Why is Supply Chain Resilience Important All Year Round?

Additionally, the interview highlighted best practices from leading companies and the transformative role of artificial intelligence/machine learning and Generative AI technologies in enhancing supply chain resilience.

Transform Your Supply Chain with our AI-Driven Solutions to Mitigate Disruptions & Enhance Resilience

“It is critical that commitment to supply chain resilience remains a key part of resilience strategies going forward, and practitioners will need to continue to showcase the importance of this to those at the senior management level, so lessons learned from the pandemic can be applied to new challenges in the near future.”– BCI

Importance of Supply Chain Resilience & Its Relevance in Today’s Business Market

Supply chain resilience is crucial in today’s volatile business market, where disruptions can arise from geopolitical tensions, natural disasters, pandemics, and cyber-attacks. Resilient supply chains ensure:

- Continuity and adaptability,

- Allowing businesses to maintain operations and

- Meet customer demands despite unexpected events

Even minor disruptions can cascade in a highly interconnected global economy, causing significant delays and financial losses. Therefore, resilient supply chains are vital for minimizing risks, reducing downtime, and maintaining competitive advantage.

They also enhance a company’s ability to respond swiftly to market changes and emerging opportunities, ensuring long-term sustainability and growth. As businesses increasingly rely on complex, global networks, prioritizing supply chain resilience becomes indispensable for stability and success.

In-Depth Discussion on Supply Chain Resilience: Key Insights from Industry Experts

Deepak Mittal posed six pivotal questions about supply chain resilience, to which Duane Kotsen provided insightful and comprehensive answers. Their discussion covered the importance, current challenges, risks, best practices, technological advancements, and future trends in supply chain management.

Deepak Mittal: As per McKinsey, supply chain disruptions now occur every 3.7 years on average and can result in significant financial losses. Given this context, what is supply chain resiliency and why do you believe the importance of supply chain resiliency cannot be overstated?

Duane Kotsen: When discussing supply chain resiliency, it’s important to recognize that many companies fail to allocate sufficient time for upfront planning against potential disruptions. Numerous reports and materials, such as those by McKinsey, highlight this issue. The challenge, however, is that many companies do not invest sufficient time in upfront planning to address potential disruptions. I want to highlight the numerous dynamic factors influencing supply chains, including societal changes and natural events, which are accelerating at an unprecedented pace. Relying on the status quo will not fortify supply chains for the future.

- An illustrative example is the experience during the Great East Japan earthquake in 2011. The event, registering 9.0 on the Richter scale, caused substantial disruption, with estimated damages of $235 billion and long-lasting supply chain challenges.

This incident underscored the need for effective risk management tools, as evidenced by the surge in demand for supply chain risk analysis software. However, once immediate issues were resolved, interest in supply chain resilience waned.

- Fast forward to the last few years, the COVID-19 pandemic starkly exposed how unprepared many businesses were, lacking contingency plans to manage supply chain disruptions. For instance, the semiconductor shortage severely impacted automobile manufacturing.

The lesson is clear: relying on the status quo is insufficient and the environment is constantly evolving, and businesses must prioritize developing robust contingency plans to ensure their supply chains remain resilient.

Deepak Mittal: 75% of companies experienced supply chain disruptions due to the pandemic. Considering these ongoing vulnerabilities, do you think we are truly back to normal, or are there underlying issues still at play?

Duane Kotsen: “People are eager to return to what they perceive as “normal,” but I believe that the concept of normality is evolving and may never return to its previous state.”

The world today is vastly different from even five years ago, necessitating innovative approaches to planning and resilience. While global piracy has decreased over the past decade, specific groups still cause significant delays in shipping.

- For instance, the U.S. and the U.K. seem less inclined to maintain their historical role as global maritime enforcers, impacting the security of international shipping routes.

- Environmental factors further complicate the situation. The 2024 hurricane season is predicted to be particularly severe, with 150% to 200% more hurricanes than usual.

These natural disasters not only threaten coastal cities with major ports but also add another layer of unpredictability to global supply chains. Mother Nature’s increasing unpredictability, exacerbated by global warming, necessitates thoughtful consideration in supply chain planning. Demographic shifts and declining labor forces in key manufacturing regions also pose significant challenges. From 2000 to 2010, labor costs rose by over 15% annually, and even after 2010, they continued to increase by 10-12% each year. These rising costs are prompting shifts in manufacturing locations, potentially signaling a broader trend toward de-globalization.

Leaders must plan for this new reality, developing robust contingency plans and exploring alternatives to ensure success and mitigate challenges. The emphasis should be on adaptability and proactive planning to navigate the increasing complexities of global supply chains.

Deepak Mittal: Supply chain disruptions can lead to a 62% decline in customer satisfaction and a 41% drop in shareholder value. So, could you elaborate on the specific risks businesses face when their supply chains are not resilient?

Duane Kotsen: Several recent examples illustrate the significant risks businesses face when their supply chains lack resilience.

- For instance, a disruption in the Red Sea forced some shipping routes to detour around Africa, adding weeks to their journey. This caused a major Tesla plant in Germany to shut down for two weeks, affecting 11,000 employees and halting production of 12,000 cars. The estimated cost of this disruption was over a quarter billion Euros (€) in lost sales.

- The impact of such disruptions is not limited to individual companies. The cost to move goods to the West Coast of the U.S. from international destinations increased by 38%, and to the East Coast by 21%. These substantial freight cost increases are often not fully passed on to consumers, squeezing manufacturers’ margins. Additionally, freight hedging mechanisms were overwhelmed, limiting options to manage these costs.

- Retail giants like Walmart and Target experienced shipment delays due to port congestion, reminiscent of the COVID-19 pandemic when ports like Los Angeles were clogged with ships waiting to unload. During that period, the cost of moving a container from China to the U.S. skyrocketed from $1,500 to $25,000, contributing to inflation as companies struggled to absorb or pass on these costs.

Supply chain disruptions also lead to mismatches in inventory, either causing overstock, which incurs additional storage costs, or stockouts, which drive customers to competitors and potentially change their long-term buying habits. Regulatory compliance issues further complicate the situation. Industries like pharmaceuticals face stringent regulations, and any delays can result in severe penalties. The overall result is a supply chain that, despite being lean and efficient in stable times, becomes highly vulnerable to variability.

Deepak Mittal: 87% of organizations with high supply chain resiliency also report better financial performance. Could you share some best practices from these leading companies?

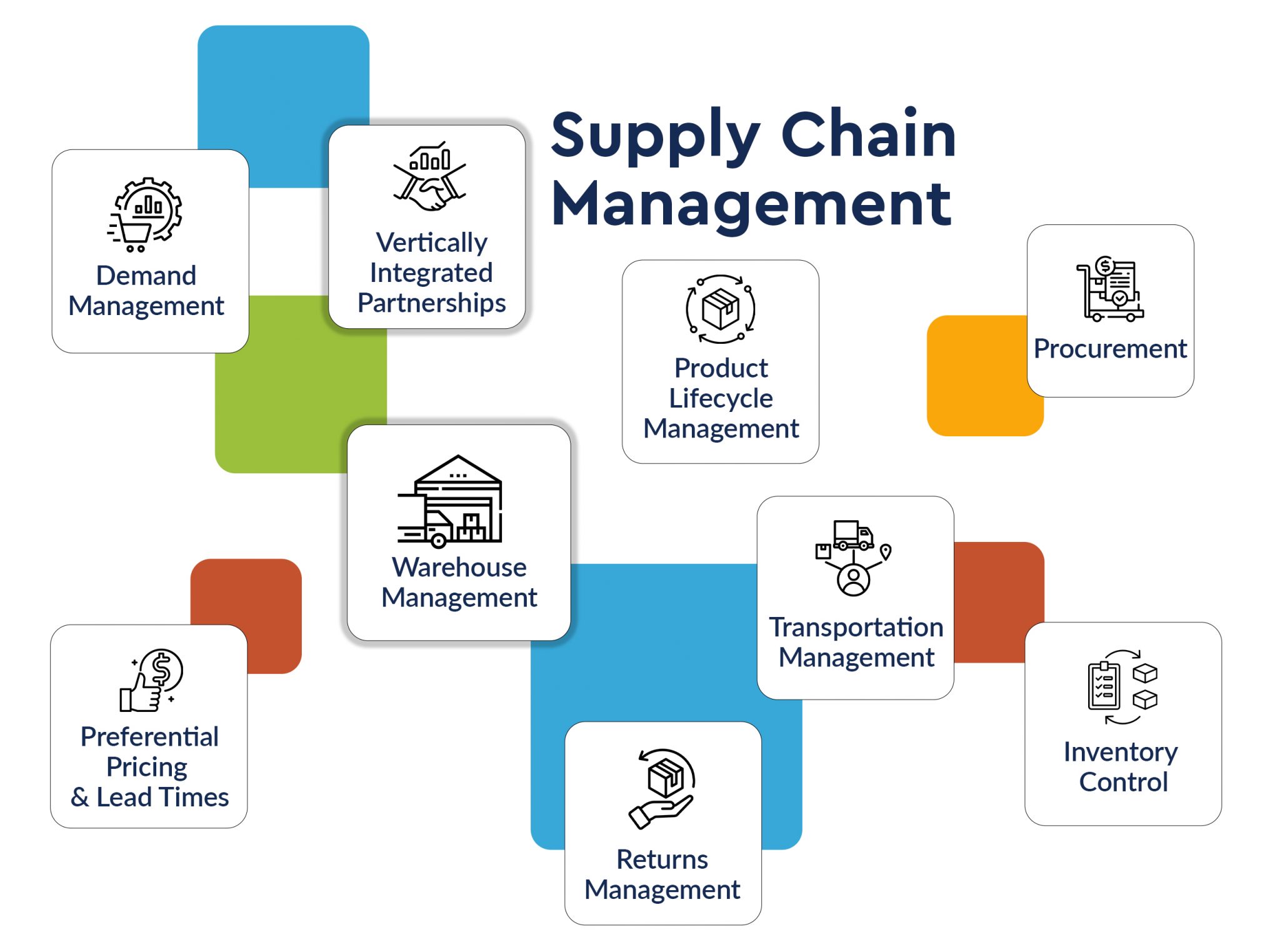

Duane Kotsen: Today, this extends beyond understanding internal operations to encompass knowing customers, and suppliers, and comprehensively assessing company strengths and weaknesses.

- Firstly, it’s crucial for companies to meticulously track product movements across various locations using aggregated point-of-sales data. This enables the creation of supply chain maps, identifying dependencies, bottlenecks, and potential failures. Mapping includes sub-components and scrutinizes suppliers’ supply chain resilience, critical for mitigating risks.

- Companies should consider multi-sourcing and geographic diversification to avoid dependency on single suppliers or regions. This approach supports resilience against disruptions like transportation bottlenecks or geopolitical tensions.

- Equally important is nurturing robust supplier relationships. Understanding suppliers’ financial stability, production capabilities, and supply chain resilience enhances overall stability and continuity. These partnerships are integral extensions of our brand.

- Lastly, implementing these practices isn’t a one-time effort but an ongoing commitment. Regular reviews—quarterly, if not monthly or weekly—are essential. This iterative approach ensures that contingency plans remain effective and adaptive to evolving supply chain challenges.

By integrating these best practices, companies can fortify their supply chains, enhance resilience, and ensure operational agility in the face of unpredictable global dynamics.

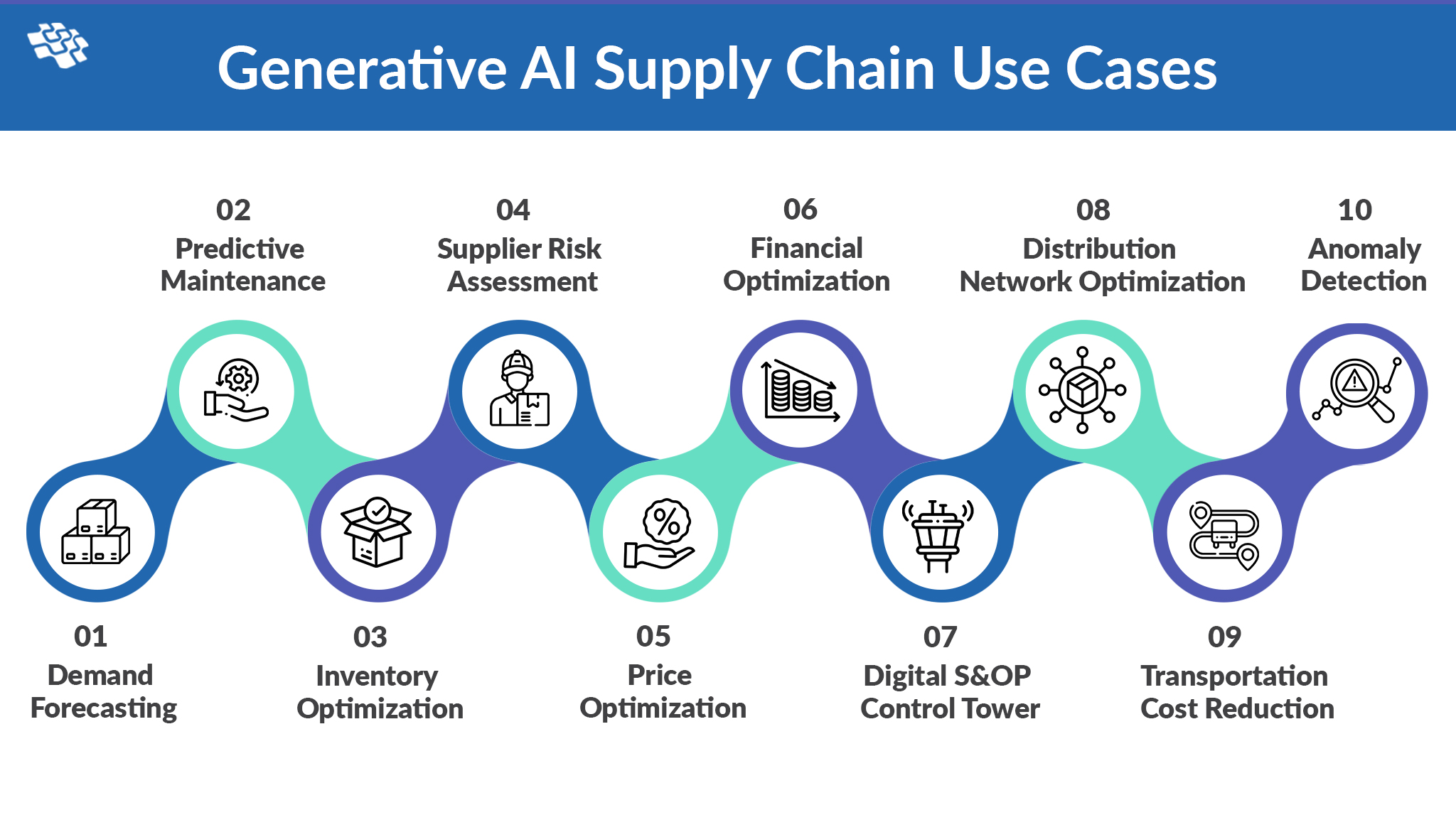

Deepak Mittal: The World Economic Forum reports that AI can reduce forecasting errors by 20% to 50% and inventory reductions by 20% to 30%. Could you share a few examples of companies and how these technologies integrate into supply chain processes to enhance resiliency?

Duane Kotsen: In discussing the role of advanced technologies in enhancing supply chain resilience, I’ve had the privilege of working closely with several exemplary companies, such as Procter & Gamble (P&G), Walmart, and Unilever. These industry leaders employ sophisticated strategies that leverage AI/ML and Gen AI technologies to fortify their supply chains.

- P&G prioritizes robust supplier assessments through regular audits and diversified networks. They utilize complex and advanced planning systems to integrate demand forecasting and inventory management, constantly updating these systems to adapt to market dynamics. Notably, P&G has implemented a digital twin technology, enabling scenario simulations for proactive planning against disruptions.

- Walmart conducts frequent reviews of supply chain operations and employs real-time tracking alongside automated technologies in their warehouses. They utilize robotic systems for efficient product movement and employ advanced software routing to optimize transportation costs and ensure delivery reliability. Walmart’s strategic focus includes maintaining safety stocks and enhancing supply chain visibility through innovative technological solutions.

- Unilever integrates environmental, social, and governance (ESG) metrics into its supply chain resilience framework. They conduct regular supplier evaluations, incorporating ES&G statistics to ensure environmental sustainability. Unilever employs innovative technology for enhanced supply chain visibility and utilizes a hybrid carbon accounting methodology to reduce emissions across their supply chain, aligning with their sustainability goals.

These companies exemplify how AI/ML and Gen AI technologies are pivotal in enhancing supply chain resilience through proactive planning, real-time monitoring, and sustainability-driven practices. Their innovative approaches underscore the transformative potential of technology in mitigating risks and optimizing operational efficiencies across global supply chains.

Deepak Mittal: Do you have any concluding thoughts on the future of supply chain resiliency and any upcoming events or trends we should be aware of?

Duane Kotsen: Reflecting on the future of supply chain resiliency, there are several critical considerations to keep in mind.

Key Takeaways:

- First, it’s essential to understand that the dynamics of the past decade are evolving rapidly. Factors such as geopolitical tensions, the impact of global warming, demographic shifts, rising labor costs, and the trend toward deglobalization are reshaping the landscape of supply chain management. These changes introduce a level of unpredictability that demands proactive measures to enhance supply chain resilience.

- Another pivotal takeaway is the value of leveraging available data. Today, organizations possess vast amounts of data that, with minimal effort in data cleansing and the deployment of AI technologies, can yield significant or profound insights. Whether through off-the-shelf AI solutions or customized approaches, harnessing data analytics can significantly bolster decision-making capabilities and mitigate operational risks.

- Lastly, it’s imperative not to treat supply chain resilience as a one-time initiative but rather embed it into the organizational DNA. Establishing a regular cadence for assessing supply chain vulnerabilities, evaluating supplier relationships, and implementing contingency plans ensures readiness to adapt to unforeseen disruptions. This ongoing process of review and adaptation is crucial in maintaining agility and responsiveness.

Conclusion

The interview with both industry experts provided profound insights into the critical facets of supply chain resiliency. From defining its importance amidst evolving global dynamics to exploring best practices and integrating advanced technologies like AI/ML, each discussion underscored the imperative for organizations to fortify their supply chains against disruptions. Key takeaways include the necessity to anticipate and adapt to changing norms, leveraging data analytics for informed decision-making, and adopting a continuous improvement mindset in supply chain management. The examples shared by the experts illuminated the real-world impacts of resilience strategies, highlighting both the pitfalls of complacency and the rewards of proactive planning.

Looking ahead, our commitment to fostering knowledge exchange remains steadfast. We invite you to stay engaged with our upcoming events and discussions, where we delve deeper into emerging trends and best practices in supply chain management.

Join us in shaping the future of resilient supply chains and ensuring organizational readiness. Stay informed, stay prepared, and stay connected with us for insights that empower your business resilience journey.

Related Blogs

AI in Supply Chain: Embracing Future with Gen AI & Automation

Deepak shared his insights on the latest trends, strategic implications, and the practical applications of these cutting-edge technologies. He also provided a glimpse into the future of supply chain management, emphasizing the potential for significant advancements and improvements.

10 Most Crucial Use Cases of Generative AI in Supply Chain Industry

That explains why Generative AI in supply chain is being used more and more. A significant subgroup of AI that employs machine learning algorithms has captured business interest. Generative AI holds the potential to streamline all supply chain operations.

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then instantly evaluate the information to deliver insights.

Stay In the Know

Get Latest updates and industry insights every month.