Why Does Supply Chain Digital Transformation Matter?

The supply chain has also not been untouched by the air of digital transformation. Gartner’s Insights suggests that integration with digital supply chain solutions can result in a 20% revenue boost and a 50% reduction in operational costs.

Want to Streamline Supply Chain Operations and Enhance Visibility? Let AI-Driven Supply Chain Digital Transformation be Your Solution Today

“Companies are planning significant strategic changes to the configuration and operation of their supply chains. When surveyed senior supply-chain executives from across industries and geographies, 93% of respondents said that they intended to make their supply chains far more flexible, agile, and resilient.”– Mckinsey

Overview of Supply Chain Digital Transformation

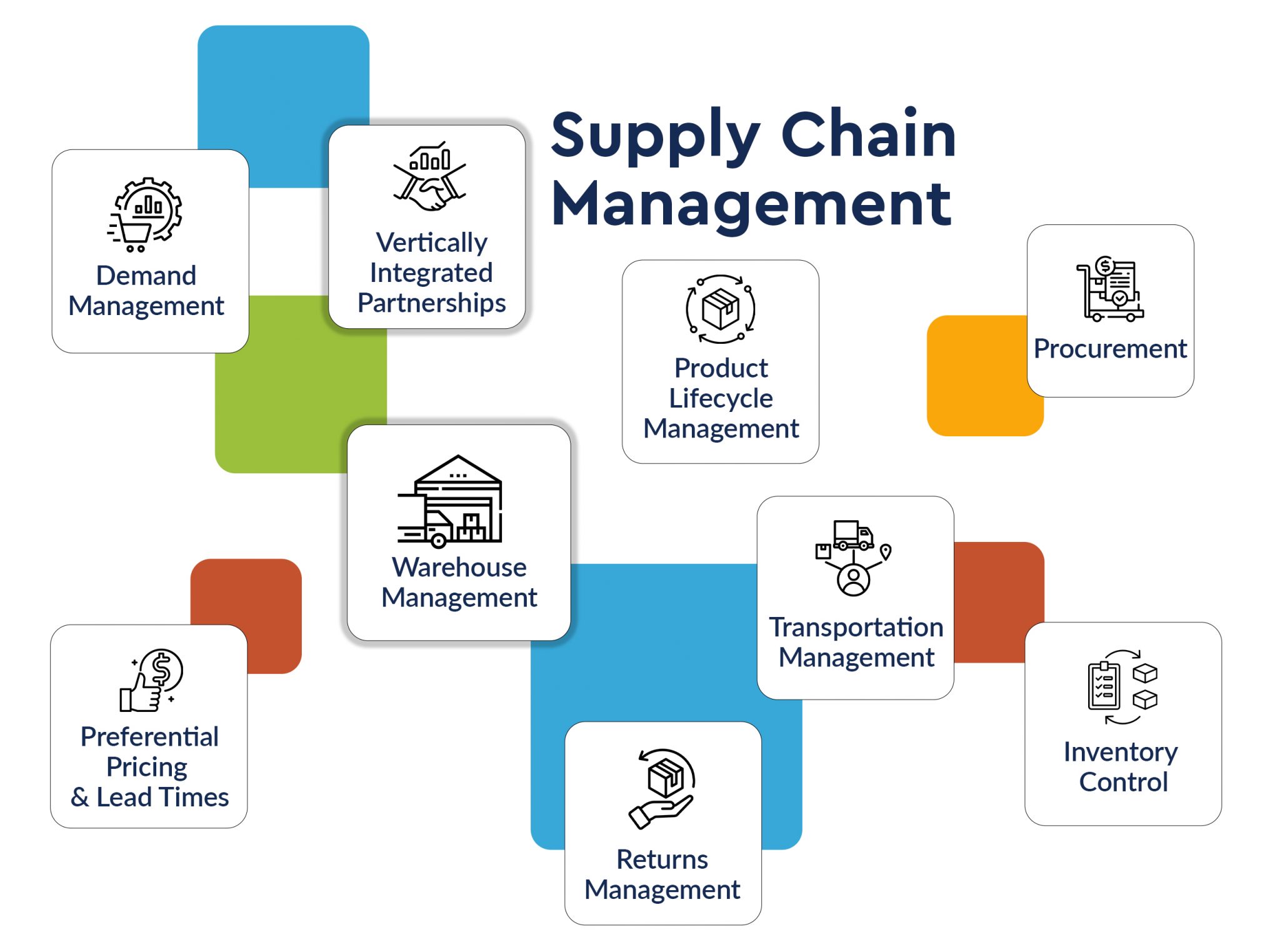

The term “digital transformation” describes a change in supply chain management where businesses leverage cutting-edge digital technologies to create a networked supply chain, connect individuals and processes throughout the chain, and combine data from various systems, locations, and organizations. This procedure lowers costs for all parties involved while generating a supply chain that is more nimble, transparent, and efficient, allowing customers to get orders more quickly.

According to McKinsey research, companies that vigorously digitize their supply chains can anticipate a significant increase in annual growth of earnings before interest and taxes, with a rise of 3.2%, the highest among all business areas examined. Moreover, they can expect an annual revenue growth increase of 2.3%.

Real-time connectivity in digitalized supply networks facilitates seamless communication and cooperation between partners, increases supply chain visibility, and supports intelligent supply chain optimization.

Traditional vs Digital Supply Chains

Let us compare and check what is lacking and point where the digital supply chain makes master moves.

- The traditional version relied more on transactional data, whereas the digital version leverages real-time information using robotics and AI in the supply chain.

- Traditional supply chain follows a linear model, but in the digital version, IT and operational technology systems are integrated.

- Where in the traditional version information is often siloed within departments which can hinder collaboration and communication across the supply chain. While the digital version integrates the data from various departments, promoting collaboration and data-driven decision-making.

- Flexibility experience is minimal while going down the traditional lane. It follows a linear structure and is restricted to adapting to the ever-changing market demands. Whereas digital supply chain management adopts agility and flexibility and allows quick adjustments to changing customer and market demands.

Issues to Be Resolved Through Digital Transformation in Supply Chain

Here are four common supply chain issues and potential solutions through digital transformation:

- Inventory Management: Inventory management can lead to losing track of business workflow. Overstocking or stockout, resulting in increased carrying cost or loss of sales opportunities. Implementing an inventory management system, powered by RFID, IoT, and AI-based supply chain management can provide real-time visibility into inventory level. This enables proactive decision-making and optimizing stock levels.

- Supplier Communication & Collaboration: Manual and fragmented communication with suppliers can lead to delays, errors, and inefficiencies in the supply chain. However digital platforms such as supplier portals, collaborative software, and blockchain can improve collaboration, transparency, and communication with suppliers.

- Demand Forecasting Accuracy: Inaccurate demand forecasting results in underproduction, leading to excess inventory or stockouts. With advanced analytics, machine learning supply chain algorithms, and historical data, companies can enhance demand forecasting accuracy, identify demand patterns, and anticipate changes in customer demand more effectively.

- Transportation Optimization: Inefficient transportation routing and scheduling lead to high logistics costs and longer lead times. Implementing transportation management systems (TMS) powered by algorithms and optimization techniques can optimize routes, consolidate shipments, minimize empty miles, and improve delivery accuracy. A cost-effective and time-saving solution.

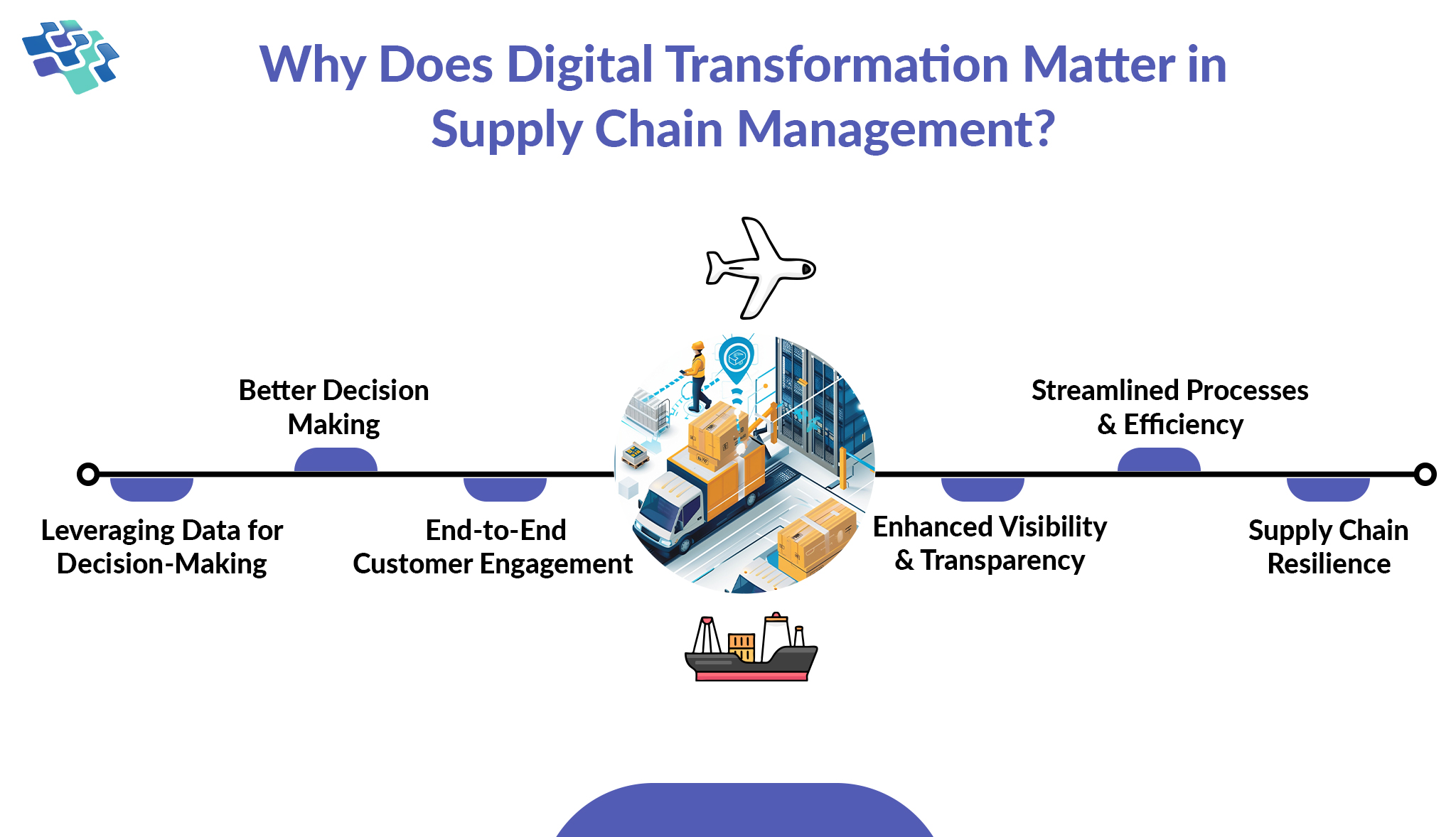

Why Does Supply Chain Digital Transformation Matter?

The integration of digital transformation in supply chain management facilitates collaboration, automation, and efficient use of analytics for your planning, sourcing, and logistics teams. It has also been shown to maximize expenses, reduce risk, and promote growth. Now, it’s time to unveil the reasons that will help you understand the importance of digital transformation in supply chain solutions.

1. Leveraging Data for Decision-Making

1. Leveraging Data for Decision-Making

Digital transformation in supply chain grants businesses access to a wealth of data for informed decision-making. Leveraging data analytics and machine learning algorithms, businesses glean insights into consumer behavior, industry trends, and supply chain performance.

- Optimizing inventory levels and reducing carrying costs becomes feasible by identifying customer order trends through data analytics.

- Businesses pinpoint process inefficiencies or cost-saving opportunities. For example, analyzing production data can reveal bottlenecks, prompting operational enhancements.

Proactive measures to meet consumer expectations and mitigate risks are attainable through predictive analytics, which forecasts future demand and potential disruptions. Through active utilization of data, businesses not only enhance operational efficiency but also adapt swiftly to market dynamics, ensuring sustained competitiveness.

2. Better Decision Making

Integrating digital technologies into the supply chain enables businesses to swiftly and astutely decide on each function. By amalgamating transactions and information on a macro scale, precise performance monitoring becomes feasible, allowing for timely adjustments to mitigate the distortions caused by average costs. With digitalization, businesses can operate with agility and accuracy, reacting promptly to market dynamics.

According to a recent study businesses embracing digital supply chain solutions experience up to a 30% increase in operational efficiency. Active monitoring and adjustment ensure that businesses remain responsive and competitive in today’s fast-paced markets.

3. End-to-End Customer Engagement

Digital transformation will enhance customer engagement in supply chain management processes. For example, clients can actively engage with a supplier’s automated tracking system to receive real-time updates on their orders until delivery. This ensures that consumers perceive greater value in their brand experience, feel empowered, and exercise more control over their purchases.

- Digital platforms enable interactive communication between customers and suppliers, fostering transparency and trust.

- Another scenario involves customers accessing online portals to customize their orders, providing personalized experiences tailored to their preferences.

- As a result, customer satisfaction and loyalty are bolstered, driving repeat business and positive word-of-mouth.

By actively involving customers in the supply chain journey through digital tools and platforms, businesses not only enhance customer experience but also gain valuable insights for continuous improvement and innovation.

4. Enhanced Visibility & Transparency

Digital transformation brings about heightened transparency and visibility in the supply chain, offering organizations real-time insights into operations. Utilizing digital tools and technologies, businesses can effortlessly monitor product movement, track inventory levels, and identify potential delays or bottlenecks. For instance, IoT devices provide real-time data on the whereabouts and condition of items during transit, enabling swift response to any issues and informed decision-making.

Enhanced visibility facilitates more accurate demand forecasting, reducing the risk of stockouts and overstock situations. Additionally, digital platforms enable seamless collaboration and information sharing among supply chain partners, fostering efficiency and agility. Ultimately, increased transparency and visibility empower organizations to optimize operations, minimize risks, and deliver superior customer experiences in the dynamic marketplace.

5. Streamlined Processes & Efficiency

Supply chain digital transformation streamlines internal business activities through automation, significantly reducing errors and operating expenses. For example, repetitive tasks like demand forecasting, inventory management, and order processing are automated, leveraging tools such as robotic process automation (RPA) for tasks like data entry. This boosts productivity and accuracy while freeing up valuable human resources.

Digital integration of applications and supply chain systems eliminates manual data entry, ensuring seamless information flow across departments. Another example involves using machine learning algorithms to optimize routing and scheduling in logistics, enhancing efficiency and reducing delivery times. Ultimately, automation and integration lead to a more responsive and flexible supply chain, capable of meeting evolving market demands with agility and precision.

6. Supply Chain Resilience

Digital transformation in the supply chain revolutionizes operations for many companies, presenting a seamless and transparent workflow. Utilizing digital platforms and cloud-based systems, organizations swiftly adjust to market fluctuations, supplier issues, and unexpected events. This adaptability fosters trust between customers and service providers, as processes become easily trackable and transparent. For instance, real-time tracking systems ensure visibility throughout the entire supply chain, enhancing customer satisfaction and loyalty.

Moreover, digital tools enable predictive maintenance in manufacturing, reducing downtime and enhancing efficiency. Ultimately, these solutions bolster resilience, allowing businesses to maintain operations, minimize disruptions, and fulfill customer needs even amidst challenging circumstances.

Refer to Our Podcast for Further Details:

Leveraging AI/ML Solutions for Supply Chain Optimization

What Does the Future of Digital Supply Chain Offer?

As the world embraces digitalization, the future of supply chain management is poised for significant evolution. Explore some cutting-edge digital transformation supply chain trends below:

- AI & Automation: As AI adoption grows in digital supply chains, challenges will arise alongside increased automation. Automated technologies will simplify tasks like order fulfillment, transportation, and warehouse management. AI-driven algorithms will monitor emissions, predict demand fluctuations, and optimize processes for enhanced efficiency.

- Real-time Data Utilization: Embracing real-time data analytics emerges as a pivotal trend in supply chain management. Technological advancements enable the swift collection and analysis of vast datasets. From optimizing inventory levels to refining delivery routes, real-time data ensures operational efficiency remains at its peak.

- Greater Supply Chain Resilience: Building resilience is essential to address both routine and severe disruptions. Despite recent challenges, blockchain technology holds significant potential. Anticipate a continued digital shift by 2025, particularly in supply chain financing, contract management, and tracking and tracing processes.

How NextGen Invent Helps in Supply Chain Digital Transformation?

No matter how and what led to the digitalization of almost everything, it worked for the best. Digital supply chain solutions have resolved the issues that changed the whole prospect of the business’s workflow as well as the supply chain journey. The intervention of AI, ML, robotics, and IoT has efficiently enhanced transparency, agility, flexibility, and accuracy to its peak. But this is not just a dead-end. The future of digital SCM holds a lot more promises that will further escalate the standards of perfection.

Experience seamless supply chain digital transformation with NextGen Invent’s end-to-end supply chain software development services. Our developed solution empowers businesses to efficiently manage transportation, distribution, routing, deliveries, and more. With our skilled and experienced resources, we can deliver solutions that can escalate your business performance. Enjoy 100% visibility and control over operations, along with significant benefits like a 12% reduction in freight costs, a 64% increase in customer experience, and a 34% decrease in incidental expenses.

We empower businesses to embrace digital transformation, optimize their supply chain operations, and achieve sustainable growth in the dynamic marketplace. With our supply chain services, businesses gain a comprehensive view of their supply chain, enabling proactive management and swift response to contingencies.

Contact us now to streamline your supply chain operations and drive growth.

Related Blogs

How Does Supply Chain Management System Work & Its Roles

Logistics and supply chain management systems are vital enterprise solutions offering numerous use cases like cost savings, workflow optimization, and enhanced communication. A report estimates that the supply chain management industry will grow at a CAGR of 10.7%.

How to Overcome Challenges in Implementing AI in Supply Chain?

This blog endeavors to delve into these challenges, offering insights into AI services and strategies to address them effectively. Businesses can fully utilize AI in supply chain management by overcoming these obstacles and streamlining workflows to increase productivity.

How Do Businesses Optimize Supply Chain with Data Analytics?

In the modern ecosystem, efficient supply chains are critical for business success. Surprisingly, only 27% of companies utilize technology to enhance their supply chain operations. The inquiries from businesses are as follows: How to optimize labor costs? How to determine the best ways to distribute and warehouse inventory?

Stay In the Know

Get Latest updates and industry insights every month.

1. Leveraging Data for Decision-Making

1. Leveraging Data for Decision-Making