How Does Supply Chain Management System Work & Its Roles

And this is the blog for you if your business is one of them! We will talk about how the supply chain management system works and SCM software roles in this blog.

Transform Your Supply Chain with AI-driven Solutions. Optimize Inventory and Mitigate Disruptions for Seamless Operations

“Customers in the United States are increasingly looking for supply chain management software solutions that can help them improve their operational efficiency, reduce costs, and enhance their overall supply chain performance. They are also looking for solutions that can provide real-time visibility into their supply chain operations, enabling them to make informed decisions and quickly respond to changing market conditions.”- Statista

Supply Chain Management System Process Overview

A startling 79% of businesses with improved supply chain skills see revenue growth that is noticeably higher than typical, according to Deloitte. This demonstrates why the importance of a well-managed supply chain cannot be disregarded. The planning, sourcing, and distribution processes are just a few of the associated tasks that make up the supply chain management process. The smooth transfer of goods and services from the point of origin to the customer is made possible by these actions.

Various steps, such as planning, sourcing, production, logistics, and distribution, must be coordinated and managed. All the stages involved in supply chain management are essential to ensure prompt delivery and client contentment. Smooth operations are made possible by a well-coordinated process, which includes managing transportation, choosing suppliers, supervising production, and estimating demand.

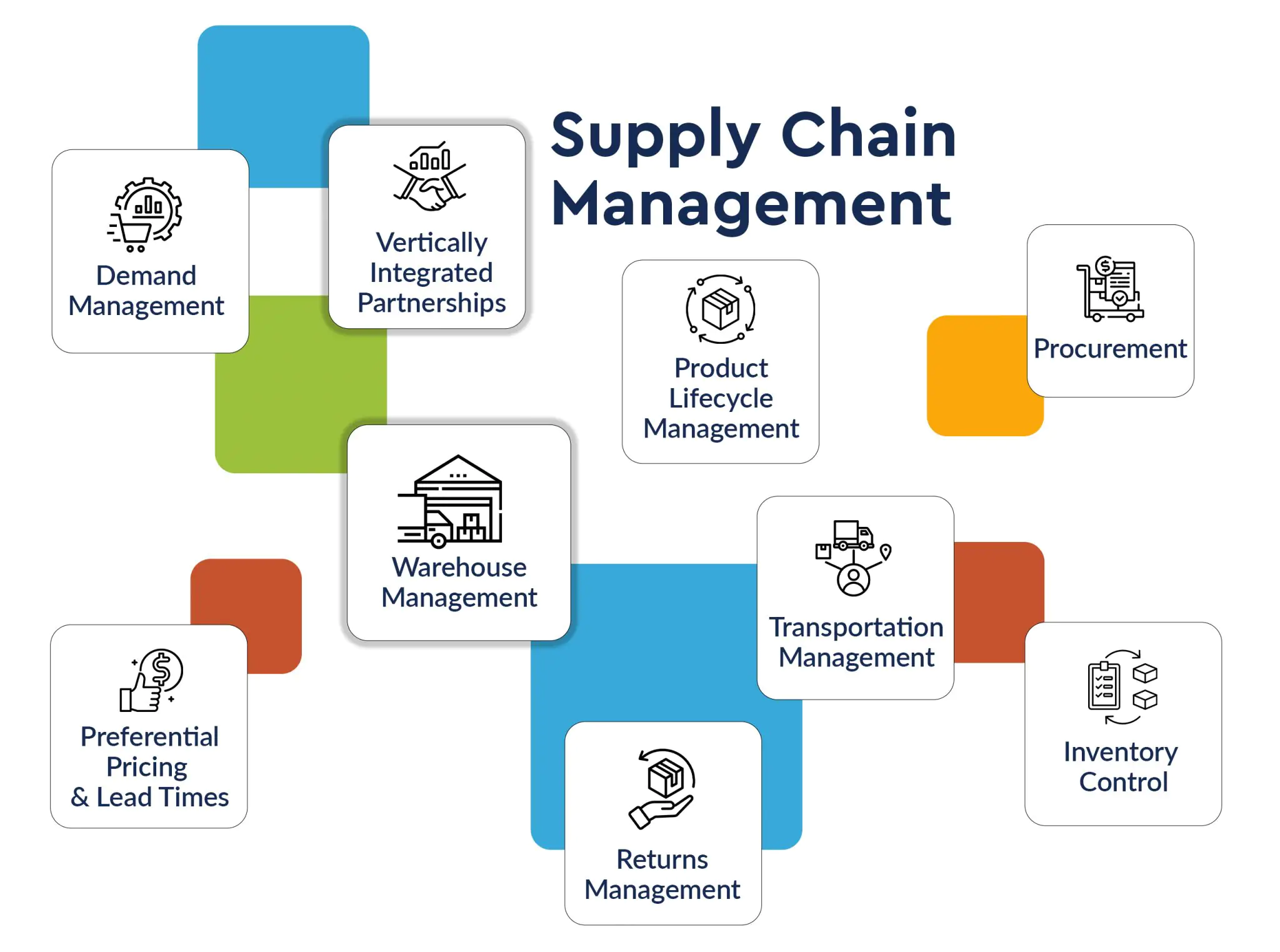

Role of Supply Chain Management System Software

Effective supply chain management is the foundation of any successful company. Additionally, software is essential to simplify and optimize this intricate process. Here’s how:

- Efficiency & Automation: Supply chain system software efficiently automates tasks such as order processing, demand forecasting, route optimization, and warehouse management. It reduces errors, expedites deliveries, optimizes production, saves time and fuel with efficient transportation routes, and enhances accuracy and speed in warehouse operations.

- Risk Management & Compliance: System software mitigates supply chain risks by monitoring regulatory compliance, tracking product recalls, and managing supplier risks. It ensures adherence to safety, environmental, and labor laws, responds promptly to safety incidents, and identifies/mitigates risks associated with suppliers, enhancing overall supply chain resilience.

- Delivery & Customer Service: ERP software determines optimal packaging and quality control criteria for shipping products. It maintains a centralized database for shipment details, enabling businesses to log, track, and update shipping processes automatically. Employees and customers can easily track orders and deliveries. Additionally, ERP generates and sends invoices upon shipment, enhancing customer experience and enabling flexible, personalized production.

- Inventory Management: Omnichannel retailers prioritize inventory management due to its critical impact on supply chains and customer satisfaction. Integrating ERP with a supply chain management system grants seamless access to inventory data across platforms, ensuring lean inventory levels. This allows real-time tracking of production resources and shipments. Furthermore, integrated solutions enhance supply and demand management, improving forecasting accuracy for retailers.

How Does Supply Chain Management System Work?

The SCOR model, focusing on the 5 stages of SCM, guides efficient operations. Planning establishes strategy, while subsequent stages ensure execution. Proficiency in all areas is essential to prevent bottlenecks and enhance overall efficiency in your business’s supply chain.

1. Planning

Planning is the initial step in the supply chain management process that decides how to allocate the resources to fulfill demand and keep costs as low as possible. Establishing guidelines for gauging and enhancing productivity is part of it. Accurately projecting the resources required to meet future customer demand is the primary objective of supply and demand planning. The next step is to set aside funds and put systems and procedures in place to ensure that they meet your anticipated needs.

Businesses can manage their supply volumes and costs more effectively than their competitors by controlling the bullwhip effect, which is another benefit of careful supply planning. Key supply chain metrics are necessary to monitor your supply chain management effectiveness once it is underway.

2. Sourcing

Sourcing within supply chain management involves the procurement of goods and services. Ineffective sourcing can lead to escalated material expenses, production or delivery delays, and scarcity of raw materials or components. Its primary objective is to establish dependable and cost-efficient supply chains. Core sourcing activities include monitoring supplier performance and pricing to ensure optimal arrangements. Although specific requirements vary across industries.

Supply chain management system sourcing typically entails verifying that:

- Raw materials meet manufacturing specifications

- Vendor pricing is competitive

- Vendors offer flexibility for unforeseen events, and

- Vendors consistently deliver high-quality goods on schedule

By optimizing sourcing practices, businesses can enhance supply chain efficiency and resilience. It ensures the procurement process remains agile and adaptable to changing market conditions, ultimately contributing to improved operational performance and customer satisfaction.

The supply chain sourcing process includes:

- Tracking Supplier Payments

- Managing Suppliers

- Negotiating Supplier Agreements

- Developing Sourcing Infrastructure

3. Manufacturing

At this point in the supply chain management process, businesses turn the components or raw materials they have acquired from their suppliers into something new by using their labor force and machinery. Although it is not the last phase of supply chain management, this finished product is the ultimate objective of the production process.

Sub-steps in the manufacturing process, like assembling, testing, inspection, and packing, can be separated even further.

Businesses need to be aware of waste and other variables that could lead to straying from their initial goals during the manufacturing process. For example, a business needs to address the problem or go back and review the earlier stages of supply chain management if it is consuming more raw materials than anticipated and procured because of insufficient staff training.

4. Delivery

After goods are manufactured and sales are completed, a business needs to get the goods into the hands of its clients. A business that has an efficient supply chain management system will have strong delivery networks and logistical capacities to ensure the prompt, affordable, and safe delivery of its goods. This entails having a fallback or a variety of distribution strategies in case one mode of transportation becomes momentarily unsuitable.

The movement of items along the supply chain is covered by the delivery stage. Raw material transportation is the first step, followed by manufacturing, inventory control, fulfillment, and shipment.

Among the supply chain management procedures that facilitate delivery are:

- Warehousing

- Distribution Management

- Order Management

5. Returns

The support for product and customer returns marks the end of the supply chain management process. When a consumer needs to return a goods, it might be particularly problematic if the company made a mistake. Reverse logistics is the term used to describe this return procedure, and the business needs to make sure it can accept returned goods and accurately provide refunds for them. The consumer transaction needs to be rectified, regardless of whether the company is carrying out a product recall or a client is merely dissatisfied with the product.

Returns can also be a useful source of feedback for the business, allowing it to find and fix issues with poorly made or damaged products. However, the supply chain management procedure will have failed and future returns are likely to continue if the root reason for a customer’s return is not addressed.

Future of Supply Chain Management System

Reactivity and the customer experience—understood and managed within a network rather than a linear model—are key components of the future of supply chain management systems. Each node in the network needs to be able to handle various aspects including sourcing, trade regulations, shipment methods, and more, all while being responsive and adaptable to the needs of the end user. In addition to enabling more connectivity and SCM utilization, advanced technologies will be leveraged more and more to enhance transparency and visibility across this network. The SCM planning function will grow more sophisticated to consider customer requests. It will require businesses to be flexible.

Supply chain planning used to be a sporadic commercial activity. It will continue like this in the future. Planning and execution will also be more closely aligned in future SCM systems, which is not the case for most businesses now. In SCM, the demand for precision and speed will only grow. By providing your supply chain with an intelligent SCM system, businesses can ensure that it is prepared for the future.

Refer to Our Podcast for Further Details:

The Transformative Impact of AI in Supply Chain

How to Select a Suitable Supply Chain Management Software?

Every business is different in and of itself, and the same is true of its limits and needs. As such, supply chain management varies depending on the type of firm. To obtain the highest ROI, it becomes even more important to select the ideal software solution. Custom software and off-the-shelf software are the two options available when selecting small business supply chain management softwares.

However, most businesses have more demanding needs, and custom software is required to satisfy them. Software readily available off the shelf provides a one-size-fits-all solution ill-suited to an enterprise’s needs. Therefore, businesses rely on custom software development to provide a solution that addresses their unique requirements.

With ai supply chain software development services, businesses can create unique solutions. For the best software for supply chain management, that is standards-compliant and scalable, go no further than NextGen Invent, a top enterprise supply chain management software company.

Developing the best software for supply chain management has the following advantages:

- Provides specialized functionalities to meet any unique business demands

- Totally in line with the ecology and business processes of your company

- Total command over the program, with simple backend management

Why Choose NextGen Invent as Your Supply Chain Management Software Development Company?

NextGen Invent specializes in crafting leading supply chain management software solutions, drawing from over a decade of experience in empowering businesses, including Fortune 500 companies. With deep insights into logistics, retail, finance, healthcare, and other pivotal sectors, we offer comprehensive solutions that optimize every aspect of your supply chain operations. Moreover, our commitment to data security and regulatory compliance is unwavering. Our solutions are GDPR-compliant and ISO-certified, ensuring the highest standards of security and compliance.

By partnering with NextGen Invent, you unlock a myriad of benefits. Digitizing your supply chain with our tailored solutions not only reduces costs and mitigates risks but also boosts productivity and enhances employee satisfaction. Enhance your supply chain management to new heights of efficiency and effectiveness.

If you seek a tailored SCM solution backed by technical prowess and industry experience, choose NextGen Invent today. Contact us to unlock the potential of your supply chain.

Related Blogs

How to Overcome Challenges in Implementing AI in Supply Chain?

This blog endeavors to delve into these challenges, offering insights into AI services and strategies to address them effectively. Businesses can fully utilize AI in supply chain management by overcoming these obstacles and streamlining workflows to increase productivity.

How Do Businesses Optimize Supply Chain with Data Analytics?

In the modern ecosystem, efficient supply chains are critical for business success. Surprisingly, only 27% of companies utilize technology to enhance their supply chain operations. The inquiries from businesses are as follows: How to optimize labor costs? How to determine the best ways to distribute and warehouse inventory?

Top 8 Ways AI Is Transforming Logistics & Supply Chain Industry

AI in logistics plays a significant role by assisting executives in the consumer products industry in making decisions more quickly, precisely, and efficiently. This is made possible by its capacity to collect enormous, diverse data sets and then instantly evaluate the information to deliver insights.

Stay In the Know

Get Latest updates and industry insights every month.