How Do Businesses Optimize Supply Chain with Data Analytics?

Supply chain analytics emerges as the linchpin in contemporary supply chain networks, facilitating the transition to automated workflows for enhanced efficiency and competitiveness.

Transform Your Supply Chain: Achieve Data Accuracy, Break Silos, and Process Real-time Insights in Your Supply Chain Now!

“The explosive impact of data analytics on globalized companies has brought new opportunities for implementing data-driven decisions sweeping many industries and business functions. Data analytics is frequently used in the logistics/supply chain management industry to improve the system’s performance. As the supply chain performance depends on information to a high degree, big data analytics seems to be extremely useful in improving supply chain performance.”- Research Gate

Overview of Supply Chain Analytics

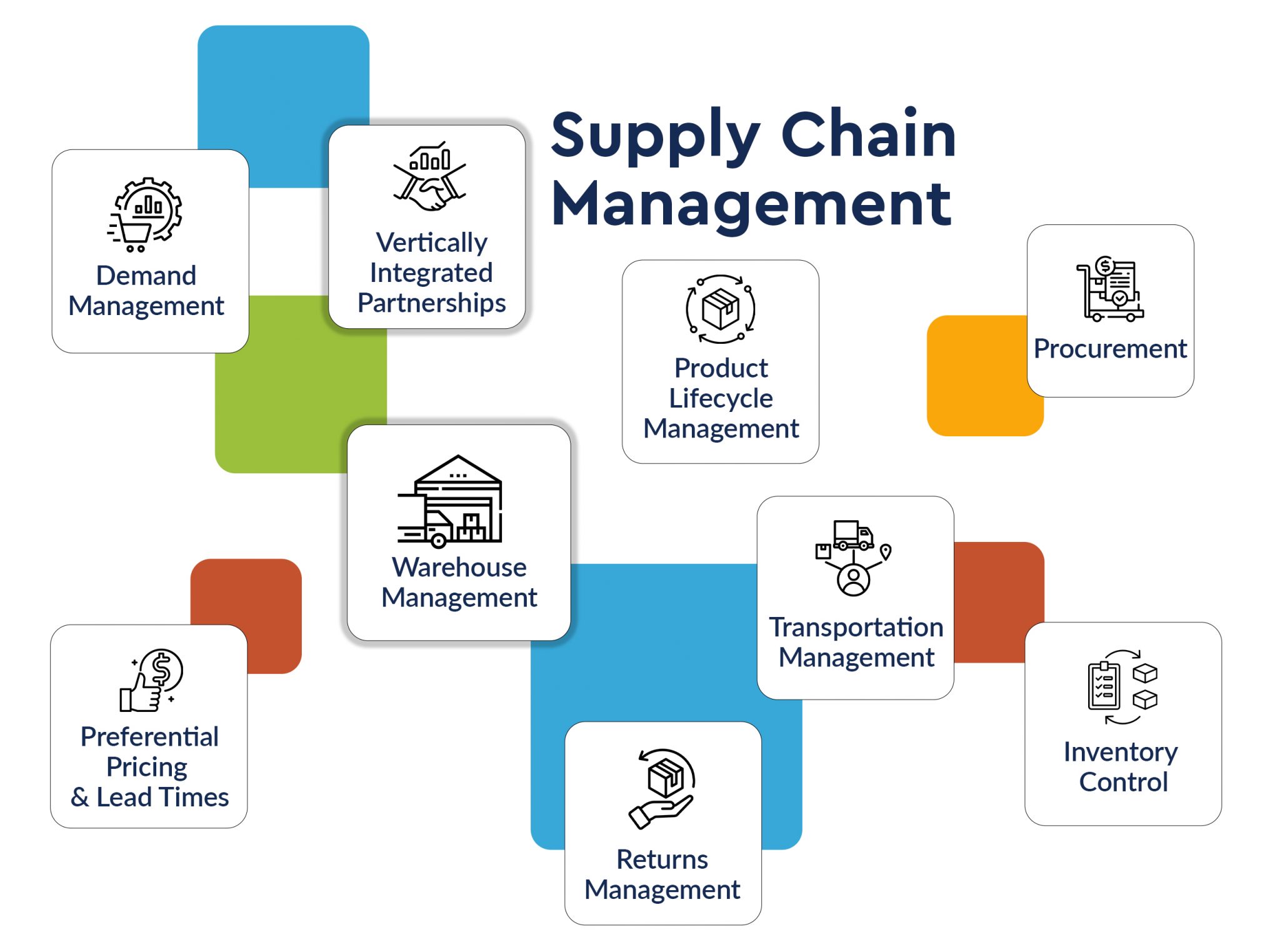

Supply chain analytics involves the comprehensive process of collecting, analyzing, and extrapolating data about all facets of supply chain operations, spanning from sourcing raw materials to delivering finished products to customers. As businesses recognize the immense value of data-driven insights, the adoption of supply chain analytics continues to surge.

By harnessing the power of analytics, organizations aim to optimize productivity, minimize costs, and enhance customer satisfaction. This strategic utilization of data enables businesses to make informed decisions, streamline operations, and adapt swiftly to market dynamics, fostering competitive advantage.

Challenges in Supply Chain Data Analytics

A complex software infrastructure is needed to execute some of the analytics applications that businesses may choose to use. Additionally, as they handle a growing amount of digital data, they have a greater need to ensure its security. So, let’s examine the potential challenges that supply chain data analytics may present in more detail.

- Data Silos: A significant challenge that businesses can have when attempting to use supply chain analytics software is the existence of multiple data silos. Data in logistics and supply chain is frequently dispersed over numerous different systems, including third-party solutions, business programs, and CRM platforms. It might be challenging for computers to recognize patterns that appear across data silos when there are so many sources. Therefore, to benefit from analytical solutions, it is essential to first combine data from all pertinent apps.

- Data Volume: The volume of data produced by businesses is expanding exponentially. The amount of digital information generated every day is increasing, and to make use of it, businesses must first efficiently manage and store it all. Many choose to create data lakes or data warehouses in this way to ensure that everything is kept safe and quickly accessible for work. Creating these systems will undoubtedly need some resources and time, but if they’re serious about using data analytics, they can’t avoid doing so.

- Data Security: Lastly, keeping data secure becomes more crucial for any organization that works with large volumes of data. Whether data is being kept or is in transit, it needs to be protected throughout the entire data ecosystem. Therefore, think about implementing two-factor authentication, encryption, and other security measures to help stop data loss, theft, and destruction. Alternatively, go one step beyond and employ blockchain technology to combine cryptography and decentralization for an extra degree of protection.

Data Analytics Importance in Supply Chain Operations

Simply described, data analysis is the process of analyzing information with various computer software tools and applications. This information can include transportation expenses, inventory levels, supplier and customer information, and supply chain information. Regarding the analysis portion, businesses want to figure out how to save expenses while maintaining quality, expediting delivery, and optimizing inventories.

Many data points from various sources, including procurement, inventory, order coordination, warehouses, and shipping, are required for this research. Keeping track of everything is essential because numerous components move at once.

Data analytics in supply chains can yield the following benefits:

- Track Shipments More Effectively

- Ensure Minimal Downtime for Machinery

- Manage Inventories Effectively

- Streamline Operations

6 Ways to Reshape Supply Chain with Data Analytics

The concept of data analytics holds great promise to transform the supply chain management industry. It enables businesses to understand their clients and goods on a deeper level, which results in better product development, more devoted customers, and more successful marketing campaigns.

Supply chain managers can benefit from data analytics in the following ways:

1. Real-Time Shipment Monitoring

Monitoring the freight while it is in transit not only enables businesses to respond promptly to shipment problems and address them as needed, but it also offers essential information about how these kinds of supply chain interruptions might be prevented in the future. For this reason, it’s critical to collaborate with a 3PL partner that uses track and trace teams to keep an eye on the freight at every stage and provide up-to-date information on shipments as they approach their destination.

Freight monitoring supply chain analytics can be used to assess and gather data on potential bottlenecks, carrier routes, modes of transportation, traffic and weather patterns and disruptions, as well as new and existing carrier routes.

What information does this data provide?

Businesses can adjust their shipping operations with the use of transportation and supply chain analytics to:

- Decrease fuel use to support more sustainable initiatives

- Reduce delivery time

- Select the best shipping route

- Address hazards and interruptions that could proactively affect supply networks

- Reduce the price of shipping items

2. Enhanced Warehousing Efficiency

Optimal resource allocation drives efficient warehousing. Backlogged orders and congested dock doors stall operations. Data collection eases congestion, streamlines warehouse flow, and ensures timely deliveries. Streamlining processes conserves resources and promptly fulfills orders, boosting overall efficiency.

In addition to demand forecasting and inventory management, there are other crucial metrics to monitor that can provide businesses with useful information:

- Warehouse Layout & Product Movement: Relocating and organizing specific objects’ storage locations can help shorten the time it takes to find and retrieve them. The routes that warehouse employees follow to collect, pack, and deliver goods to loading bays can all be made more efficient by doing this.

- Order Picking Speed: Pinpointing the problems that are causing pick and pack times to lag, can help businesses optimize their fulfillment procedure.

- Labor Management: This can aid in the most efficient use of labor resources when it comes to scheduling and hiring.

3. Demand Forecasting

Optimizing the supply chain requires effective inventory management. For suppliers, popular product overstocks or stockouts can be a nightmare. If organizations can’t satisfy a customer’s request at the appropriate time, they risk losing business to alternative suppliers. Advanced demand forecasting in inventory management with supply chain analytics can improve productivity across several activities.

According to 36% of supply chain experts, the main reason for implementing analytics was to optimize inventory management to balance supply and demand. Actionable insights are produced by real-time monitoring of inventory, retail sales, and product movement data. These insights can assist businesses in setting prices, planning product promotions, and optimizing incoming and outgoing deliveries.

By using automated stock counts to improve inventory management and deliver inventory based on consumer preferences and location, businesses may lower distribution costs optimize budgets, and forecast how much inventory to keep on hand. Achieving the ideal equilibrium between supply and demand ensures that clients receive services and products on time and with minimal lead time.

4. Predictive Maintenance

Businesses can perform predictive maintenance to reduce downtime and enhance safety in the manufacturing process by evaluating data from devices and systems that are integrated with artificial intelligence, machine learning, and the IoT (Internet of Things). The goal of predictive maintenance is to identify potential equipment breakdowns and enhance preventive maintenance programs by analyzing historical and current data.

- Predictive maintenance optimizes equipment upkeep, addressing issues as they arise.

- This approach minimizes unnecessary maintenance, cutting costs for spare parts and supplies.

- It slashes downtime by ensuring equipment receives maintenance only when necessary, preventing disruptions in production and supply chain bottlenecks.

By proactively managing maintenance needs, resources are conserved, and operations run smoothly, enhancing overall efficiency.

5. Improve Revenue & Retailer Satisfaction

Analytics can assist with pricing, promotions, and product placement by giving information on the balance between supply and demand across various retail locations. Organizations can better plan their sales and marketing strategies to boost revenue and keep consumers by considering consumer behavior, demographics, and other trends and patterns.

Businesses can calculate demand based on location, seasonality, and weather conditions with the use of data analysis at the point of sale. Retailers can use this data to better understand their customers’ usage patterns and purchasing habits, as well as to detect slow-moving stock and cross-sell it, set product inventory minimums, minimize product recalls, and prepare for peak periods.

6. Supply Chain Data Visualization

Supply chain data visualization employs various technologies to illustrate material and product movement. Geographic flow diagrams depict shipping origins, storage, and destinations. Product flow diagrams detail material quantities per product unit, production rates, and task durations. These visualizations offer insights into supply chain dynamics, facilitating informed decision-making and enhancing operational efficiency.

The visualization of supply chain data can provide information on how long it takes for things to arrive at their destination, how much inventory is left, where there are delays or issues with the movement of goods, and how much money is lost because of subpar procedures or ineffective management. Data visualization for supply chains is displayed using tables, graphs, flowcharts, Gantt charts, and time series.

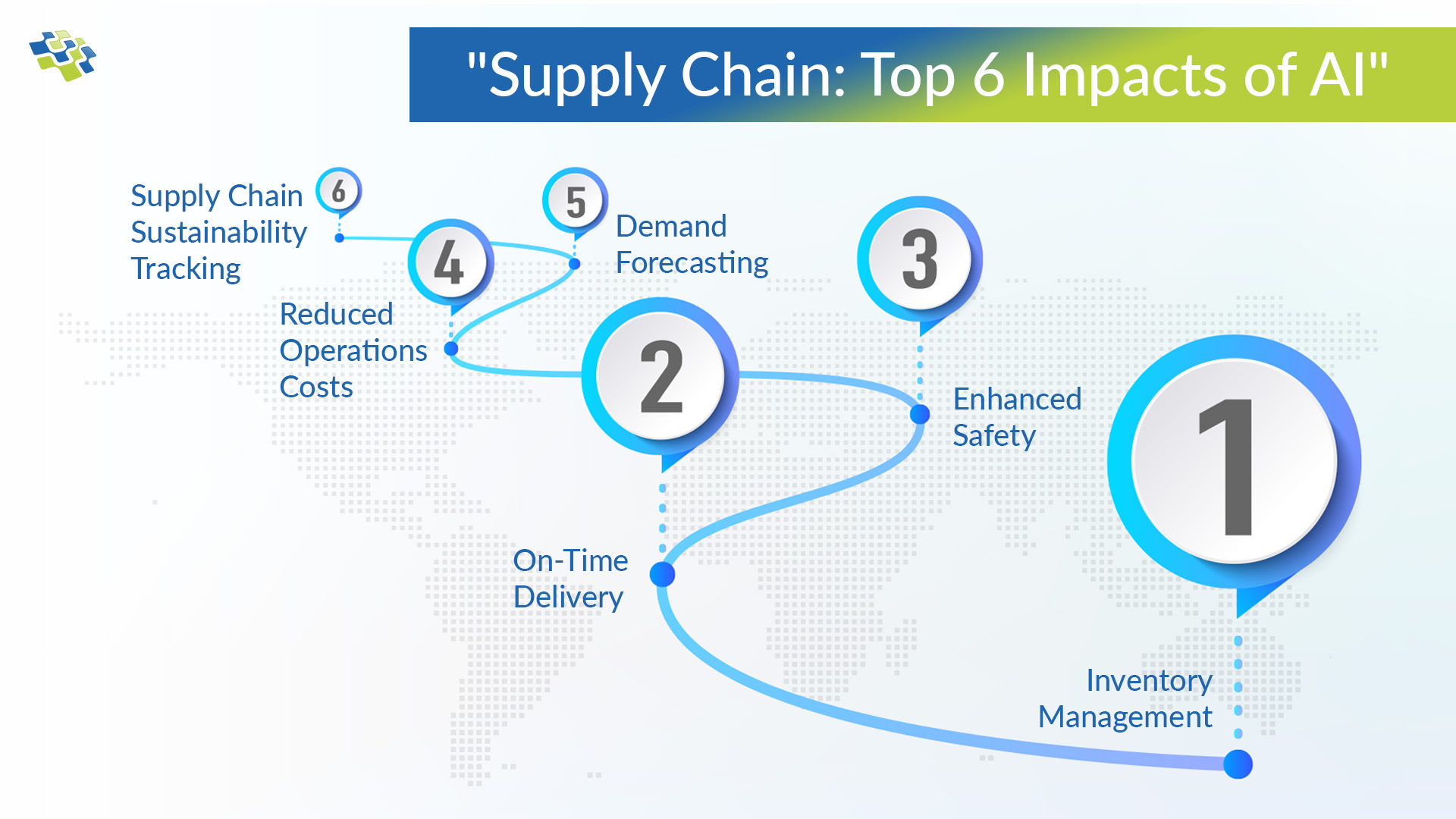

Future Trends of AI/ML and Data in Supply Chain Analytics

AI and machine learning are poised to transform supply chain optimization. These technologies offer unprecedented potential for swift and accurate data analysis on a massive scale. By identifying patterns and correlations in supply chain data, machine learning algorithms empower predictive analytics for demand forecasting, inventory management, and dynamic pricing strategies. Real-time data updates enable AI-driven systems to autonomously make decisions, enhancing supply chain agility and responsiveness to market changes. Additionally, the integration of IoT data enables proactive issue detection, reducing delays and improving overall operations. This constant stream of data allows organizations to optimize operations, ensuring product quality and safety.

The incorporation of AI and machine learning facilitates adaptive supply chains capable of swiftly adapting to unforeseen disruptions and market shifts. By proactively detecting and resolving issues, these technologies drive efficiency, reduce delays, and enhance the overall performance of supply chain operations, positioning organizations for success in dynamic and competitive markets.

How NextGen Invent Drives Data Analysis for Supply Chain Optimization?

In today’s fiercely competitive market, the adoption of data-driven strategies through supply chain data analytics services isn’t just beneficial—it’s imperative. NextGen Invent leads the charge in seamlessly integrating advanced analytics into supply chain management, developing tailored software solutions that precisely align with your organization’s unique needs and challenges.

- Our team specializes in harnessing the latest tools and technologies, ranging from predictive analytics for demand forecasting to AI-driven insights for risk management.

- By partnering with NextGen Invent, you’re not just investing in a software development service provider—you’re investing in a transformative future where data serves as a strategic asset.

- Our expertise enables you to optimize inventory, streamline logistics, and gain comprehensive insights into your operations.

Let NextGen Invent be your trusted supply chain data analytics software development services partner on the journey to a more data-driven future. Contact us to unlock the full potential of your supply chain and ensure sustained success and resilience.

Related Blogs

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then instantly evaluate the information to deliver insights.

Everything Businesses Need to Know About Warehouse Management Systems

Warehouse and distribution tasks need to be optimized, monitored, and managed by any large, complex logistics or supply chain company. These responsibilities include inventory management, order processing, and dock scheduling.

How AI Is Impacting Supply Chain Management?

Industry experts are certain that AI in supply chain management will “change the game”. It is rapidly emerging as a transformative technology, with the ability to process vast amounts of operational data generated by a range of sources, including cloud-based applications and sensors.

Stay In the Know

Get Latest updates and industry insights every month.