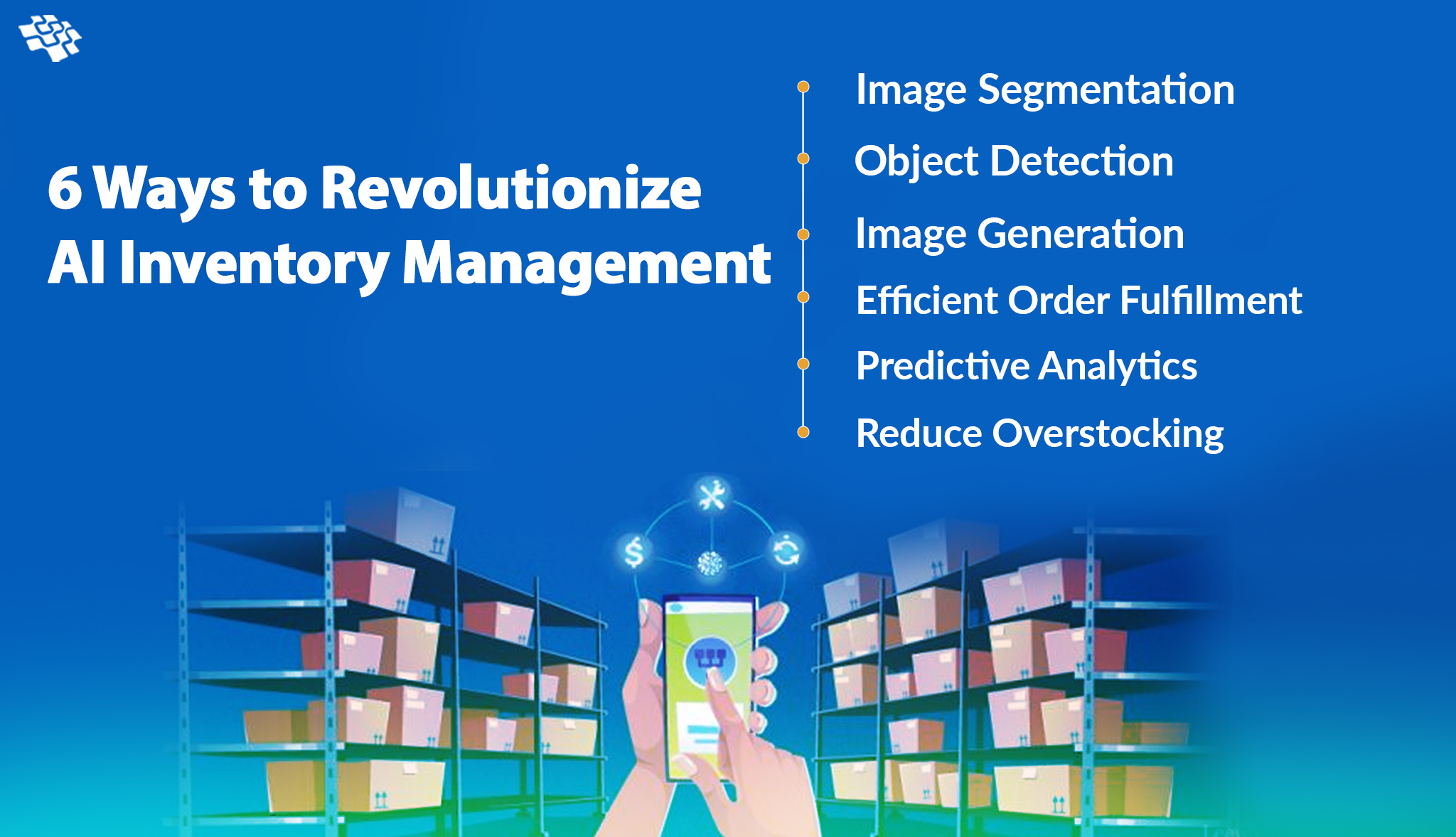

How CV is Revolutionizing AI Inventory Management?

AI inventory management is revolutionizing large-scale corporate operations by enhancing efficiency and accuracy. Through precise product location tracking, this innovative technology optimizes processing and stocking, ensuring seamless movements with the right force.

Stay In the Know

Get Latest updates and industry insights every month.

1. Purchasing Period & Inventory Management

1. Purchasing Period & Inventory Management