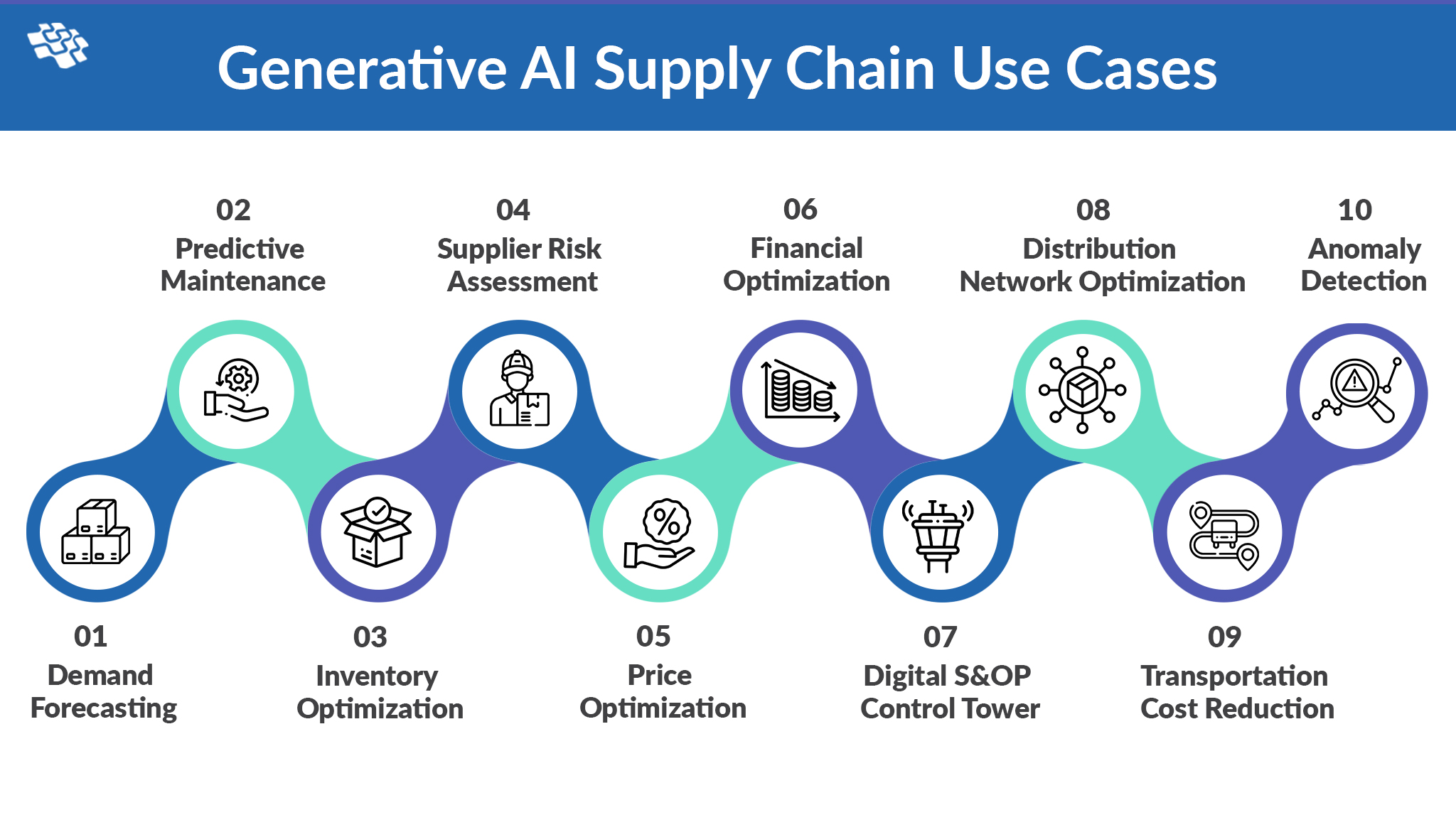

Enterprise Supply Chain Management

As an enterprise supply chain management services company, we empower organizations to modernize and scale their supply chain operations by integrating Agentic AI, autonomous planning, and data-driven decision intelligence across the value chain. Our solutions seamlessly connect asset tracking, ERP and inventory systems, SCM platforms, procurement ecosystems, and supply chain finance workflows into a unified, composable digital architecture. Ash, how about a line regarding "transparent Open Purchase Orders?

- Asset Tracking & Visibility

- Procurement & Supplier Management

- ERP & Inventory Optimization

Warehousing Tech

We modernize warehouse operations with Generative AI, robotic automation, and augmented reality to address labor shortages, rising costs, and limited visibility. By integrating digital twins, sustainable packaging, warehousing automation, and smart fulfillment, our supply chain services optimize storage, enhance picking accuracy, and create adaptive, energy-efficient ecosystems that drive end-to-end supply chain agility.

- Warehousing Automation

- Warehousing & Fulfillment

- Sustainable Packaging Solutions

Freight Tech

Our AI data scientists enhance freight operations through autonomous trucking, smart fleet management, and multimodal logistics integration to tackle delivery delays, high fuel costs, and poor visibility. Our solutions connect marine, air, rail, and trucking logistics with real-time tracking, route optimization, and predictive insights, ensuring faster, cost-efficient, and sustainable freight movement across global networks.

- Fleet Management Systems

- Trucking Logistics Optimization

- Smart Route Planning

Last-Mile Delivery

We revolutionize last-mile logistics through autonomous delivery systems, drone and electric vertical takeoff and landing (eVTOL) logistics, and real-time delivery orchestration. Our solutions address challenges such as high delivery costs, traffic delays, and inefficient routing. By integrating reverse logistics, ultrafast delivery, and automated dispatch, we enable faster, more sustainable, and customer-centric last-mile operations.

- Autonomous Delivery Systems

- Drone & eVTOL Logistics

- Reverse Logistics Solutions

Inventory Management

Our team of SCM experts empowers supply chain efficiency for global networks through our advanced inventory optimization strategy. Our comprehensive supply chain services, including inventory segmentation, planning, and material optimization, empower streamlined operations, ensuring precision in inventory levels and supply chain dynamics.

- Inventory Cost Optimization & Stock-out Prediction

- Optimal Stocking

- Slotting Recommendations

Transportation Management / Network Planning

Utilizing cutting-edge design tools, processes, and technologies, our network planning services enhance your supply chain network. Our network planning solutions strategically ensure successful route planning, reduced costs, and optimized cost in the transportation of goods, hence contributing to a cost-effective supply chain.

- Vehicle Routing

- Freight Cost Optimization

- Optimized Transportation Spend