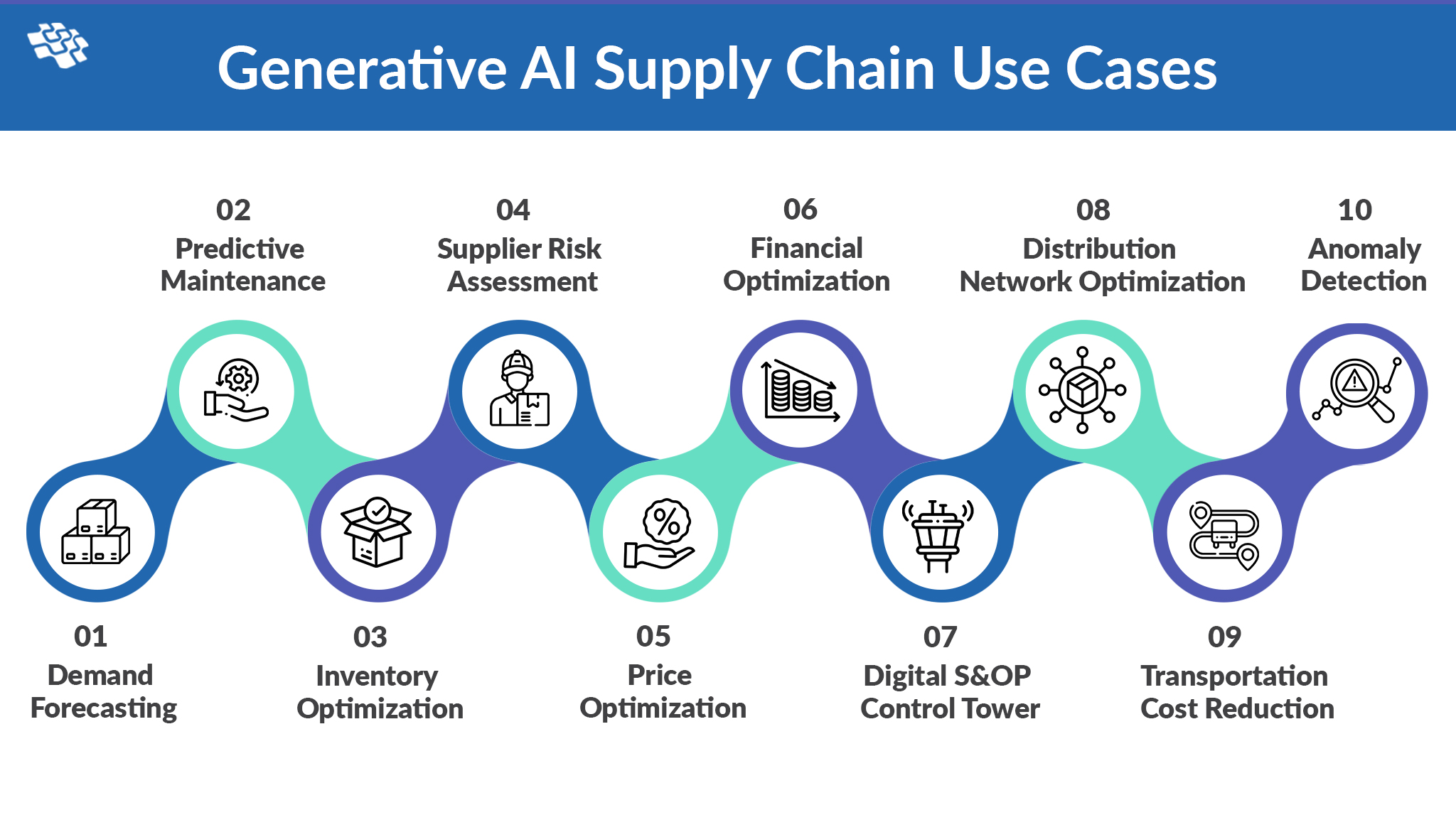

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then instantly evaluate the information to deliver insights.