How is IoT Reshaping Industrial Automation?

Despite the growth of IoT devices and users in industrial automation, organizations must tackle persistent concerns regarding security and interoperability. Currently, around 70% of businesses have embraced digital transformation strategies, reinforcing their significance in the IT realm.

“By 2025, there will be 55.7 billion IoT devices, generating about 80 ZB of data. Businesses will increasingly integrate their internal processes on digital platforms. Industries will also prioritize expanding their ecosystems to meet market demands and enhance adaptability.”- IDC

How Does IoT Operate?

By enabling seamless communication and automation between objects without the need for human interaction, the Internet of Things (IoT) revolutionizes how data is transported and processed. IoT devices serve as the backbone of this interconnected network, seamlessly collecting and transmitting data from various sources to enable appropriate responses from the connected objects. These devices are powered by embedded systems consisting of processors and microchips, which efficiently gather data from the device’s domain. Alongside IoT devices, a comprehensive ecosystem of web-enabled smart gadgets, network protocols, and applications collaborates harmoniously to establish a network that simplifies data transmission and reception. This system’s operation revolves around four key components, enabling a seamless and independent flow of data: Sensors, Connectivity, Data Processing, End-Users.

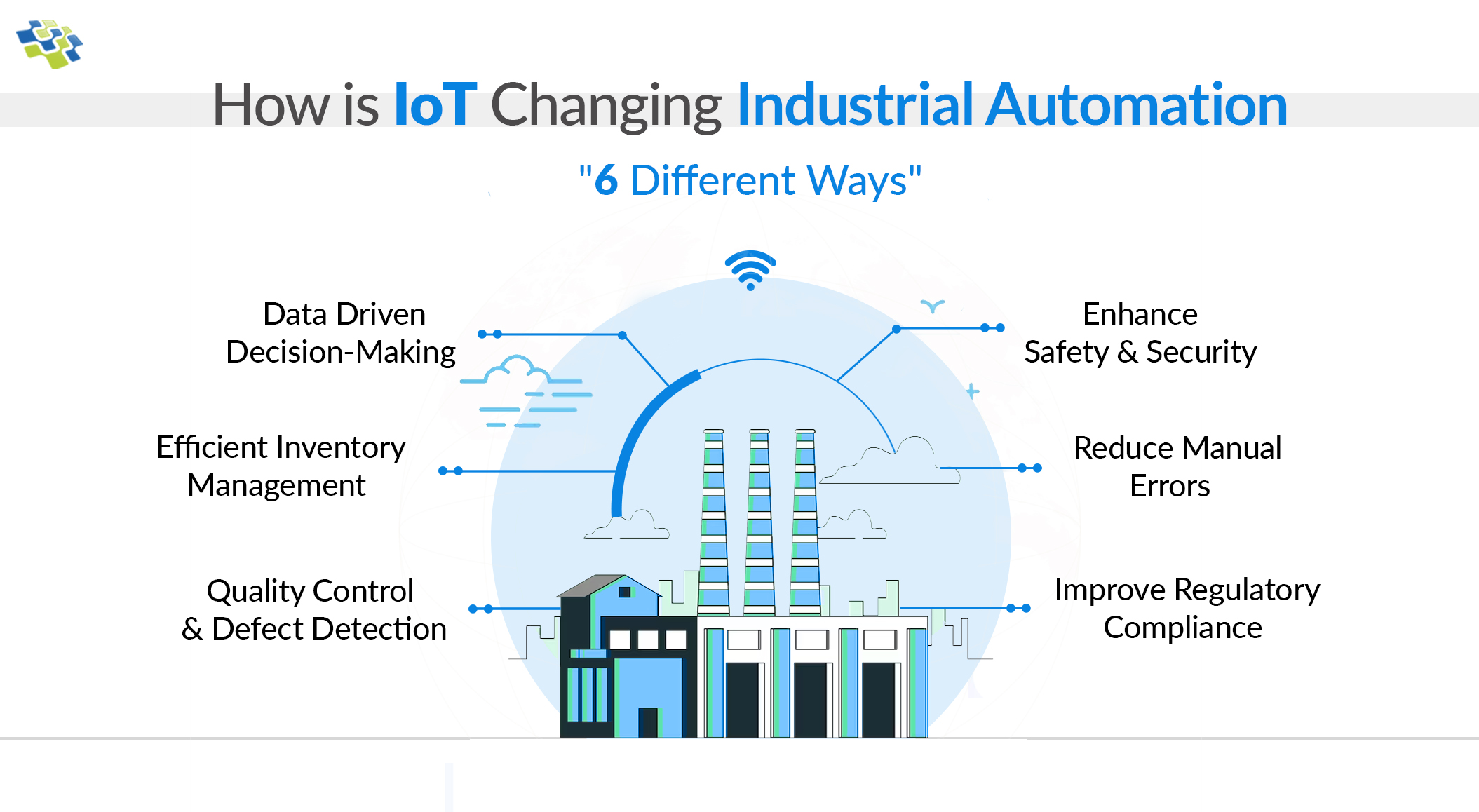

6 Ways How IoT is Changing Industrial Automation

The Internet of Things has become instrumental in driving significant transformations across various industries, particularly in the realm of industrial automation. IoT is changing industrial automation by:

1. Quality Control & Defect Detection

1. Quality Control & Defect Detection

Industrial automation has undergone a revolution because of the use of IoT sensors and data analytics in quality control processes. Rapid detection of deviations and abnormalities is made possible by ongoing monitoring of production factors and product quality. By enabling prompt corrective action and minimizing waste, this timely detection increases production. Businesses can increase quality standards, process effectiveness, and customer satisfaction by utilizing real-time insights. IoT-driven quality control drives significant advancements in industrial manufacturing.

2. Efficient Inventory Management

Real-time tracking of inventory levels made possible by IoT revolutionizes inventory management. Organizations can keep an eye on stock levels, track product movement, and automate the restocking process with the use of sensors and RFID tags. This continuous connectivity makes it possible to manage the supply chain effectively, reducing stock outs and surplus inventory. Businesses can cut expenses and increase operational efficiency by reducing the cost of holding inventory and streamlining the procurement process. The performance of the supply chain is improved through IoT-driven inventory management.

3. Data Driven Decision-Making

IoT devices and sensors enable the collection of extensive data from machines and processes, empowering businesses to gain valuable insights and make informed decisions. Real-time access to production data enhances decision-making by providing producers with immediate visibility into operations. Through tracking and analysis of equipment and device data, organizations can swiftly identify and address issues, reducing waste and enhancing productivity. Integration of IoT data with advanced analytics techniques like machine learning and AI uncovers patterns and insights that are challenging to discover manually. Consequently, companies can anticipate demand, optimize production schedules, and unlock new growth opportunities with greater efficiency and accuracy.

4. Enhance Safety & Security

IoT-driven industrial automation has significantly enhanced industry security and safety through real-time equipment and procedure control and monitoring. By continuously collecting and analyzing device data, businesses can proactively identify and mitigate potential safety hazards before they escalate. IoT sensors play a crucial role in tracking environmental variables such as temperature, humidity, and gas concentrations, promptly alerting operators to any hazardous changes. This proactive approach prevents accidents and ensures the well-being of the workforce. With the ability to detect and respond to safety risks in real-time, IoT empowers organizations to maintain a safe working environment, safeguarding both employees and assets.

5. Reduce Manual Errors

Human errors, regardless of their magnitude, can disrupt operations and impact accuracy. IoT devices offer a crucial advantage in terms of reliability and functionality. By automating processes, IoT reduces the workload on industries, allowing them to focus on more critical tasks rather than dedicating excessive attention to manual operations. With IoT’s dependable performance, organizations can mitigate the risks associated with human error and ensure consistent and accurate execution of tasks. This streamlining of operations not only enhances efficiency but also frees up resources for businesses to allocate toward strategic initiatives and innovation.

6. Improve Regulatory Compliance

Automation provides significant support to businesses operating under strict quality regulations imposed by governmental bodies. By minimizing productivity flaws, automation enables companies to adhere to stringent standards. For instance, in the food industry, regulations like the FDA Food Safety Modernization Act necessitate compliance with measures such as Current Good Manufacturing Practices (CGMP), Hazard Analysis and Critical Control Points (HACCP), and the FDA Retail Food Code. Automation empowers businesses to meet these requirements by ensuring consistent and controlled manufacturing processes. By upholding quality standards, automation helps authorities protect consumers, enhance public health, and drive regulatory compliance across industries.

Further Read: Automatic Labelling- A Big Leap in Data Preparation for AI/ML Models

IoT Use Cases in Manufacturing

The adoption of IoT in manufacturing is primarily driven by several key factors that bring significant use cases to the industry:

1. Predictive Maintenance

Predictive maintenance is a critical aspect of maintaining a functioning shop floor. By analyzing performance indicators and deploying sensors for real-time predictions, manufacturers can prevent equipment failures and downtime. Quick alerts and data insights help avoid crises, protecting both equipment and the workforce. This leads to lower supply chain costs, increased operational efficiency, reduced service calls, and significant time savings, particularly with 45% of assets deployed in the field.

2. Analytics-Based Scheduling Optimization

Leveraging IoT data and advanced analytics, manufacturing adopts analytics-based scheduling optimization to enhance production schedules. By analyzing historical and real-time data while considering resource limitations, manufacturers optimize resource utilization, resulting in reduced bottlenecks and increased throughput. This approach boosts operational efficiency, leading to a significant improvement in productivity, on-time delivery by 31%, and an impressive 20% increase in responsiveness to interruptions.

3. Risk Modelling

In manufacturing, IoT-driven risk modeling combines real-time data, historical records, and external factors to proactively identify potential risks. With a 75% accuracy in forecasting their impact, manufacturers implement preventive measures to mitigate disruptions. This approach ensures 95% operational continuity and maintains smooth operations. By leveraging IoT automation, manufacturers bolster their ability to navigate challenges and safeguard their processes against unforeseen events, ultimately boosting productivity and profitability.

4. Project Efficiency Analysis

Project Efficiency Analysis powered by IoT data is invaluable for the manufacturing industry. Real-time data and production indicators enable manufacturers to pinpoint inefficiencies and streamline workflows, leading to a remarkable 28% reduction in project timelines. By optimizing resource utilization, costs are cut by 25%, and productivity surges by 23%. Ultimately, this data-driven approach ensures manufacturing projects achieve higher success rates, delivering greater profitability and competitive advantage.

Further Read: The Power of Data- Manufacturing Organizations turning into Smart Factories

Conclusion

IoT has a significant and broad impact on industrial automation. The seamless integration of machines, sensors, and data analytics has enhanced the effectiveness, intelligence, and responsiveness of conventional production processes. IoT has paved the way for a new era of industrial automation, including real-time monitoring and optimization in addition to predictive maintenance. As industries continue to implement IoT technologies, they should see improved output, lower costs, and better overall performance.

Looking to leverage the power of IoT for your automation needs, look no further than NextGen Invent. As a leading IoT app development company specializing in IoT solutions, we have the expertise and experience to bring your automation vision to life.

Contact us today and let our team be your trusted partner in revolutionizing your industrial automation processes.

Stay In the Know

Get Latest updates and industry insights every month.

1. Quality Control & Defect Detection

1. Quality Control & Defect Detection